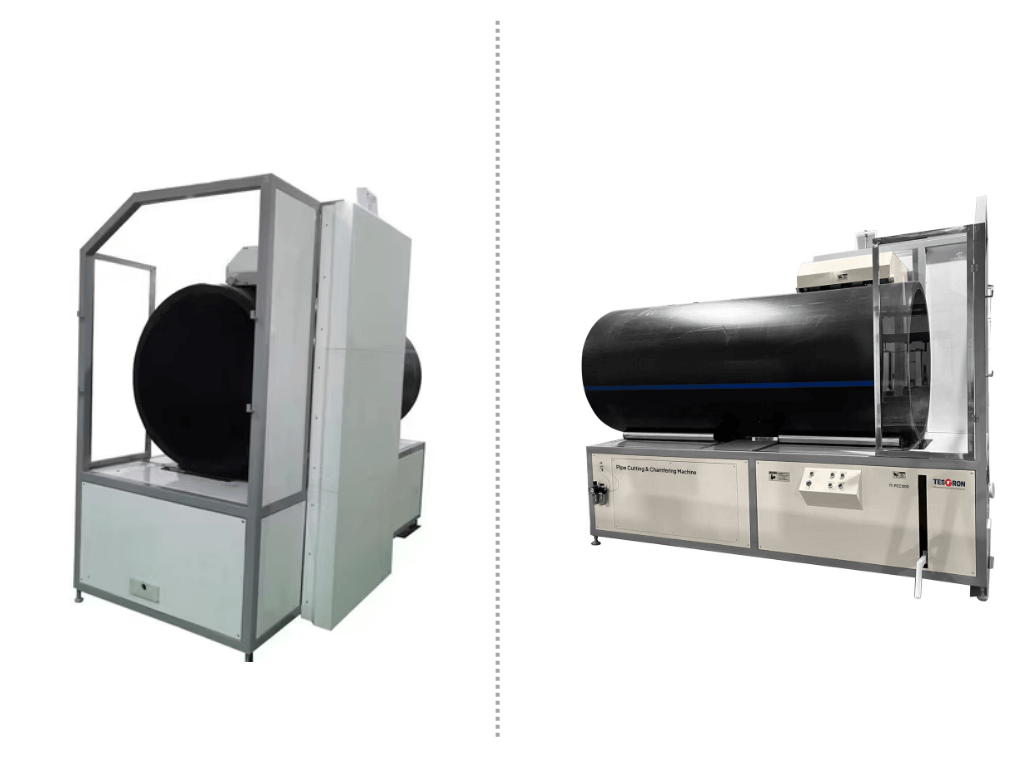

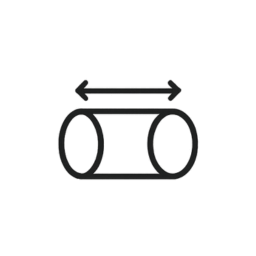

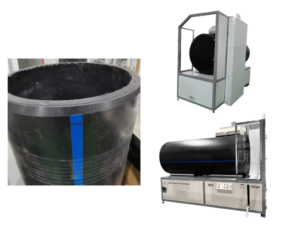

What makes the TT-PCC1200 unique is its ability to cut and chamfer simultaneously, reducing processing time and improving productivity. Designed with a planetary cutting method, pneumatic clamping system, and electronic soft start feature, it ensures smooth operations without compromising safety. Whether you are looking for the best pipe cutting machine for manufacturing or a pipe end chamfering machine for quality control testing , the TT-PCC1200 stands as a reliable investment.

For pipe manufacturers and testing laboratories, choosing the right equipment is crucial . With ISO1167, ASTM D1598, and ASTM D1599 compliance, this machine guarantees international standards of precision. From small pipe cutting and chamfering machines to large scale industrial systems, the TT-PCC1200 redefines versatility and performance in pipe processing.

TECHNICAL PARAMETERS TT-PCC1200 PIPE CUTTING & CHAMFERING EQUIPMENT

- Diameter range: Φ90 to Φ1200mm

- Pipe Wall thickness: 80 mm

- The chamfering angle: 15°

- Dimension: 1580mm×1030mm×1830mm

- Power: 380V 50HZ 2kW

KEY FEATURES OF TT-PCC1200

Wide Application Range

Suitable for pipes from 90 mm to 1200 mm in diameter.

High Wall Thickness Capacity

Handles pipe wall thicknesses up to 80 mm.

Automatic Protection & Safety

Motor only runs after clamping, prevents accidental mishaps

Planetary Cutting Technology

Ensures smooth, accurate cuts without pipe deformation

Synchronized Cutting & Chamfering

Increases speed while maintaining precision.

Electronic Soft Start

Reduces electromagnetic shock and power surges.

These features make it the best pipe cutting & chamfering machine for large scale industrial use as well as specialized testing environments.

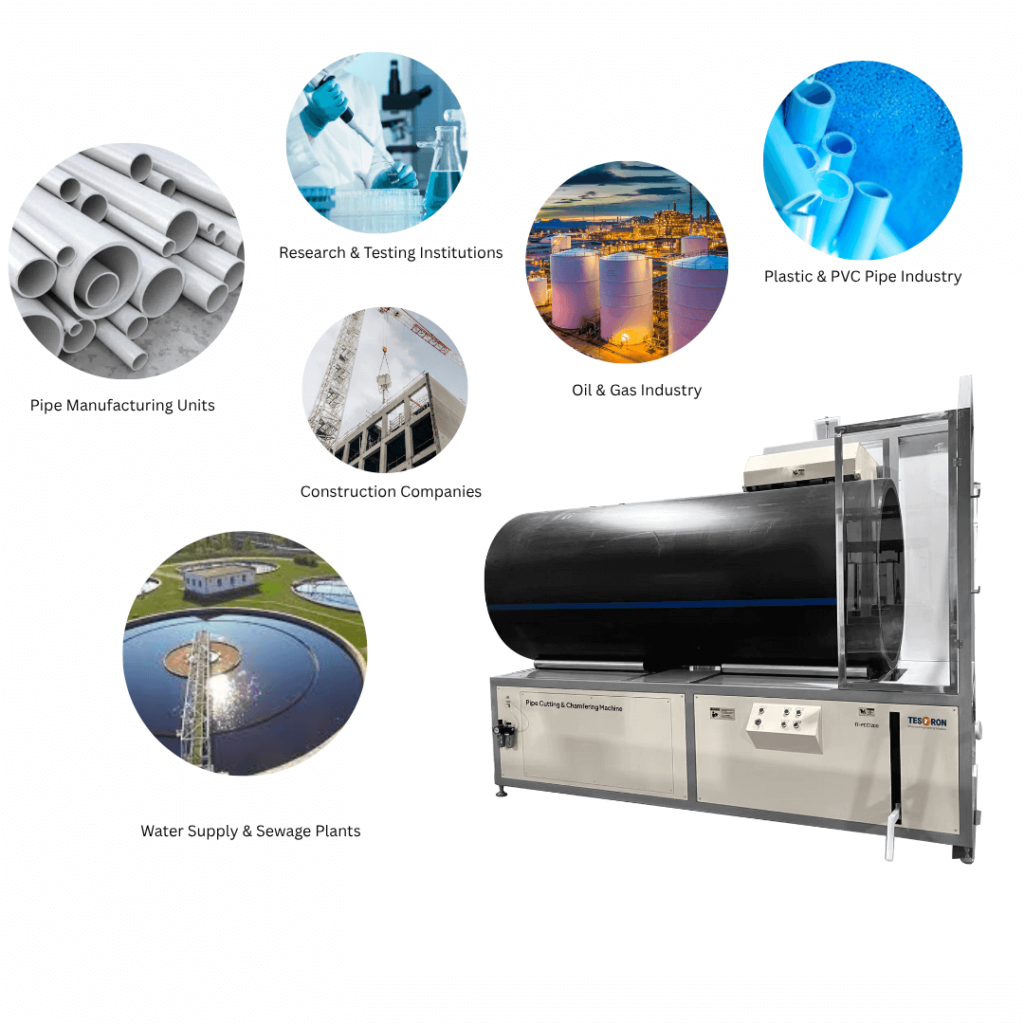

APPLICATIONS OF TT-PCC1200 PIPE CUTTING AND CHAMFERING MACHINE

The pipe testing equipment TT-PCC1200 is used widely across industries due to its adaptability and precision :-

- Pipe Manufacturing Units :- For accurate cutting and beveling before joining.

- Research & Testing Institutions :- To prepare samples for hydrostatic pressure testing and tensile testing.

- Construction Companies :- For on site cutting and pipe preparation.

- Oil & Gas Industry :- Prepares pipes for welding in high pressure pipelines.

- Water Supply & Sewage Plants :- Ensures durable connections in infrastructure projects.

- Plastic & PVC Pipe Industry :- For preparing samples during extrusion production lines

CHOOSING THE BEST PIPE CUTTING AND CHAMFERING MACHINE

When selecting a pipe cutting machine and chamfering equipment, here are key factors to consider :

- Pipe Diameter Range : Choose a machine that matches your production needs ( TT-PCC1200 handles up to 1200 mm ).

- Cutting Method : Planetary cutting ensures higher precision and less deformation.

- Automation Level : High automation reduces operator fatigue and errors.

- Safety Features : Auto stop, pneumatic clamps, and protective systems ensure operator safety.

- Budget & ROI : Consider both the pipe cutting and chamfering machine price and the long term cost savings.

- Compliance Standards : Machines must meet ISO and ASTM testing requirements.

.

The TT-PCC1200 Pipe Cutting Machine uses a pneumatic clamping system to hold the pipe securely before initiating the cut. Once clamped, the planetary cutting blades rotate around the pipe, ensuring a uniform cut without distortion. Simultaneously, the pipe chamfering machine‘s function smoothens the edges at a 15° angle , preparing the pipe for safe welding or pressure testing.

This dual function process significantly reduces cycle time and operator workload, making it far superior to traditional cutting pipe machines that only perform one function at a time.

Pipes are a backbone of industries such as construction, oil & gas, water supply, sewage, and telecommunications. Precise cutting and chamfering are essential for:

- Ensuring proper fit and welding during installation.

- Reducing risks of leaks , cracks, and joint failures.

- Meeting ISO and ASTM standards for product quality.

- Enhancing safety during pressure testing and long term use.

A high-quality machine like the TT-PCC1200 eliminates human error, increases accuracy, and boosts production line efficiency.

- Plastic Pipe Manufacturers

- PVC, HDPE & PPR Pipe Plants

- Oil, Gas & Petrochemical Companies

- Municipal Water Supply Departments

- Sewage & Drainage Infrastructure Projects

- Construction Contractors

- Testing & Research Labs

This wide range of applications makes it one of the best pipe cutting machines available in the global market.

COMPARISON: MANUAL CUTTING VS. TT-PCC1200

Aspect | Manual Pipe Cutting | TT-PCC1200 Pipe Cutting & Chamfering Machine |

Accuracy | Highly dependent on operator | Consistent precision with automation |

Speed | Slow, labor intensive | High speed synchronized cutting & chamfering |

| Safety | Risk of accidents | In built safety & auto stop |

| Pipe Size Capacity | Limited | Handles 90 mm :- 1200 mm |

Applications | Small workshops | Industrial manufacturing & testing |

| Cost Efficiency | High labor costs | Low maintenance & long term ROI |

Clearly, investing in an industrial pipe cutting machine like TT-PCC1200 ensures better efficiency and long term cost savings.

BUYING GUIDE: WHY TT-PCC1200 IS THE BEST CHOICE

If you are searching for the best pipe cutting and chamfering machine, the TT-PCC1200 stands out because :

- It’s designed for heavy duty industrial applications.

- Ensures international standard compliance.

- Offers a balance of efficiency, durability, and affordability.

- Suitable for pipe manufacturers, testing labs, and contractors.

Whether you need a small pipe cutting and chamfering instrument for lab use or a large industrial machine , Testron Group provides both standard and customized solutions.

PIPE CUTTING AND CHAMFERING MACHINE FREQUENTLY ASKED QUESTIONS

A pipe cutting and chamfering instrument is specialized equipment designed to cut pipes to precise lengths while simultaneously beveling (chamfering) the edges for welding or testing purposes.

The price varies depending on size, features, and customization. Testron Group provides cost effective options for both small and large scale needs.

The TT-PCC1200 pipe cutting machine is mainly designed for large plastic pipes such as PVC, HDPE, and PPR. For metal pipes, specialized machines are recommended.

Its planetary cutting technology, synchronized chamfering, wide size range, and automation make it the best pipe cutting or chamfering machine for industrial use.

Yes, Testron also offers small pipe cutting machine and chamfering machine for laboratory and small scale production.

Chamfering creates a smooth beveled edge that reduces stress concentration, prevents cracks, and ensures stronger welds during installation.