Rain and Spray Test Chamber Features:

- 2 rain nozzles for R1 R2 rain testing

- 40 spray nozzles for S1 S2 spray Testing

- Comply with JIS D 0203 test standard

- Flowmeter to control the water pressure

- Water Re-circulation System

- Automatic water supply ensures the adequate supply of water and automatic testing

- The internal material is 304 stainless steel, mirror surface

- Programmable color display touch screen controller

- USB and Ethernet

- A viewing window with a wiper

- Standard and customized

- CE ROHS mark

- It is mainly applied to the automobile industry

Rain and Spray Test Chamber Model:

| Model | R-1000JIS |

| Internal Dimensions (mm) | 1000*1000*1000 D*W*H |

| Overall Dimensions (mm) | 1100*1460*1900 D*W*H |

| Interior Volume (L) | 1000 |

| Distance from Specimen to Nozzle | Approx.400mm |

| Rain Nozzle | 2 holes |

| Rain Nozzle Hole | Φ0.5mm |

| R1 Water Flow Rate | 1.9L/min. |

| R2 Water Flow Rate | 3.3L/min. |

| Spray Nozzle | 40 holes |

| Spray Nozzle Hole | Φ1.2mm |

| S1 Water Flow Rate | 24.5L/min |

| S2 Water Flow Rate | 39.2L/min |

| Water Pressure at Nozzle | 0.03 ~ 0.30MPA |

| Turntable Rotation Speed | 17r/min |

| Water Pressure Control | Flowmeter |

| Controller | Programmable color LCD touch screen controller |

| Safety Device | Over-temperature Protection; Over-current Protection;Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

| Exterior Material | Steel Plate with a protective coating |

| Power Supply | 380V 50Hz |

| Standard | JIS D0203 |

Rain and Spray Test Chamber Accessories:

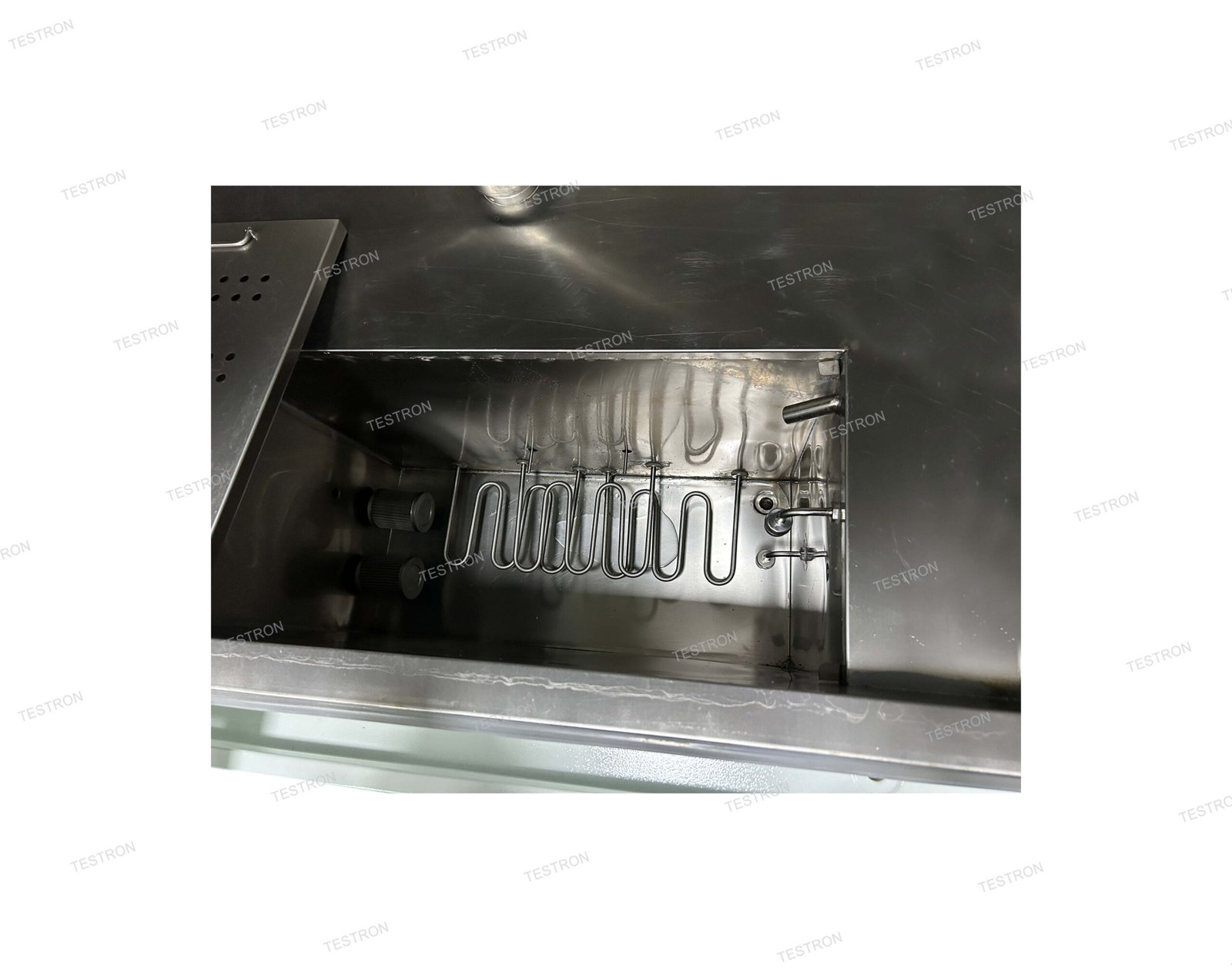

Workroom

Workroom

The internal material is 304 stainless steel, mirror surface, rust-proof, high temperature and corrosion resistance; Nice ruggedness and long life.

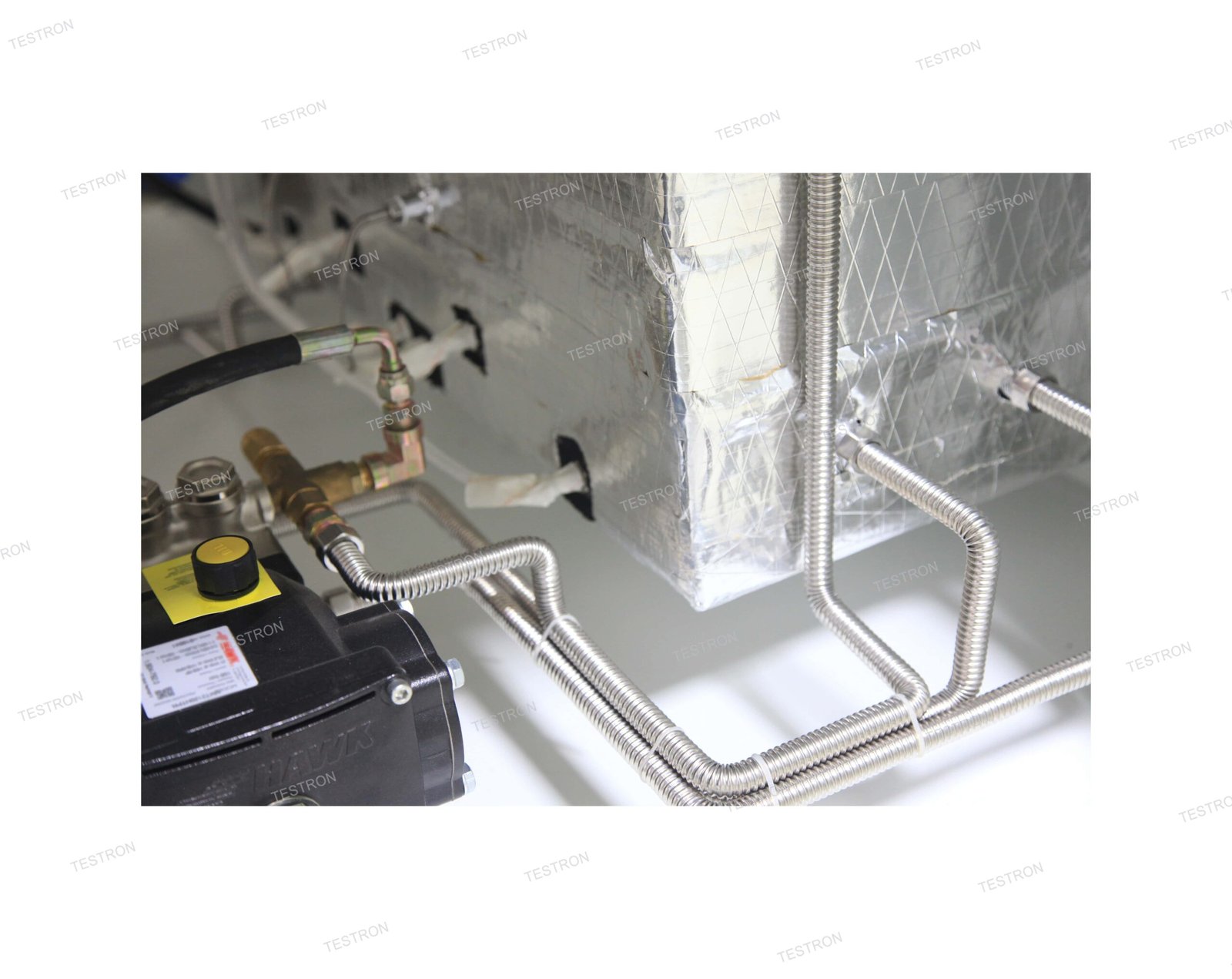

Flow Pipe

Flow pipe is made of stainless steel. Flow pipe shall be rotated around the axis X-S at the rate of approximately 23r/min.