Environmental and Climatic Test Chambers

TESTRON would like to introduce our range of advanced Environmental control chamber that is capable of simulating a wide range of temperature, humidity, Corrosion, Weathering, IP, and other environmental conditions.

Our high-quality environmental chambers and climatic test chambers are used in various industries, such as automobile, aerospace, materials, electronics, military, paintings, plastic, metal, battery, cable, PV solar panels, pharmaceuticals, navigation, and other industries.

Quality and Standards

We provide 3 years warranty and Lifelong follow-up services.

All our equipment meets CE and ROHS test standards

Accept third-party inspection, such as SGS, TUV, CSA, CE, ROHS, ISO17025 and etc. inspects on the electric system, material, accessories, and whole machines.

Our Environmental and Climatic Chambers Includes:

1. Temperature Climatic Test Chamber

Temperature Test Chamber

To perform cold resistance test, thermal cycling test, ultra low-temperature test, high-temperature test, storage condition, and calibration function. It is designed for quality inspection for all types of electronic products, electric appliances, and products from communication, instruction, automobile, plastic, metal, food, chemical, building materials, medical and aerospace industries

Temperature change rates from 1 to 15°C/min.

Low temperature available: A: -20℃, B: -40℃, C: -70℃, D: -86℃. E:-200℃ (liquid nitrogen refrigeration)

Included are ultra low-temperature test chambers, fast temperature change rate chambers (15℃/min), and liquid nitrogen refrigeration test chambers.

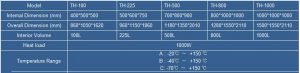

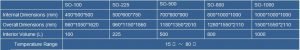

Model:

Temperature Humidity Test Chamber

Our Temperature and humidity test chambers are available in various sizes and configurations, ranging in size from 50Ltier to 3000Liter, including bench-tops, floor type, and walk-in. Floor types have more than 39 models to achieve various tests.

Temperatures ranging from -86°C to +150°C and humidity range from 20% to 98% RH.

To perform temperature & humidity tests, cold resistance tests, thermal cycle tests, ultra low-temperature tests, high-temperature tests, storage conditions, and calibration functions.

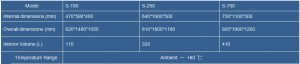

Model:

Benchtop Test Chamber

Bench-top temperature humidity test chambers are small test chambers for simulating temperature and temperature humidity environments.

Size available: 50 ~ 80 liters

Low types available -20℃/-40℃/-60℃/-70℃,10% – 98% RH.

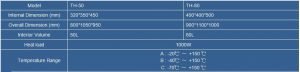

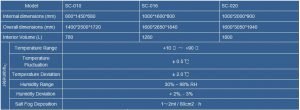

Model:

2-Zone Thermal Shock Test Chamber

2TS hot cold thermal shock test chamber is available in small capacity and large capacity to meet different testing requirements. The specimen automatically transferred from the cold chamber to the hot chamber with the help of a basket. This basket slides vertically and smoothly through rails, to make the specimen is exposed to the two chambers.

The thermal shock test chamber has been upgraded to a touch-screen controller with Ethernet, you are easy to operate over the network.

High/Low-Temperature control with fast Change rate

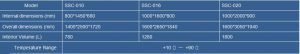

Model:

3TS Series Thermal Shock Test Chamber

3TS series thermal shock test chamber is just one chamber for the test room, it circulates cold and hot air through the pneumatic damper on the left and right sides. This design makes the external size smaller, and this 3TS series thermal shock chamber is pre-heated and pre-cooled to achieve faster test temperature.

The test chamber can pre-record the programs. So that customers can start test only by clicking the program numbers. Standard and custom models meet different requirements.

High/Low-Temperature control with fast Change rate

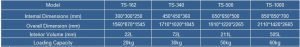

Model:

Environmental Test Chamber for PV Solar Panels

This performs PV modules (solar panels) thermal cycling, humidity freeze cycle, and damp heat RH testing and confirms whether PV modules can withstand high temperature with humidity and low temperature. It also tests fatigue and thermal failure after temperature repeated changes, test thermal Stress PV modules generated under high humidity circumstances, and capability of long-term resistance to moisture penetration.

Heating/Cooling rate: 1~3.4C/min with adjustable

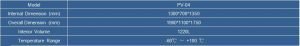

Model:

Cryogenic Chamber

This chamber adopts a mechanical compressor refrigeration system, cascade refrigeration, three refrigerants, instead of traditional liquid nitrogen refrigeration.

The lowest test is -120℃

The equipment size is available: 100L, 225L, 500L, 800L, 1000L.

Can be customized design and production according to customer requirement

Mainly used in high-precision fields such as aerospace, military, electronic component testing, and the quenching process industry of high-end processing industries

Model:

Industry Dry Oven

This oven is used for high-temperature drying, paint drying, drying glass and plastics, ink, and removing moisture, wood drying, and high-temperature tests. Applied to aerospace, automotive, electronics, metal industries

Drying ovens are available in various sizes and temperature ranges, including standard and custom ovens.

Ranging in size from 30 liters to 1000liters, including bench-top and standard type

Temperatures up to +250°C, +500°C, +800°C, +1000°C, +1200°C with small, medium and large volumes.

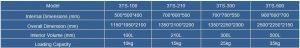

Model:

2. Corrosion Test Chamber

Salt Spray Test Chamber

Temperature control + Salt spray

The salt spray test chamber is used to test the anti-corrosion quality of all the materials surfaces of painting, coating, electroplating in the condition of salt spray environment.

Basic salt spray test chambers meet ASTM, ISO, IEC, and other International Standards test methods and capacity available in 108L, 320L, 410L, 780L, 1000L, 1600L capacity.

Model:

Cyclic Corrosion Test Chamber

Temperature control + Salt spray + Humidity control

The cyclic salt spray chamber is different from the basic salt spray test chamber. Cyclic corrosion test chamber exposes the sample to a series of different environments in repetitive cycles that incorporate temperature, humidity, salt spray, and dry.

Accelerated corrosion test methods included ASTM B117, ASTM BG85, ISO9227, IEC60068-2-52, IEC61701-2, ISO7253 and many others.

Model:

Salt Fog SO2 Spray Cyclic Corrosion Test Chamber

Temperature control + Salt spray + Humidity control + SO2

Salt and SO2 spray test chamber can determine the corrosion resistance of iron metal or the iron metal inorganic film or organic film test, such as car rear-view mirror, car audio, automotive electronics, automotive lighting. The interior testing machine can be customized according to customers’ special applications and requirements.

Model:

Ozone Resistance Test Chambers test elastomers (rubber) in the condition of ozone exposure, to simulate and measure rubber aging by means of ozone within a few days. Built with dynamic and static sample holders and others in accordance with the test method of ASTM D1149, IEX6006811-403, ISO1431, ASTM D1171. All models are upgraded to a programmable controller and Ethernet access that provides simple operation and control.

Model:

SO2 Noxious Gas Test Chamber can be used to test the product’s resistance to gas corrosion by simulating gas corrosion environments. SO2 Noxious Gas Test Chambers reproduce damages by temperature, relative humidity, and noxious gas corrosion to the material.

This noxious gas chamber can be used for single gas tests and mixed gas tests. Test methods are in accordance with IEC 60068-2-42, IEC60068-2-60, and other standards.

Model:

3. Weathering Test Chamber

Xenon Accelerated Weathering Test Chamber

Xenon arc chambers reproduce weathering damage by sunlight, temperature, humidity, and water spray.

Xenon weathering test chambers are utilized in textiles, dyes, leather, plastics, paints, coatings, automotive interior parts, electrotechnical products, color building materials. To perform weathering test, colorfastness tests, aging test, hardening test, softening test, crack.

Xenon weathering test chamber can place 42 pieces of specimens, are upgraded to programmable controller and Ethernet access. Their reliable performance and low purchase price make these products very competitive.

Model:

UV Weathering Test Chamber simulates ultraviolet radiation in natural light by using a fluorescent ultraviolet lamp as a light source. UV weathering resistance test chamber is used in tests that incorporate UV light, temperature, condensing humidity, water sprays, and irradiance control. Accelerated weathering tests included color change, gloss loss, chalking, cracking, crazing, hazing, blistering, strength loss and oxidation, and many others.

The shorter the wavelength, the higher the energy contained, the more likely it is to break the chemical bonds of molecules. UV energy is very high, as long as the energy reaches or exceeds the bond energy of polymer chemical bonds, it is enough to break the chemical bonds of polymers, leading to the decomposition of polymers.

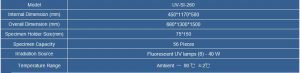

Model:

4. IP Test Chamber

Dust IP test equipment is made for the simulation of dust and sand conditions. These dust IP test chambers are used to test the exposure of automotive and electronic components under extreme environmental conditions in order to validate product seals. Dust ingress test methods included IEC60529, ISO20653, and many others.

IP5X IP6X Sand and Dust IP Test Chamber are available in various sizes 800liters 1000liters, 1500liters, 2000liters, and larger volumes. Considering that some specimens are small and large, so we designed and produced different sizes and configurations.

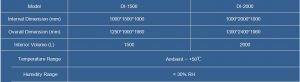

Model:

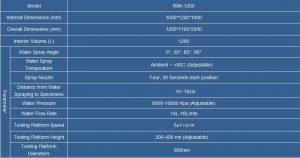

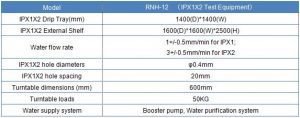

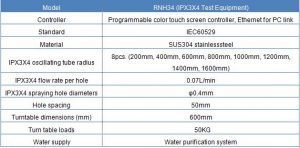

Water Spray Test Chamber (IPX1 IPX2 IPX3 IPX4)

The water ingress protection test chamber is used to perform the tests for testing the degree of protection provided by a product enclosure. The level of protection against water ingress is represented by an IP code. All our test chambers fully comply with IEC 60529 (IP Code standard) and other international standards.

The chambers are built with the water-tightness of sealed components such as headlamps, Power connectors. A waterproof power connector in the test room can easily supply electricity to the specimens.

Model:

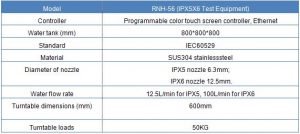

Water Jetting Test Chamber (IPX5 IPX6)

IPX5 IPX6 Water Jetting Test Chamber test and evaluate the protection degree provided by a product enclosure. The protection level against water ingress is called IP code, IPX6 Jetting Test equipment adopts a nozzle spraying water (IPX5:Ф6.3mm, IPX6:Ф12.5mm) against enclosure from every direction which should have no harmful effects, and strictly follows IEC60529 standard.

The chambers are built with the water-tightness of sealed components such as headlamps, Power connectors. A waterproof power connector in the test room can easily supply electricity to the specimens.

IPX5 and IPX6 function on one test chamber, make testing convenient and cost-effective.

Model:

Water Immersion Test Equipment (IPX7 IPX8)

IPX7 IPX8 water immersion tank is used to test the water-tightness of enclosures of automotive parts, outdoor lamps, and electronics parts.

IPX7 IPX8 immersion chamber built with a water re-circulation system that reduced water use and a series of water pipes. An automatic water supply ensures the adequate supply of water and automatic testing.

IPX7 and IPX8 function on one test chamber, make testing convenient and cost-effective.

High-Pressure Water Spray Test Chamber (IPX9K)

IPX9K high-pressure water spray test chamber is widely used in the electronics, military, and consumer product industries. IPX9K is the highest rating currently available for water ingress protection in accordance with IEC 60529 and ISO 20653.

Products under test are subjected to high pressure (8000 – 10000 Kpa), high temperature (+80°C), and water jets at a flow rate of 14 – 16 L/min.

IPX9K steam jet cleaning chamber built with a water re-circulation system that reduced water use and a series of water pipes. An automatic water supply ensures the adequate supply of water and automatic testing.

All models are upgraded to a programmable controller and Ethernet access that provides simple operation and control.

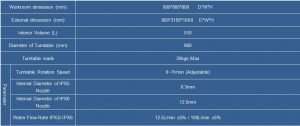

Model:

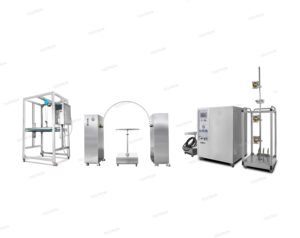

A Whole Set of Water Ingress IP Test Equipment -No Housing Type

A Whole Set of Water Ingress IP Test Equipment -No Housing Type is mainly used in automobile, electronics, military industry, for testing the waterproof performance of the protective material by simulating the natural wind and sand. The main components are communication equipment, outdoor lighting, auto parts, motorcycles, and other products.

Model:

TESTRON climatic test chambers, we deeply realized that quality is the first and most. Our chambers are building with high-quality materials, electronic parts, controller, compressor, solenoid valve, pumps, lamps, accessories, and many assembly parts of the products. We guarantee delivery on time.

Contact our team to learn more about our machines and services info@testrongroup.com