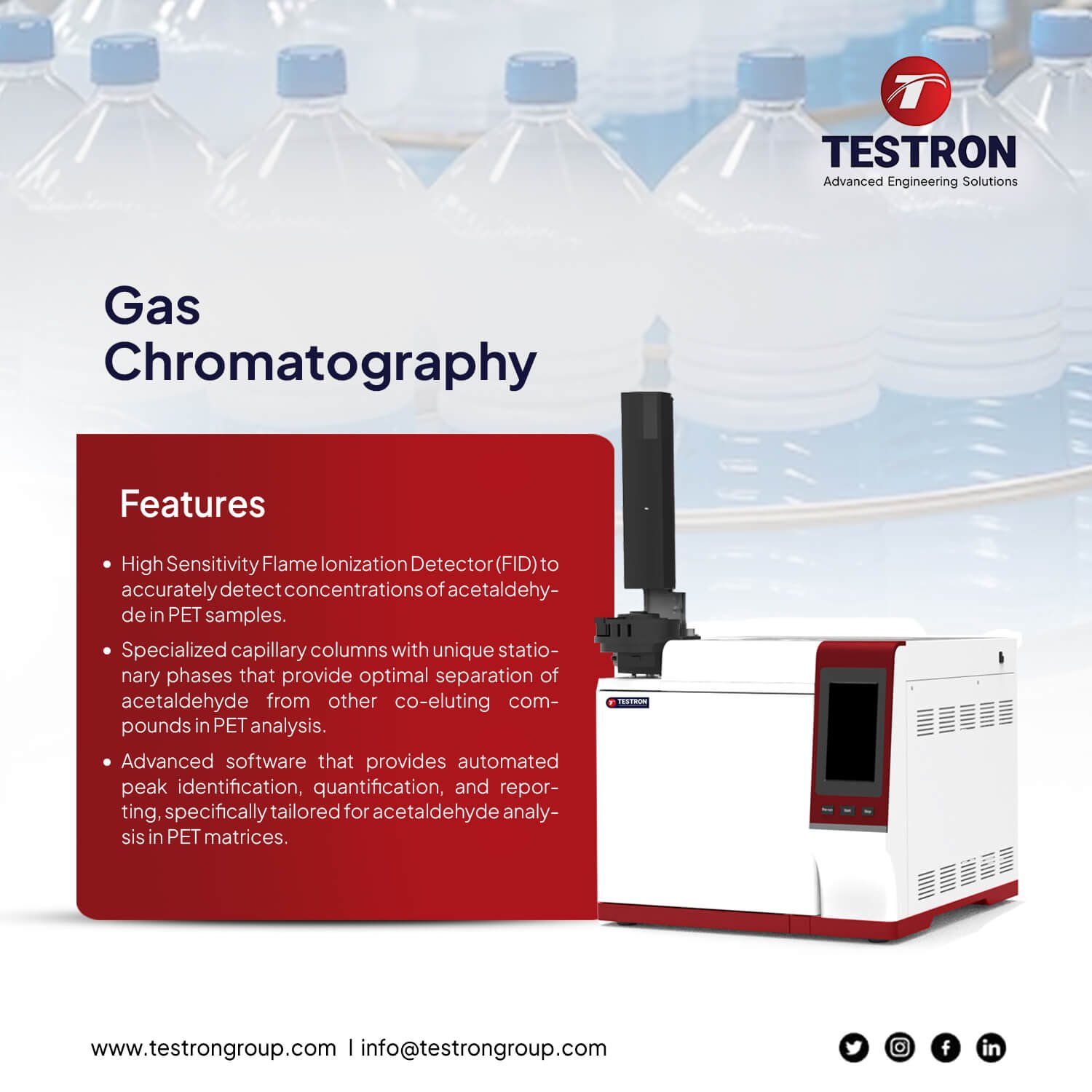

Application of TT PET-FID5220 Gas Chromatography

Polyethylene terephthalate (PET) bottles are widely used for beverage packaging. However, for the application of PET bottles as packaging material for mineral water, the acetaldehyde content of the bottle wall should be minimized. Acetaldehyde is a thermal degradation product of the PET polymer by the reaction of the vinyl end groups. If acetaldehyde migrates into the bottled water, it might influence the taste of the bottled water or beverage especially if it is carbonated.

The AA content of PET is generally determined using headspace gas chromatography. Since AA detection depends upon temperature and time, consistent instrument conditions must be defined for lab-to-lab comparisons.

Technical Parameter of TT PET-FID5220 Gas Chromatography:

1. Working condition

- Operating environmental temperature: 5~35 ℃.

- Operating environmental humidity: 5% ℃~95%RH.

- Operating voltage: 220V±10%, 50Hz±10%.

2. Chromatographic Performance

- Retention time repeatability < 0.008% or 0.0008min.

- Peak area repeatability<1% RSD.

- Supporting the installation of three injectors and four detectors.

- All injectors and detectors are controlled by electronic pressure/flow control, pressure control accuracy is 0.001psi.

- All electronic pressure/flow control modules provide back pressure compensation and temperature compensation, so that even if there are changes in the laboratory environment temperature/pressure, the instrument flow/pressure is not affected.

- The auxiliary electronic pressure/flow control module can provide 1-3 channel pressure control (AUX) and dual channel program control Gas flow path module (PCM).

- Supports the installation of 6 electronic flow control modules, providing up to 18 gas control channels.

- The liquid autosampler is fully compatible with the chromatography unit and software, without the need for additional software and hardware. It can provide 16-bit, 22 bit, and 24 bit liquid automatic sampler towers, and can expand to 150 bit and 161 bit sample trays. The liquid automatic sampler supports single tower and double tower injection.

- The display screen adopts a 7-inch touch screen with Raspberry Pi as the server and Linux system as the core. Developed based on the QT platform and using the MQTT protocol for communication, the page contains 9 interfaces, including status interface, analysis method, method configuration, instrument configuration, instrument diagnosis, hardware maintenance, instrument calibration, instrument log, and settings interface. The intelligent functional design includes diagnostic reminders, leak detection, carrier gas saving, etc., reducing the difficulty of use and maintenance, and easily grasping the status of the instrument.

- Ten gas chromatography machines were subjected to MTBF testing in accordance with T/CIS 03001.1-2020 “Verification Method for Mean Time Between Failures of Scientific Instruments and Equipment Reliability”. The cumulative operation time was 6020 hours, and the average time between failures was found to be over 5077 hours.

3. Column oven

- Operating temperature range: room temperature: +4℃ to 450℃,

- Temperature Setting Accuracy: 0.1℃, temperature control accuracy: 0.01℃,

- Supports 32 order column oven temperature gradient and 33 temperature platforms.

- Heating rate: ≥120℃/min, maximum operating time: 10000 min.

- Cooling time: from 450℃ to 50℃≤0 min.

- Environmental temperature impact: environmental temperature changes 1℃, the oven temperature change<01℃.

- Program heating repeatability: ≤5%

4. Injector

- Install number: maximum of three

- split/ spitless inlet

- Maximum using temperature: 450℃.

- Pressure setting range: 0~100psi, can update to 0~150psi, pressure control accuracy: ±0.001 psi.

- Suitable for all capillary columns (inner diameter from 0.1 mm to 0.53 mm).

- Split ratio: up to 12500:1, avoiding column overload.

- Equipped with septum blowing and sweeping, carrier gas saving mode, and self-diagnostic function.

- Chromatographic column flow control mode: constant pressure mode and program pressuring (10 orders) mode, constant flow mode or program flowing (10 orders) mode.

- Total flow setting range: N2: 0~200 mL/min;H2 (or He): 0~1000 mL/min.

- Septum and splitter plate support a tool free maintenance design.

- Packed injector

- Maximum temperature: 450℃.

- Pressure setting range: 0~100psi, can update to 0~150psi, pressure control accuracy: ±0.001 psi.

- Equipped with septum blowing and sweeping and automatic leak detection functions.

- Septum supports a tool free maintenance design.

5. Flame ionization detector (FID)

- Maximum temperature: 450℃

- Minimum detectivity: ≤1.5 pg /s (measured≤1.4 pg /s)

- Linear dynamic range: ≥107

- Data acquisition rate: 10/20/50/100/200 Hz

- Equipped with automatic ignition and flame extinguishing automatic protection functions.

6. Working station:

- Independently developed system layer control software with strong software compatibility, compatible with mainstream pre-processing devices and mass spectrometry detectors.

- The software supports over 10 languages.

- Control the complete instrument through a browser.

- Collection software: with real-time diagnosis and alarm functions: with carrier gas protection function.

- The instrument can achieve remote status monitoring and fault handling, and manufacturer engineers can remotely troubleshoot faults.

- The instrument workstation supports control of various terminal devices, such as computers, tablets, mobile phones, etc.

- A procedural and question answering instrument maintenance and testing interface guides users to quickly solve instrument failure problems.

7. Headspace Sampler

- Sample heating temperature range: 40℃-220℃

- Injection valve heating temperature range: 40℃-220℃

- Sample pipeline heating temperature range: 40℃-220℃

- Accuracy of control temperature: 1℃

- Vial Equilibrate time: 0-99.9min

- Pressure time: 0-9.99min

- Sampling time: 0-9.99min

- Quantitative volume: 1ml (500μL 3mL)

- Sample bottle size: 10ml or 20 ml

- Sample Vial: 10 or 12

- Heat Position: 12 (simultaneously heat and shake)

- MHE: 1-10

- RSD: ≤1.5% (100ppm ethanol-water solution)

- Consumption power: Max 350 W

- Outer dimension: 500×180×400 (mm)

- Net weight: About 18 Kg