Test Standards of TT-PCD300J Digital Pendulum Impact Tester

ASTM E23

Features of TT-PCD300J Digital Pendulum Impact Tester

- Displays real-time data, touch screen and physical button operation.

- Software supports multiple pendulums.

- Record impact strength, impact energy, etc. Maximum and minimum mean and standard deviation can be calculated.

- Experimental results are calculated automatically.

- Automatic measurement of swing period.

Technical Specifications of TT-PCD300J Digital Pendulum Impact Tester

| Model | TT-PCD300J |

| Impact energy | 150J, 300J |

| Pendulum pre-lift angle | 150° |

| Distance from center of pendulum shaft to impact point | 750mm |

| Impact speed | 5.2m/s |

| Span of sample support | 40mm |

| Rounded corner of pliers | R1mm |

| Impact blade rounded Angle | R8mm |

| Impact knife thickness | 16mm |

| Angle accuracy | ±0.1° |

| Sample size | 10mm×10mm×55mm |

| Overall dimension | 2124mm × 600mm ×2100 mm |

| Net weight of testing machine | 450kg |

| Power supply | AC three-phase 380V±10% 50HZ 5A |

| Environmental conditions | no corrosive medium in the surrounding environment, no vibration, no strong electromagnetic field interference |

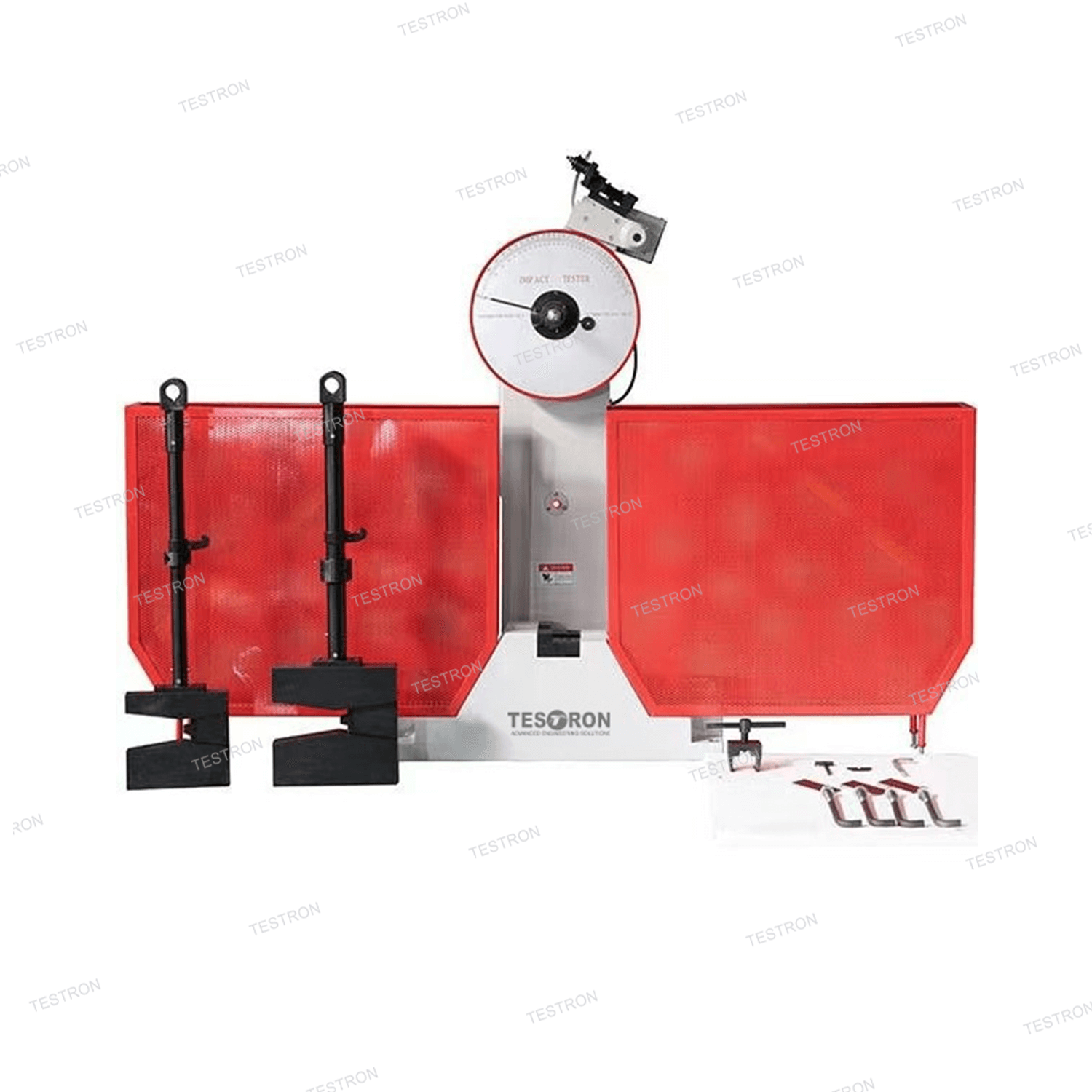

Standard Configuration of TT-PCD300J Digital Pendulum Impact Tester

| Item | Qty |

| 300 joule main machine | 1pc |

| 150J, 300J pendulum | 1 each |

| Motor (installed on the main engine) | 1pc |

| Pendulum transmission device (installed on the main engine) | 1set |

| Automatic hanging device (installed on the main engine) | 1set |

| Insurance organization (installed on the host) | 1set |

| Safety protection device; (fully enclosed protection) | 1set |

| Support adjuster | 1pc |

| Sample centralizer | 1pc |

| Photoelectric sensor | 1pc |

| Touch screen (7 inches) electric control cabinet | 1set |

| PLC system | 1set |