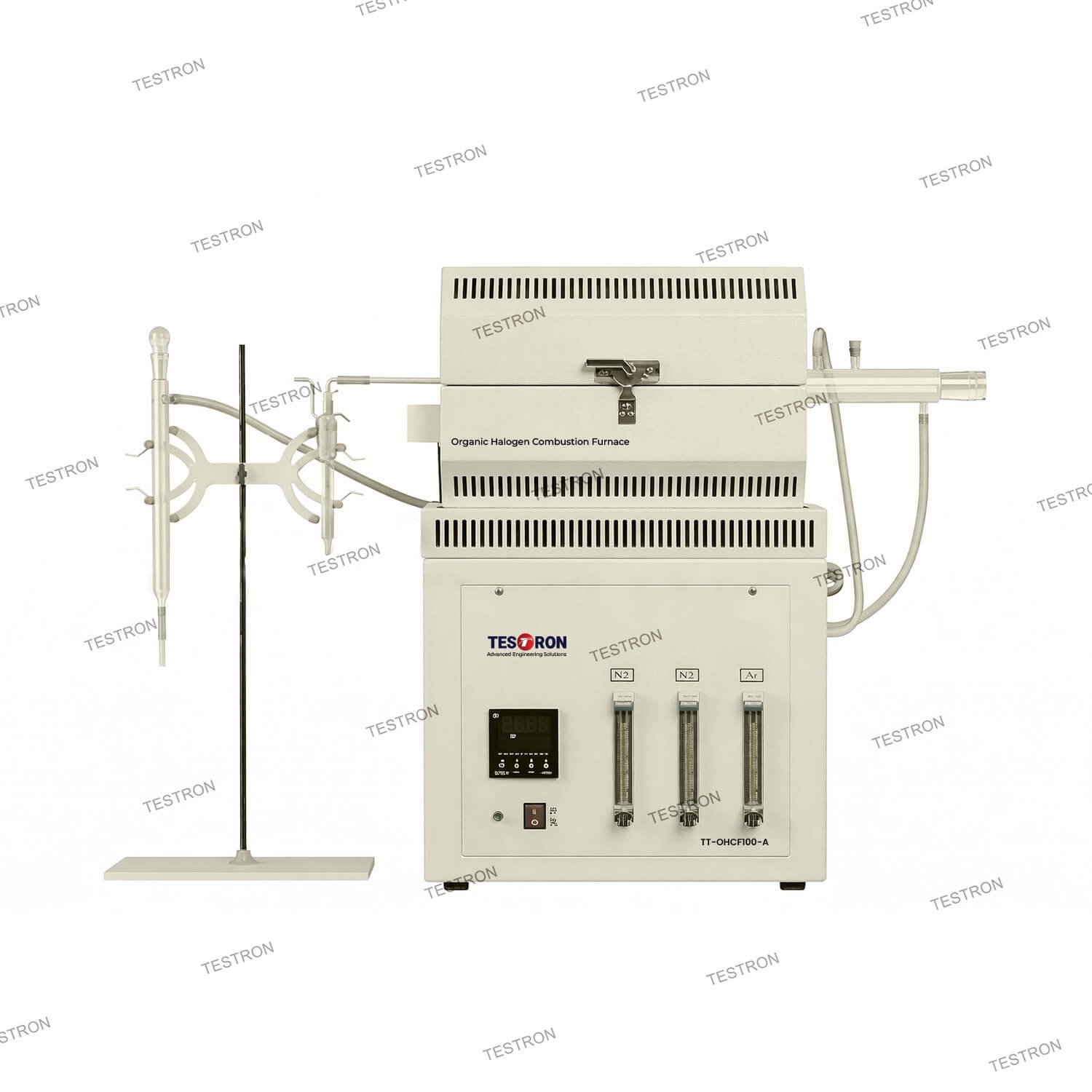

Application of TT-OHCF100-A Organic Halogen Combustion Furnace

It is specifically designed for the rapid and accurate detection of various types of organic halogens in a wide range of samples, including drinking water, surface water, groundwater, sewage, effluent, wastewater, tap water, brine, treated water, pulp discharge, soil, sediment, sludge, and waste oil.

Test Standard of TT-OHCF100-A Organic Halogen Combustion Furnace

H/JT 83-2001, ISO 9562:1989-09-01; GB/T 15959-1995, GB 8978-1996, GB3544-2008

Features of TT-OHCF100-A Organic Halogen Combustion Furnace

- Integrated design with a compact structure, small footprint, and user-friendly operation

- Rapid start-up time of less than 10 minutes, among the fastest in its class

- Fast and accurate analysis of both solid and liquid samples

- High-efficiency operation with direct sample injection onto the sample boat

- Low-voltage, high-temperature combustion furnace (220V, 1500W) to ensure long service life

- Designed for continuous 24-hour operation

- Simple and efficient structure with an openable design for easy observation of samples during analysis

- High activated carbon recovery efficiency

Technical Specifications of TT-OHCF100-A Organic Halogen Combustion Furnace

| Model | TT-OHCF100-A | ||

| Temperature range | 100 ~ 1150℃ | ||

| Fluctuation | ±1℃ | ||

| Display accuracy | 1℃ | ||

| Furnace chamber dimensions | φ40×300MM | ||

| External dimensions | 345*360*660MM | Net weight | 26kg |

| Heating area | 200mm | ||

| Compatible Furnace Tubes | AOX Combustion Tubes | ||

| 8 Heating rate | ≤50℃/min; (can be adjusted to any rate below 50℃/min) | ||

| Total power | 1.5KW | ||

| Power supply | 220V, 50Hz | ||

| Detection principle | High-temperature combustion method/ion chromatography (or micro coulometric method) |

| Combustion temperature | up to 1150°C |

| Sample pretreatment method | column adsorption method, nitrogen pressurization |

| Injection volume | 5-1000 mg |

| Detection range | 0.8 μg/L ~ 1000 μg/L |

| Average analysis time | 3-10 min (excluding sample pretreatment) |

| Gas | 99.6% oxygen (99.999% pure oxygen is optimal) |

| Online control and data processing software (optional) | |

Temperature Control System of TT-OHCF100-A Organic Halogen Combustion Furnace

| Temperature Measurement | K-scale nickel-chromium/nickel-silicon thermocouple |

| Control System | LTDE fully automatic programmable instrument, PID control, display accuracy 1℃ |

| Complete electrical system | Uses brand-name contactors, cooling fans, and solid-state relays |

| Time-based control | The heating time and constant temperature time can be set; the machine will automatically stop when the constant temperature time is reached |

| Over-temperature protection | Built-in two-stage over-temperature protection device, providing double protection. |

| Operating mode | Full-range adjustable constant temperature, constant operation; program operation. |

Furnace Structure and Materials of TT-OHCF100-A Organic Halogen Combustion Furnace

| Furnace shell material | The outer casing is made of high-quality cold-rolled steel plate, treated with phosphate coating and then powder-coated at high temperature; the color is computer gray. |

| Furnace liner material | It is made of two semi-circular composites of high-radiation, low-heat-storage, ultra-lightweight fiber molded together, with embedded high-temperature heating wires, resistant to rapid heating and cooling, and energy-efficient. |

| Insulation method | Air heat dissipation |

| Temperature measuring port | The thermocouple enters from the furnace opening; |

| Terminals | The terminals for the heating element are located on one side of the furnace opening |

| Controller | Integrated design, built-in control system, with compensating wires connecting to the furnace body. |

| Heating element | High-temperature resistance wire |

| Total weight | Approximately 25KG |

| Standard Packaging | Wooden Crate |

Standard Configuration of TT-OHCF100-A Organic Halogen Combustion Furnace

| Items | Qty |

| AOX Combustion Furnace (Used in HJ83-2001 ion chromatography) | 1 |

| Combustion tube | 1 |

| Sample boat | 2 |

| Quartz putter | 1 |

| rubber end cap | 2 |

| Nitrogen pressurization tube | 1 |

| Adsorption column | 1 |

| Nitrogen pressurization pipe fixing device | 1 |

| 15mm outer diameter silicone tube | 1.27 |

| Special gas washing bottle | 5 |

| Special absorption bottle | 2 |

| Special absorption tube | 2 |

| Specialized absorption bottle holder | 2 |

| Specialized absorption tube holder | 1 |

| gauze | 1 |

| Adhesive tape | 1 |

| Tie wire | 20 |

| Warranty Card | 1 |

| Instructional Manual | 1 |

| Operational Video | 1 |