High Temperature Failure Analysis

Creep occurs under load at high temperature. Boilers, gas turbine engines, and ovens are some of the systems that have components that experience creep. An understanding of high temperature materials behavior is beneficial in evaluating failures in these types of systems. Failures involving creep are usually easy to identify due to the deformation that occurs. Failures may appear ductile or brittle. Cracking may be either trans-granular or inter-granular. While creep testing is done at constant temperature and constant load actual components may experience damage at various temperatures and loading conditions

Creep of Metals

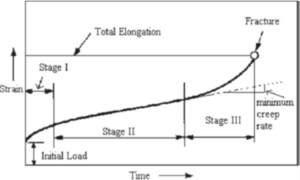

High temperature progressive deformation of a material at constant stress is called creep. High temperature is a relative term that is dependent on the materials being evaluated. A typical creep curve is shown below:

In a creep test a constant load is applied to a tensile specimen maintained at a constant temperature. Strain is then measured over a period. The slope of the curve, identified in the above figure, is the strain rate of the test during stage II or the creep rate of the material. Primary creep, Stage I, is a period of decreasing creep rate. Primary creep is a period of primarily transient creep. During this period deformation takes place and the resistance to creep increases until stage II. Secondary creep, Stage II, is a period of roughly constant creep rate. Stage II is referred to as steady state creep. Tertiary creep, Stage III, occurs when there is a reduction in cross sectional area due to necking or effective reduction in area due to internal void formation

Stress Rupture

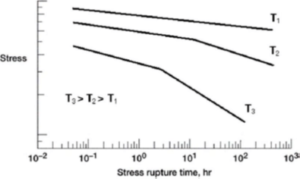

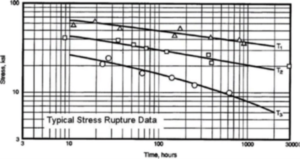

Stress rupture testing is similar to creep testing except that the stresses used are higher than in a creep test. Stress rupture testing is always done until failure of the material. In creep testing the main goal is to determine the minimum creep rate in stage II. Once a designer knows the materials will creep and has accounted for this deformation a primary goal is to avoid failure of the component.

Stress rupture tests are used to determine the time to cause failure. Data is plotted log-log as in the chart above. A straight line is usually obtained at each temperature. This information can then be used to extrapolate time to failure for longer times. Changes in slope of the stress rupture line are due to structural changes in the material. It is significant to be aware of these changes in material behavior, because they could result in large errors when extrapolating the data.

Test Standards of TT-CW Series High Temperature Creep Testing Machine

ISO/R 206, ISO 204, ASTM E139, HB5150-1996, HB5151-1996, JJG276, JB/T9373-1999

Application of TT-CW Series High Temperature Creep Testing Machine

TESTRON TT-CW Series High Temperature Creep Testing Machine is applicable to do creep test and durability strength test in the condition of high temperature for all kinds of metal and alloys materials. It is applicable to the field of quality measurement, aerospace, iron and steel metallurgy, machinery manufacturing, electronic appliances, automobile production, civilian nuclear energy, civil aviation, universities, research institutes, commodity inspection, arbitration and other industries.

Features of TT-CW Series High Temperature Creep Testing Machine

- Advanced servo motor and ball screw actuator which assures loading conveniently. It can transfer constant rate loading to constant-load or constant stain loading automatically.

- Motorized draw-head assembly automatically compensates for specimen elongation and keeps loading bar with excellent load accuracy of +/- 0.5% guaranteed.

- Both room temperature and elevated temperature systems are available.

- Furnace and chambers available with temperature ranges from 200 ℃ to 1000℃ in common air

- Environments, and 600 ℃ to 2200℃ available in vacuum environment.

- Numerous high temperatures pull rods, specimen holders, furnace systems and extensometers available for creep and stress Relaxation applications. Many of which are also adaptable to hot tensile testing applications on universal testing machines.

Technical Specifications of TT-CW Series High Temperature Creep Testing Machine

| Model | TT-CW10 | TT-CW20 | TT-CW30 | TT-CW50 | TT-CW100 | TT-CW200 | TT-CW300 |

| Load Frame | |||||||

| Max. load force (kN) | 10kN | 20kN | 30kN | 50kN | 100kN | 200kN | 300kN |

| Accuracy | ≤0.5% ; 0.5 class | ||||||

| Deformation accuracy | <±0.5% of reading | ||||||

| Loading speed | 0.05~50mm/min | ||||||

| Voltage | 220V/380V±10%;50Hz | ||||||

| Furnace | |||||||

| Operating temp. range | 300℃~1200℃ | ||||||

| Effective length constant | 150mm | ||||||

| Furnace inner dimension | Ф90*380mm | ||||||

| Furnace outer dimension | Ф320*460 (can be adjusted according to user needs) | ||||||

| Temperature control meter | · Yudian Temperature control meter · Electric conduction Temperature control meter | ||||||

| Thermocouple | · K type Even thermocouple · S type Even thermocouple (optional) | ||||||

| High temperature furnace accuracy (ºC) | · Test Temperature: 300~ 600 , Temperature: ±5, Temperature gradient: 3 · Test Temperature: >600~900 , Temperature: ±4, Temperature gradient: 4 · Test Temperature: >900~1100, Temperature: ±3, Temperature gradient: 5 | ||||||

Standard accessories of TT-CW Series High Temperature Creep Testing Machine

| Item | Picture |

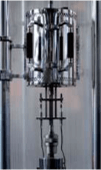

| High temperature pulling rod |   |

| Round specimen with screw head Φ5 specimen (M12) Optional M16 |   |

| Flat specimen with clevis couplings thickness 1mm~3mm (optional) |   |

| Pipe segment specimen with clevis couplings |   |

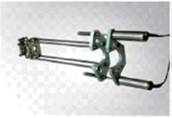

| Extensometer: Axial enter structure with LVDT outside LVDT Measuring range: 10 20mm LVDT accuracy: 3μm |   |