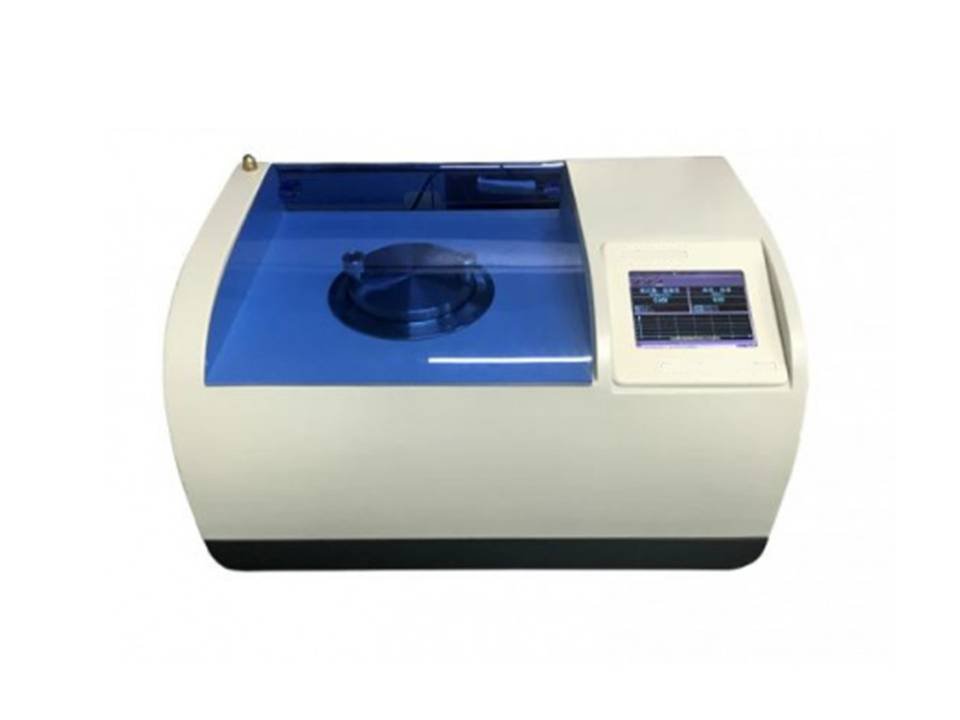

TT-Y110 Oxygen Permeability Analyzer Application:

1) Plastic film, composite film, aluminum foil, aluminized film, etc.

2) Sheet, panel, rubber, ceramics, etc.

3) Packaging containers, such as glass, bottles, cans, boxes, etc.

4) Expanding application: solar panel, LCD film, medical patch, etc.

Widely used in quality inspection organizations, drug control institutions, research institutes, packaging, thin-film, food companies, pharmaceutical enterprises, personal care industry, and electronics industry, and so on.

TT-Y110 Oxygen Permeability Analyzer Standard:

ASTM D3985, ASTM F2622, ASTM F1927,ASTM F1307, ISO 15105-2, DIN 53380-3,JIS K-7126-B, GB/T19789-2005, YBB00082003-2015,

TT-Y110 Oxygen Permeability Analyzer Specification:

| Item | Technical parameters |

| Test range | 0.02~16500 cm3/m2·24h(Film)With mask can be 260000 cm3/m2·24h |

| Test Accuracy | 0.001 cm3/m2·24h |

| Temperature range | 15~45℃ |

| Temperature accuracy | ±0.1℃ |

| Humidity range | 30~90%RH,100%RH |

| Humidity accuracy | ±1%RH |

| Test area | 50.24 cm2(minimum 0.785 cm2 optional) |

| Sample size | Φ100 mm |

| Sample thickness | ≤3mm |

| Number of samples | 1 piece |

| Carrier Gas pressure | ≥0.1MPa |

| Carrier gas port | Φ3mm gas pipe |

| Instrument size | 600×400×330mm |

| Weight | 80kg |

| Power | 750W |

| Power supply | AC 220V,50Hz |

TT-Y110 Oxygen Permeability Analyzer Features:

- Accurate and reliable data

- With The State Certificate for Gradation of the Certified Reference Materials and License for Manufacturing Measuring Instruments of the state Reference Materials (GBW(E)130497/8)of Oxygen permeability analyzer approved and issued by General Administration of Quality Supervision, Inspection and Quarantine of the P.R.C. Adopting state reference materials to calibrate and verify the instruments, ensure the accuracy, universality, and authority of the test data.

- Simple operation

- LCD and windows instrument interface show testing data and working status in real-time; mouse operation is simple and convenient.

- Professional software with a simple interface, easy to use, and convenient to set test process.

- Fully-auto operation, judge, and stop automatically.

- Real time curves display of transmission, oxygen concentration, temperature, and humidity, curves can be easily zoomed and moved. The curves with conceal function, support query function for background data.

- Professional test report; can be exported as PDF.

- Advanced technology

- Temperature control: International advanced electromagnetic technology, program controlled, auto heating and cooling; and no need of external accessories. Precision: 0.1℃.

- Humidity control: Dual gas flow method (dry gas and humid gas), with broad range, high precision (1%RH) and stable flow.

- Carrying cutting-edge ARM controlling system, can run independently without computer.

- High efficiency

- Measurement precise up to 0.001 cm3/(m224h), can test high barrier materials, such as aluminum foil.

- By adding package-testing accessories, can test oxygen transmission of various containers such as bags, bottles, can, and bowl.

- By adding adaptive accessory, can expand upper limit of test range to 260000 cm3/m224h.

- Calibration & Certification

- The instrument supports two methods of reference materials and standard gas to certificate and calibrate; Operation is simple, the user only need use certified reference materials for normal testing, and then input the test result into the instrument interface to complete calibration.

- Reliable and easy to maintain

- Imported oxygen sensor, with high precise and good performance, can work for a long time.

- Sensor over-range auto protection.

- Function modularization, easy to maintain.

TT-Y110 Oxygen Permeability Analyzer Configuration List:

| A, Spare parts | ||||

| NO. | Name | Remark | Quantity | |

| 1 | Power cable | 3*0.75 10A 1.8M | 1 PC | |

| 2 | Communication cable | RS232nine-pin data cable | 1 PC | |

| 3 | Sample cutter | Sample diameter 100mm(Tly-0.01) | 1 PC | |

| 4 | Sealing grease | HFV-GS(HFV-GS 70g) | 1 PC | |

| 5 | Metal gas pipe | 1/8“(0D)*2.1mm.SS316 | 5 M | |

| 6 | Ferrule connector | 1 piece of MC-01-01NPT 1/81 piece of MC-01-02 NPT 1/4 | 4 PCS | |

| 7 | Reference material | 125μm | 1 set | |

| 8 | Special spanner | M10 & M3 | 2 PCS | |

| 9 | Injection syringe | Medical disposable 1 ML | 1 PC | |

| 10 | Sealing circle | φ12 | 4 PCS | |

| 11 | Straddle wrench | 12mm | 1 set | |

| 12 | Cross screwdriver | 6-10mm | 1 PC | |

| 13 | Mouse | RAPOO M10 | 1 PC | |

| 14 | Wooden box | 1 PC | ||

| B, Optional parts | ||||

| NO. | Name | Unit | Quantity | Remark |

| 1 | Computer | Optional | ||

| 2 | Metrology Certificates | Optional | ||

| C, User provide | |

| 1 | Laboratory requirements: ordinary laboratory with air conditioner, temperature stale at 23°±2 |

| 2 | Experiment table requirements: table sizelength 200cm*width 80cm*height 80cm |

| 3 | Power supply:220V 1 piece of three-hole switch socket with three-position,10A |

| 4 | Computer requirements: standard configuration(Windows7, with nine-pin serial port) |

| 5 | 1 bottle of oxygen, purity must above 99.999%,with pressure reducing valve, output range is 0-0.4Mpa |

| 6 | 1 bottle of nitrogen, purity must 99.999%,with pressure reducing valve, output range is 0-0.4Mpa |