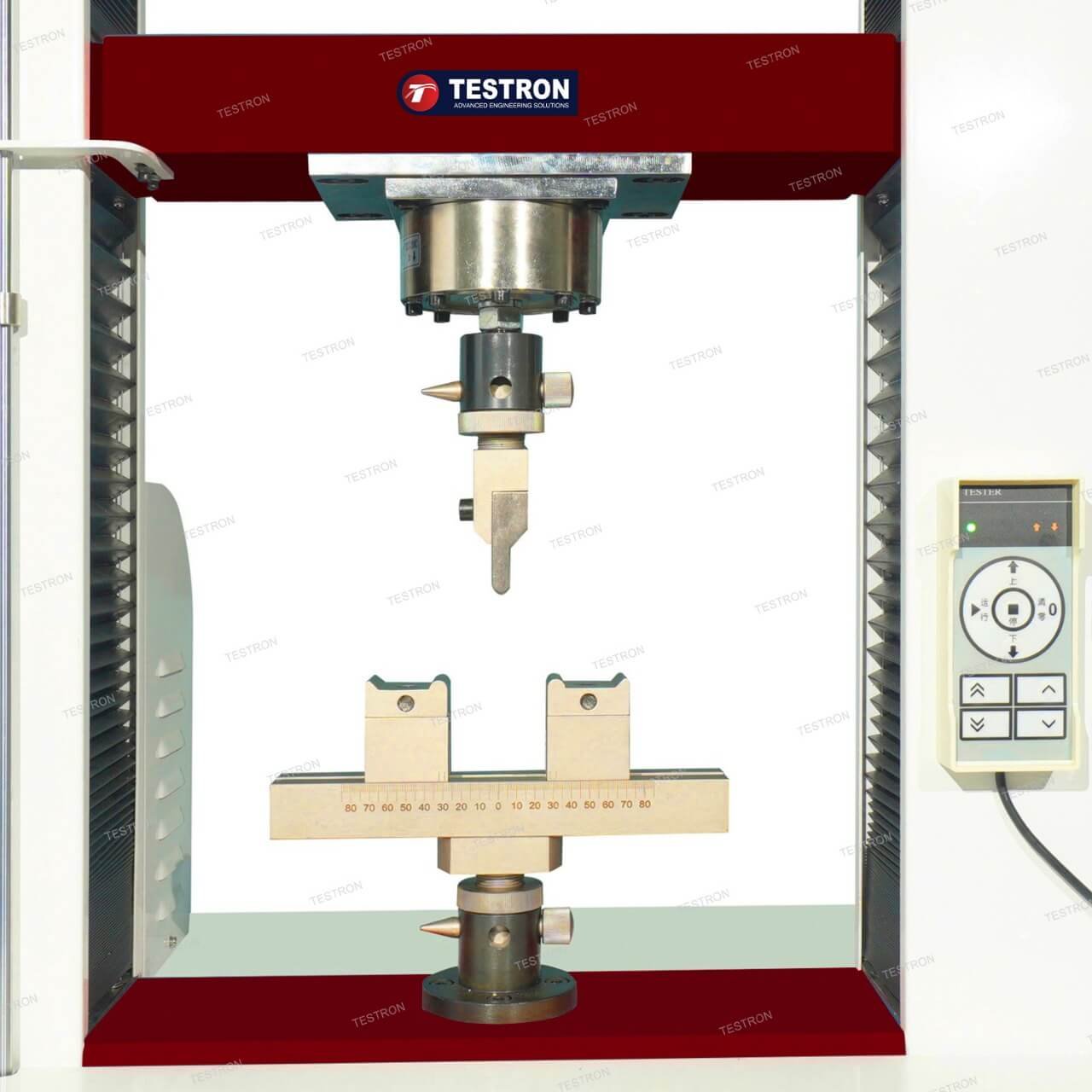

Universal Testing Machine Standards:

ASTM D 638, ISO 527, ISO 6259, ISO 6040, ISO 178, ISO 9969

Universal Testing Machine Features:

- Adapts double-column high rigid structure and seamless ball bearings.

- The test can be piecewise programmed by stress, strain, or displacement rate closed-loop controlling method.

- A high-quality load sensor realizes intelligent and digital control, largely increase the sampling accuracy and stability.

- Self-cleaning ball screws for fast, quiet testing with sealed for life lubricated end bearings; precise crosshead guidance system, smooth running.

- Cooperating with a large deformation extensometer, the yield strain, breaking strain, and strain at X% can be actually got.

- Modularization software includes almost all the mechanical property tests, may customize a new test module on the customer’s request.

Powerful Software functions

- Zeroing function will clear the initial stress of the specimen, acquiring a more accurate result.

- May plot Stress-Strain, Load-Displacement-Time, Stress-Time, Displacement-Time test curves.

- An embedded data analysis system will help the operator to analyze test data and contrast more test datum.

- Free upgrade software online.

Universal Testing Machine Technical specifications:

- Machine capacity: 10KN / 20KN / 30KN / 50KN

- Crosshead travel: 900mm

- Large deformation measuring range: 5~800mm

- Large deformation resolution: 0.0125mm

- Max. crossbeam speed range: 500mm/min

- Specimen width:400mm

- Power supply: 220VAC-15%~220VAC+10% 50Hz 1KW

Standard configuration

- Mainframe

- Application software

- Wedge tensile grip

- Extensometer for elongation test

- Desktop computer

Optional

- Compression grip

- Flexibility grip

- Ring stiffness grip

- Others on customer’s request