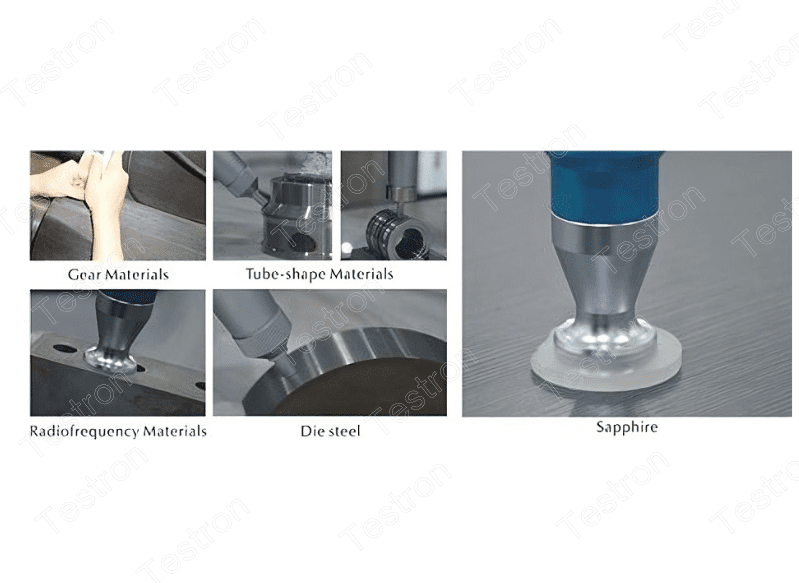

Application of TT-UCI100 Ultrasonic Hardness Tester

It is widely used to measure hardness of flange edges and gear root of stamping parts, molds, sheets, hardening surface of the tooth and gear and taper part hardness, hardness of the shaft, pipe including inside and outside wall, container, wheel, turbine rotor, bit blade, HAZ weld, printing roller, injection molding machine screw parts, small forgings, cast material, weld inspection, heat affected zone, Ion-nitride stamping dies and molds, forms, presses, thin-walled parts, bearings, tooth flanks, etc.

Probe Features of TT-UCI100 Ultrasonic Hardness Tester

- Advanced and latest ultrasonic sensor technology.

- Accurate hardness value without auxiliary devices.

- Supports 360° quick measuring.

- Ergonomically design – easy to hold.

- Lightweight probe which is convenient to control.

- Quick and accurate measuring for edge and fixed position of specimen.

- Micro indentation, non-destructive for specimen.

Technical Specification of TT-UCI100 Ultrasonic Hardness Tester

| Measuring range | HB: 76-618; HV 80-1599; HRC 20-68; HRB: 41-100; HRA: 61-85.6; Mpa: 255-2180N/mm |

| Measuring accuracy | HV:±3%HV; HRC:±1.5HRC; HB:±3%HB; HLD:±5HLD; |

| Hardness scale | HV, HB, HRC, HLD |

| Optional Force: | Manual Probe: 10N; 20N; 50N; 98N; |

| Indenter: | 136°Vickers Diamond Indenter |

| Measuring Direction: | Support 360° |

| Data Storage: | To save 1000-groups of measuring data and 20-groups of calibration data |

| Data Display: | Loading force, Testing-times, Testing result, Average, Maximum, Minimum, Deviation and Conversion scale. |

| Hardness Indication: | LCD Display |

| Data Output: | RS232 to Hyper Terminal |

| Operating Voltage: | DC 6V |

| Operating Environment: | Temperature: -10℃~50℃; Humidity: 30%~80%R.H |

| Dimensions: | 160x80x31mm |

| Net Weight: | about 500g (Without probe) |

Standard Configuration of TT-UCI100 Ultrasonic Hardness Tester

- Main Unit 1pc

- Ultrasonic Hardness Block (58~65) HRC 1pc

- 20N manual probe 1pc

- Probe Cable 1pc

- USB Charger with Cable 1pc

- COM Cable 1pc

- Screwdriver 1pc

- Toolbox 1pc

- Quality Certificate 1copy

- Operating Manual 1copy

- Warranty Card 1copy

Optional Accessories of TT-UCI100 Ultrasonic Hardness Tester

|  |

|  |