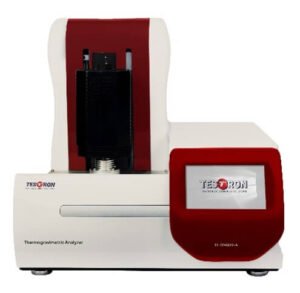

Application of TT-TGA1250-A Thermogravimetric Analyzer

It is widely used in the research and development, process optimization and quality monitoring of plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composite materials.

Features of TT-TGA1250-A Thermogravimetric Analyzer

- Furnace body heating adopts double row winding of precious metal platinum-rhodium alloy wire to reduce interference and more resistance to high temperature.

- Pallet sensors, made of precious metal alloy wire, have the advantages of high temperature resistance, oxidation resistance and corrosion resistance.

- Power supply, the circulating heat dissipation part and the main engine are separated to reduce the heat and vibration on the micro-thermal balance.

- Hosts use an isolated heating furnace to affect the heat of the chassis and the micro-thermal balance.

- Furnace body adopts double insulation, better linearity; the furnace body is equipped with automatic lifting, which can cool down quickly; it has a tail gas outlet, which can be used with infrared and other devices.

Advantages of controller and software

- Use imported ARM processors, sampling speed and processing speed are faster.

- The four-channel sampling AD collects the TG signal and temperature T signal.

- Heating control, PID algorithm is adopted for accurate control. It can have multi-stage heating and constant temperature.

- USB two-way communication is adopted between the software and the instrument to fully realize remote operation, and the parameter setting and stop of the instrument can be carried out through computer software.

- 7-inch full-color 24bit touch screen for better human-machine interface. Calibration of TG can be achieved on the touch screen.

Operational Principle of TT-TGA1250-A Thermogravimetric Analyzer

- Heating process

The sample is placed in a crucible in the heating furnace and heated or cooled at a certain rate through the programmed temperature control system. In this process, the sample will undergo a series of physical and chemical changes, such as water evaporation, organic decomposition, phase change, etc., which will lead to the reduction of the sample quality.

- Quality monitoring

The quality change of the sample is measured and recorded in real time by a high-precision balance. The balance converts the quality change into an electrical signal, which is transmitted to the recording system and finally displayed in the form of a curve showing the relationship between the quality and temperature or time.

- Data recording and analysis

The thermal stability, phase transition temperature, decomposition temperature and other characteristics of the samples can be analyzed by recording the quality change curve recorded by the system.

Technical Specifications of TT-TGA1250-A Thermogravimetric Analyzer

| Model | TT-TGA1250-A |

| Temperature range | Room temperature-1250℃ |

| Temperature resolution | 0.001℃ |

| Temperature fluctuation | ±0.01℃ |

| Heating/cooling rate | 0.1~100℃/min;-0.1~-40℃/min |

| Temperature control method | PID control, heating, cooling and constant temperature |

| Weighing system measurement range | 0.001mg~3g, which can be extended to 50g |

| Accuracy | 1ug |

| Resolution ratio | 0.1ug |

| The atmosphere was controlled | Three gas flow control |

| Software | The intelligent software can automatically record the TG curve for data processing, TG/DTG, quality, percentage coordinates can be switched at will; the software has automatic adjustment function, according to the spectrum display, automatic extension, zoom

|

| Constant temperature time | Any setting: standard configuration is less than 600min |

| The operating software has the corresponding copyright certificate, and the data test frequency can be selected in real time, 2S,5S,10S, etc | |

| The lifting furnace body is cooled through a water-cooling dust-free system, providing precise temperature control. It can perform measurements in various dynamic and static atmospheres. The furnace is equipped with interchangeable sensors that offer different temperature ranges and characteristics, and it supports the use of multiple types of crucibles to accommodate different sample properties. The heating time for 1000℃-50℃ is less than 20 minutes (air cooling + water circulation).

| |

| External water-cooling device to isolate the drift effect of heat on the weighing system; temperature range-10~60℃

|

Application Samples of TT-TGA1250-A Thermogravimetric Analyzer

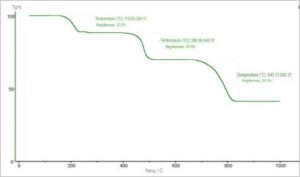

Calcium oxalate chromatogram for sample testing

Calcium oxalate exhibits three distinct stages of significant weight loss at RT-1000℃. The first stage marks the loss of water molecules, the second stage involves the decomposition of CaC2Q4 into CaCQ3, and the third stage is the decomposition of CaCO3 into CaO. As shown in the figure, at RT-300℃, calcium oxalate loses 12.31% of its water molecules. During the second stage, from 350℃ to 550℃, calcium oxalate begins to decompose and lose weight at a rate of 19.14%, resulting in a mass ratio of CaCQ3 of 68.55% (100% -12.31% -19.14%). In the third stage, from 600℃ to 850℃, it loses 30.74% of its weight, resulting in a mass ratio of calcium oxide of 37.81% (68.55% -30.74%) Sample test, rubber products spectrum

the third stage is the decomposition of CaCO3 into CaO. As shown in the figure, at RT-300℃, calcium oxalate loses 12.31% of its water molecules. During the second stage, from 350℃ to 550℃, calcium oxalate begins to decompose and lose weight at a rate of 19.14%, resulting in a mass ratio of CaCQ3 of 68.55% (100% -12.31% -19.14%). In the third stage, from 600℃ to 850℃, it loses 30.74% of its weight, resulting in a mass ratio of calcium oxide of 37.81% (68.55% -30.74%) Sample test, rubber products spectrum

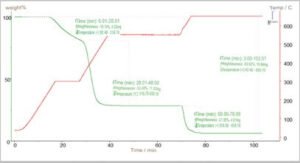

Thermal gravimetric method can quickly test the content ratio of various components in rubber according to ISO standard9924-1-2016 Rubber and rubber products. The thermogravimetric method is used to determine the composition of vulcanized rubber and un-vulcanized compounds, resulting in the above graph. In the first stage, the rubber shows a volatile weight loss of 19.14% at RT-316.7℃; in the second stage, from 316.7℃ to 550.10℃, the rubber begins to decompose, with an organic matter weight loss of 71.62% at RT-550.10℃; from 550℃ to 650℃, oxygen is passed through, causing carbon black to burn and lose weight, indicating that the carbon black content in the rubber is 21.95%.

Thermal gravimetric method can quickly test the content ratio of various components in rubber according to ISO standard9924-1-2016 Rubber and rubber products. The thermogravimetric method is used to determine the composition of vulcanized rubber and un-vulcanized compounds, resulting in the above graph. In the first stage, the rubber shows a volatile weight loss of 19.14% at RT-316.7℃; in the second stage, from 316.7℃ to 550.10℃, the rubber begins to decompose, with an organic matter weight loss of 71.62% at RT-550.10℃; from 550℃ to 650℃, oxygen is passed through, causing carbon black to burn and lose weight, indicating that the carbon black content in the rubber is 21.95%.