Application of TT-GTR110 Gas Permeability Analyzer

It is suitable for measuring the gas permeability of various plastic films (PP/PET/PE/PVC/BOPP/CPP, etc.), sheets, paper, and packaging materials across industries such as food, pharmaceuticals, medical devices, daily chemicals, and photovoltaic electronics, covering high, medium, and low barrier materials.

Test Standards of TT-GTR110 Gas Permeability Analyzer

ISO 2556, ISO 15105-1, ASTM D1434, JIS K7126-1, YBB 00082003, GB/T 1038

Features of TT-GTR110 Gas Permeability Analyzer

Patented core technology, efficient and accurate testing

- Patented automatic pressure differential technology, automatically maintains the pressure difference on both sides of the sample (pressure differential can be adjusted arbitrarily), built-in high-precision pressure sensor, resolution up to 0.01 Pa, good stability, low failure rate.

- The semiconductor refrigeration chip automatically controls the temperature in both directions, and the temperature control accuracy reaches 0.1℃.

- Original imported vacuum pump, the limit pressure can reach 0.1 Pa, high vacuum efficiency and low noise.

- The new pneumatic air circuit control system, the automatic clamp locks the sample with one button, which is convenient and labor-saving, and has excellent sealing performance.

Wide range and high applicability test requirements

- The test range is wide, and the test lower limit is as low as 0.01 cm3/ (m224 h·0.1 MPa), which can meet the test requirements of various high, medium and low barrier materials.

- Adding adapter accessories can measure the gas permeation of bottles, bags, bowls and other packaging. At the same time, it supports the permeability performance test of different gases such as oxygen, carbon dioxide, nitrogen, and air.

Excellent appearance, convenient operation, real-time visualization curve

- The product is designed from the perspective of ergonomics and technical aesthetics, with exquisite 3D printed shell and lines Smooth, stylish and beautiful, novel and unique.

- The instrument is fully automatic operation, one-button test, automatic judgment, automatic shutdown.

- Real-time display of six sets of curves including permeation-time, temperature-time, humidity-time, nitrogen flowtime, oxygen flowtime, and concentration-time. The curves support preview and hide functions.

Intelligent operating system, global certification

- Self-developed intelligent operating system, modular icons, stylish color matching, humanized settings, intuitive and convenient operation.

- According to the GMP appendix computer system design, the test process parameters can be set flexibly to meet different standard requirements.

- With audit trail (log trace, test trace) function, it can meet the needs of data traceability. Different levels of system operation authority can be set.

- Personalized test reports can be set on demand, data output in multiple formats, electronic signatures, and online submission of audit reports are supported.3

Professional calibration service, accurate and reliable data

- Our company has the gas transmission rate “National Standard Substance Grading Certificate” approved and issued by the “General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China”, the reference material number (GBW(E) 130497 / GBW(E) 130498); The national reference material is used to calibrate and test the instrument to ensure the accuracy, versatility and authority of the test data.

Laboratory Intelligent IoT Platform

- The instrument can be connected to the Internet of Things platform to realize network digital management.

- Remote authorization to log in to the IoT platform can realize functions such as managing experimental data, remotely diagnosing and solving faults.

- Customers can download the required instrument information, documents, and operation videos on the platform by themselves.

Technical Specification of TT-GTR110 Gas Permeability Analyzer

| Model | TT-GTR110 |

| Testing range | 0.01~50000 cm3/(m2·24 h·0.1 MPa) By expanding the volume limit, it can be tested 600000 cm3/(m2·24h·0.1MPa) |

| Testing accuracy | 0.0001 cm3/(m2·24 h·0.1 MPa) |

| Testing temperature | 15~60℃ |

| Temperature precision | ±0.1℃ |

| Vacuum | <10 Pa |

| Vacuum resolution | 0.01 Pa |

| Test Pressure | 0.1 MPa |

| Test Gas | O2, CO2, N2, etc |

| Permeation area | 50.24 cm2 |

| Sample size | Φ110 mm |

| Sample thickness | ≤2mm |

| Number of samples | 1 pc |

| Dimension | 380 mm x 585 mm x 345 mm |

| Weight | 25kg |

| Power | 450W |

| Power supply | AC 220V,50Hz |

Working Principle of TT-GTR110 Gas Permeability Analyzer

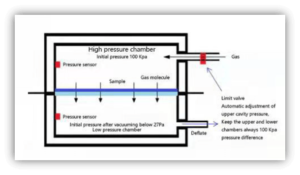

Gas Permeability Tester operates on the differential pressure method. The test sample is placed between the upper and lower chambers, and the system is evacuated with a vacuum pump. Experimental gas at atmospheric pressure is then introduced into the upper chamber, creating a constant pressure difference. Driven by this gradient, the gas permeates through the sample into the lower chamber. The system monitors the pressure change in the lower chamber to accurately calculate the gas permeability and barrier properties of the material.

atmospheric pressure is then introduced into the upper chamber, creating a constant pressure difference. Driven by this gradient, the gas permeates through the sample into the lower chamber. The system monitors the pressure change in the lower chamber to accurately calculate the gas permeability and barrier properties of the material.

Standard Configuration of TT-GTR110 Gas Permeability Analyzer

| Items | Items |

| Power line

| Sealing grease |

| Communication line | Qualitative filter paper |

| Special wrench | Philip screwdriver |

| Sampler | Reference film |

| Rubber hose | Threaded joint |

| Air pipe joint 1/8 | Sealing ring |

| Air pipe joint 1/4 | mouse |

| Warranty Card | Instructional Manual |

| Optional | |

| Computer | Air Compressor, Vacuum Pump |

User Provide of TT-GTR110 Gas Permeability Analyzer

- Laboratory requirements: general laboratory.

- Power requirements: one 220V three-hole three-position switch socket, 10A

- Computer requirements: standard configuration (Windows10, with a nine-pin serial port.)

- Requirements for experimenters: 1-3 test operators, certain computer knowledge

- Drying dish (all samples need to be dehydrated and degassed for 24 hours)

- Other accessories: used for calibration: a bottle of oxygen (above 99.999% purity), and other gases at your own discretion.