Digital Bursting Strength Tester Standards:

ASTM D2210, ISO 2759, GB/T 6545, JIS P8112, JIS L1018, TAPPI T403

Digital Bursting Strength Tester Specifications:

| Type | High pressure/ Low pressure/ Textile |

| Test speed | High pressure:170 ± 15 ml/min; Low pressure:95 ± 5 ml/minTextile:98 ± 4 ml/min |

| Pressure display | D1 Control touch panel |

| Capacity | 75 kg/c㎡ |

| Platen diameter-Upper | High pressure:31.5 ± 0.05 mm; Low pressure:30.5 ± 0.05 mmTextile:30.5 ± 0.05mm |

| Platen diameter-Lower | High pressure:31.5 ± 0.05 mm; Low pressure:33.1 ± 0.05 mmTextile:30.5 ± 0.05mm |

| Gear position | Pressurization, neutral, return |

| Features | 1. Using flow switch, and can switch to different speed of pressurization2. Equipped with a 7-inch touch screen, and show real-time pressure and bursting time3. Data exportable to USB |

| Dimension | 53 x 33 x 58 cm |

| Weight | 60 kg |

| Power | Single phase 110~240VAC,5A |

Digital Bursting Strength Tester Accessories

Rubber film low pressure

This accessory for the bursting strength test is placed under the test specimen plate. After pressurization, the glycerin will hold up the rubber film and then break the test specimen.

This is a test consumable that will be fouled, fatigued or broken when used for a period of time and will need to be replaced if necessary.

Note: Low pressure rubber film is applicable to the range 0~10kgf/c㎡

Rubber film high pressure

This accessory for the bursting strength test is placed under the test specimen plate. After pressurization, the glycerin will hold up the rubber film and then break the test specimen.

This is a test consumable that will be fouled, fatigued or broken when used for a period of time and will need to be replaced if necessary.

Note: High pressure rubber film is applicable to the range 6~75kgf/c㎡

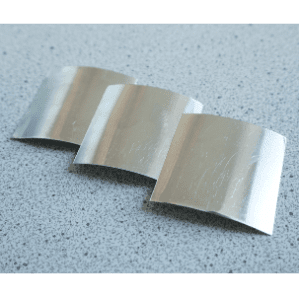

Aluminum foil

Standard sheet for calibration.

Regular use of standard aluminum foil to check the condition of the testing machine. If the deviation is too large, it is recommended to replace a new rubber film.