Dichloromethane Resistance Tester Standards:

- ISO 9852-2007

Dichloromethane Resistance Tester Principle:

A piece of PVC-U pipe, of specified length, chamfered at one end to an angle-dependent on its thickness, is immersed for 30min in dichloromethane, at a temperature specified by the referring standard, to verify that the PVC-U is not attached at that temperature. For safety reasons, the surface area of the dichloromethane is kept to the minimum and the dichloromethane is covered by a deep layer of water to reduce evaporation. After immersion in the dichloromethane, the test piece is held in the water layer to allow it to “drip” before final drying and inspection.

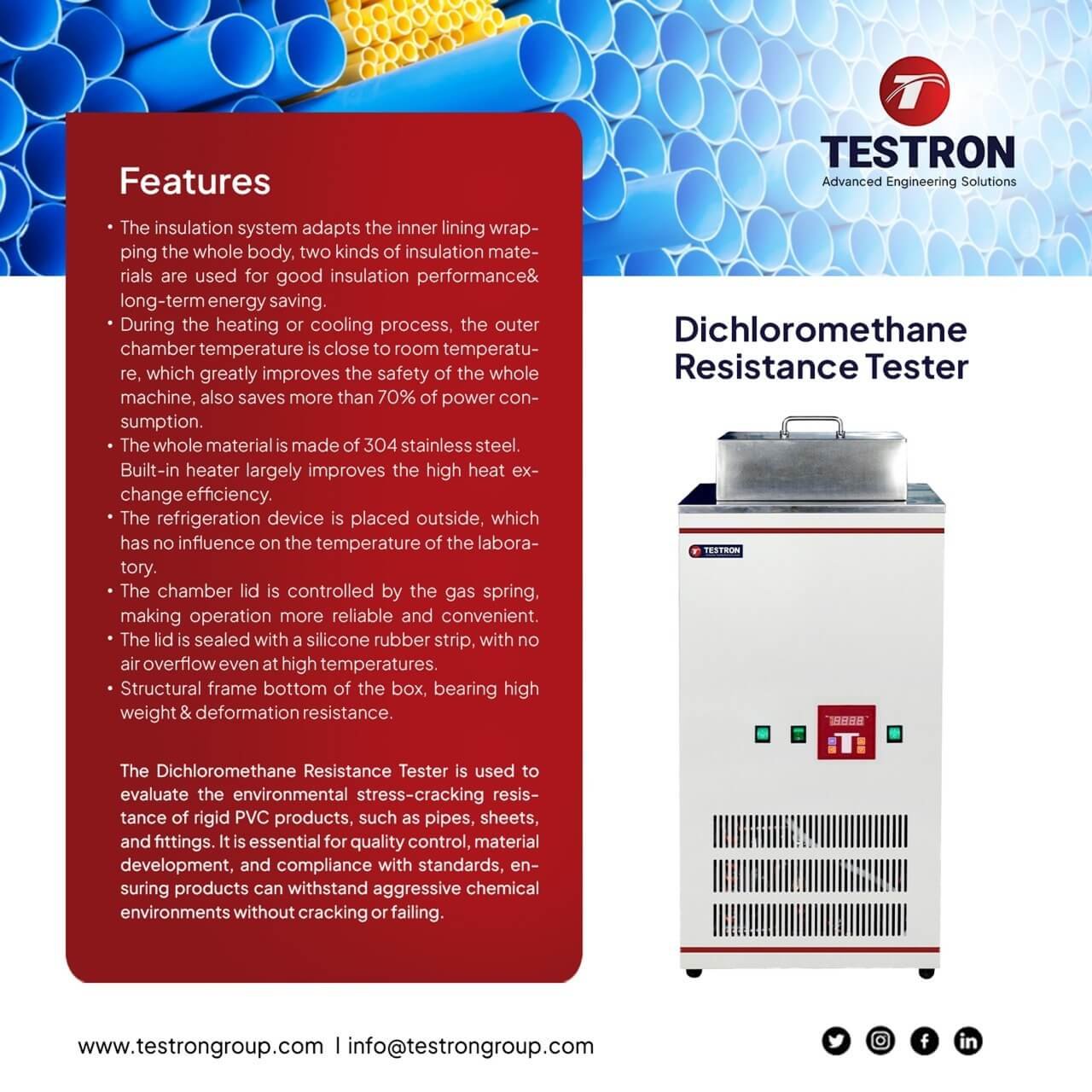

Dichloromethane Resistance Tester Feature:

- The insulation system adapts the inner lining wrapping the whole body, two kinds of insulation materials are used for good insulation performance& long-term energy saving.

- During the heating or cooling process, the outer chamber temperature is close to room temperature, which greatly improves the safety of the whole machine, also saves more than 70% of power consumption.

- The whole material is made of 304 stainless steel.

- Built-in heater largely improves the high heat exchange efficiency.

- The refrigeration device is placed outside, which has no influence on the temperature of the laboratory.

- The chamber lid is controlled by the gas spring, making operation more reliable and convenient. The lid is sealed with a silicone rubber strip, with no air overflow even at high temperatures.

- Structural frame bottom of the box, bearing high weight & deformation resistance.

Dichloromethane Resistance Tester Technical Parameters:

- Temperature range: 10℃~50℃ (With cooling and heating devices)

- Temperature uniformity: ±0.5℃

- Temperature resolution: 0.1℃

- Test medium: pure water

- Test bath dimension: φ350mm x 260mm

- Overall dimension: 660×660×800(mm)

- Power supply: 220VAC,50Hz,3kW

Dichloromethane Resistance Tester Associated equipment:

- Ventilation Chamber