Thermal Shock test chambers are designed to give quick transitions between a HOT and COLD temperature zones.

Why thermal shock test is done?

Thermal shock testing is performed to help determine the ability of components/specimen to withstand rapid changes in temperature, due to the extremely high rate of change of temperature, it is considered to be a severe test.

Thermal stock test chambers are used in a variety of industries, including automotive, electronics, aerospace, and others, to assist in the detection of product flaws in electronic components and assemblies.

2-Zone Thermal Shock Test Chamber

2-zone hot cold thermal shock test chamber is available in small capacity and large capacity to meet different testing requirements. The specimen is automatically transferred from the cold chamber to the hot chamber by the basket. The basket slides vertically and smoothly through rails, to make the specimen is exposed to the two chambers.

The thermal shock test chamber has upgraded to a touch-screen controller with Ethernet, you are easy to operate over the network.

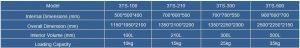

Models:

3TS Series Thermal Shock Test Chamber

3TS series thermal shock test chamber, it is just one chamber for the test room, it circulates cold and hot air through the pneumatic damper on the left and right sides. This design makes the external size smaller, and this 3TS series thermal shock chamber is pre-heated and pre-cooled to achieve faster test temperature.

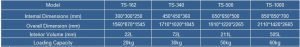

3TS series thermal shock chamber can pre-record the programs so that customers can start test only click program numbers. Standard and custom models meet different requirements.

Models: