UV WEATHERING RESISTANCE TEST CHAMBER – PRECISION TESTING FOR LONG-TERM MATERIAL DURABILITY

In today’s competitive manufacturing landscape, product longevity and performance under harsh environmental conditions are more important than ever. The UV Weathering Resistance Test Chamber is an essential instrument for industries aiming to evaluate how materials perform when exposed to sunlight, rain, humidity, and temperature variations. This UV weathering test chamber simulates natural outdoor conditions within a controlled laboratory setup, providing accurate and repeatable results that help predict a product’s long-term durability.

At Testron Group, we manufacture advanced UV weathering chambers designed to deliver superior accuracy and reliability for a wide range of testing requirements. Our UV test chambers integrate cutting-edge UV lamps, intelligent controllers, and precise humidity regulation systems, making them ideal for accelerated testing of polymers, coatings, paints, plastics, and composites. Whether you are developing automotive components, construction materials, or packaging films, our UV environmental test chambers ensure your materials meet global quality and safety standards.

WHY UV WEATHERING TESTS ARE CRUCIAL IN MODERN MANUFACTURING

Outdoor exposure subjects materials to years of sunlight, temperature fluctuation, and moisture : all of which can lead to fading, cracking, brittleness, or loss of mechanical strength. Traditional real-time testing can take months or years to complete. In contrast, an accelerated UV weathering chamber replicates years of outdoor conditions within days or weeks, providing fast and dependable data for product development and quality assurance.

By using the best UV weathering test chamber, manufacturers can:

- Predict color changes, gloss reduction, and surface chalking in paints or coatings.

- Analyze polymer degradation due to UV and thermal effects.

- Evaluate material resistance to cracking, blistering, and embrittlement.

- Validate product lifespan under specific climate zones.

- Enhance product formulations to improve weatherability and performance.

- Comply with international testing standards such as ISO 4892, ASTM G154, and GM 9125P.

ADVANCED DESIGN AND WORKING PRINCIPLE OF TESTRON’S UV WEATHERING TEST CHAMBER

Testron’s UV weathering test chamber replicates environmental stress through controlled exposure to UV radiation, temperature, humidity, and water spray cycles. It operates on the principle of alternating cycles of light and moisture to simulate dew formation and sunlight exposure :-the two main causes of outdoor degradation.

Our UV Accelerated Weathering Tester uses UVA-340 and UVB-313 fluorescent lamps to mimic the solar spectrum responsible for polymer damage. The chamber ensures uniform light distribution, while the internal sensors continuously monitor irradiance and temperature levels for precise control.

KEY FEATURES OF UV WEATHERING TEST CHAMBER

- Equipped with eight fluorescent UV lamps (UVA-340 or UVB-313) with 40 W output each

- Adjustable black panel temperature (BPT) range from 30°C to 80°C.

- Temperature control range from ambient to +90°C for versatile test conditions.

- Built-in water tank with automatic refill and purification system.

- User-friendly programmable color touchscreen controller.

- Ethernet and USB connectivity for remote monitoring and data export.

- Durable stainless-steel inner chamber with polyurethane thermal insulation.

- Compliance with major global testing standards including ISO, ASTM, and GM.

BENEFITS OF USING TESTRON’S UV WEATHERING CHAMBER

Investing in Testron’s UV weathering test chamber means ensuring reliability, repeatability, and confidence in your product’s performance. Key advantages include:

- Faster product validation and R&D turnaround.

- Enhanced product quality and compliance with global standards.

- Reduced warranty claims due to pre-tested durability.

- Improved market competitiveness through superior weather-resistant products.

- Energy-efficient operation and low maintenance design.

- Real-time data tracking and remote accessibility via Ethernet and USB integration

MODEL OVERVIEW – TT-UVA260 UV WEATHERING RESISTANCE TEST CHAMBER

Model | Internal Dimensions (mm) | Overall Dimensions (mm) | Temperature Range | Humidity Range | Lamp Type | Specimen Capacity |

TT-UVA260 | 450×1170×500 | 680×1300×1500 | Ambient to +90°C ±2°C | ≥95% RH | Fluorescent UV (8×40W) | 56 Pieces |

This model ensures superior testing accuracy and uniform exposure with adjustable parameters. It supports programmable control cycles, including light, condensation, and spray, to mimic real-world aging conditions effectively.

APPLICATIONS OF UV WEATHERING TEST CHAMBER

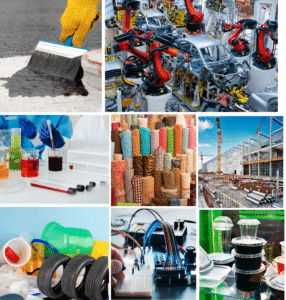

The UV weathering test chamber is used across multiple industries to ensure materials retain their performance, color, and strength when exposed to outdoor conditions. Common applications include:

- Automotive Industry: Testing paints, plastics, and interior trims for UV resistance and fading.

- Construction Materials: Evaluating roofing, sealants, and façade coatings for long-term durability.

- Packaging Industry: Ensuring polymer films and labels retain clarity and print quality.

- Aerospace Components: Assessing composite strength and coating adhesion under UV radiation.

- Electronics: Checking casing materials for discoloration or brittleness over time.

- Textile and Leather: Determining colorfastness and material degradation due to sunlight.

- Fluorescent UV Lamps – 40 W (UVA or UVB type).

- Stainless-steel sample holders (75×150 mm).

- Nichrome heating element for rapid temperature recovery.

- Integrated air circulation fan for uniform thermal distribution.

- Additional safety features like over-current, water shortage, and leakage protection.

- High-efficiency water purification and filtration system.

- Calibration certificate as per ISO 17025 standards.

When selecting a UV weathering test chamber, consider the following aspects to ensure optimal testing performance:

- Lamp Type: Choose UVA-340 for sunlight simulation or UVB-313 for accelerated degradation.

- Temperature Control: Ensure wide range and stability for varied testing conditions.

- Irradiance Uniformity: Consistent UV distribution ensures repeatable results.

- Programmability: Advanced controllers reduce manual intervention.

- Compliance: Verify that your chamber meets ASTM, ISO, and GM standards.

- Chamber Size: Select based on your specimen dimensions and batch size.

- After-Sales Support: Opt for manufacturers offering calibration, servicing, and spare parts.

WHY CHOOSE TESTRON GROUP AS YOUR UV WEATHERING TEST CHAMBER MANUFACTURER

As a trusted UV weathering test chamber manufacturer and supplier, Testron Group combines engineering excellence with innovation. Our equipment is designed and tested under strict quality control to deliver dependable performance in every use.

We provide complete customer support—from consultation and customization to installation and calibration. Our UV test chambers are used in reputed testing labs, research institutions, and industrial quality control departments globally.

Whether you are looking for a UV test chamber for routine tests or an accelerated UV weathering chamber for advanced research, Testron ensures value, accuracy, and reliability.

UV WEATHERING RESISTANCE TEST CHAMBER FREQUENTLY ASKED QUESTIONS

It is used to simulate natural weathering conditions like sunlight, humidity, and temperature to evaluate how materials age over time.

Testing duration depends on the desired exposure level. Accelerated tests usually last from a few days to several weeks.

Paints, coatings, plastics, rubber, fabrics, composites, and packaging materials can all be evaluated for UV resistance and color stability.

Both models support USB data logging; TT‑DSC300 can export Excel and PDF reports and connect via USB or Ethernet to LIMS systems.

It complies with ISO 4892, ASTM G154, ASTM D4329, and several automotive and construction material standards.

The UV test chamber price varies depending on model, features, and customization options. Contact Testron Group for a competitive quote tailored to your requirements.