In the field of material testing, impact strength plays a crucial role in determining the durability and reliability of materials under sudden load or stress. Among the most widely recognized testing solutions, the Charpy impact tester stands out as a standardized instrument for evaluating the resilience of plastics , metals, pipes, composites, and other rigid materials.

The Charpy impact test machine works on a simple yet highly effective principle , measuring the energy absorbed by a specimen when struck by a pendulum hammer at a defined velocity. This reveals the impact fragility characteristics of a material, ensuring manufacturers can guarantee the safety, reliability , and performance of their products.

At Testron Group, we offer advanced Charpy impact testing machines engineered with precision, accuracy , and compliance with international standards like ISO 179. Our range is trusted by industries worldwide, from plastics and polymers to automotive and construction, making us one of the best Charpy impact tester manufacturers.

Whether you are searching for an affordable Charpy impact tester price, a high performance Charpy impact test apparatus, or a customized Charpy impact tester machine, Testron has the right solution tailored to your needs.

WHAT IS A CHARPY IMPACT TESTER?

A Charpy impact tester machine is a laboratory instrument designed to perform impact resistance tests by striking a notched specimen with a pendulum at a set speed. The energy absorbed by the specimen is measured, providing valuable data on toughness, brittleness, and ductility.

KEY FUNCTIONS OF CHARPY IMPACT TESTER

- Measures material toughness under dynamic loading

- Determines the brittle to ductile transition temperature of materials and assesses quality and safety compliance for industrial use

This test is widely used across multiple industries where safety and durability are non negotiable factors.

STANDARDS FOR CHARPY IMPACT TEST MACHINES:

Our Charpy impact testing machines comply with globally recognized standards, ensuring credibility and repeatability.

- ISO 179 Part 1 :- Plastics impact resistance ( non instrumented test )

- ASTM D6110 :- Standard test for plastics impact testing

- EN ISO 148-1 :- Metals Charpy V notch impact test

With these standards, Testron ensures that every Charpy impact testing machine delivers results that meet global testing norms.

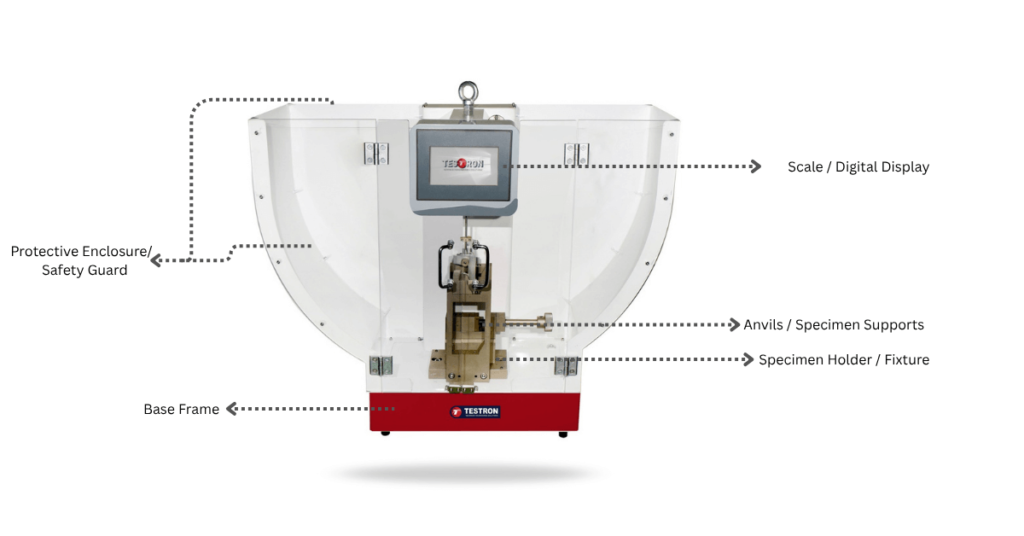

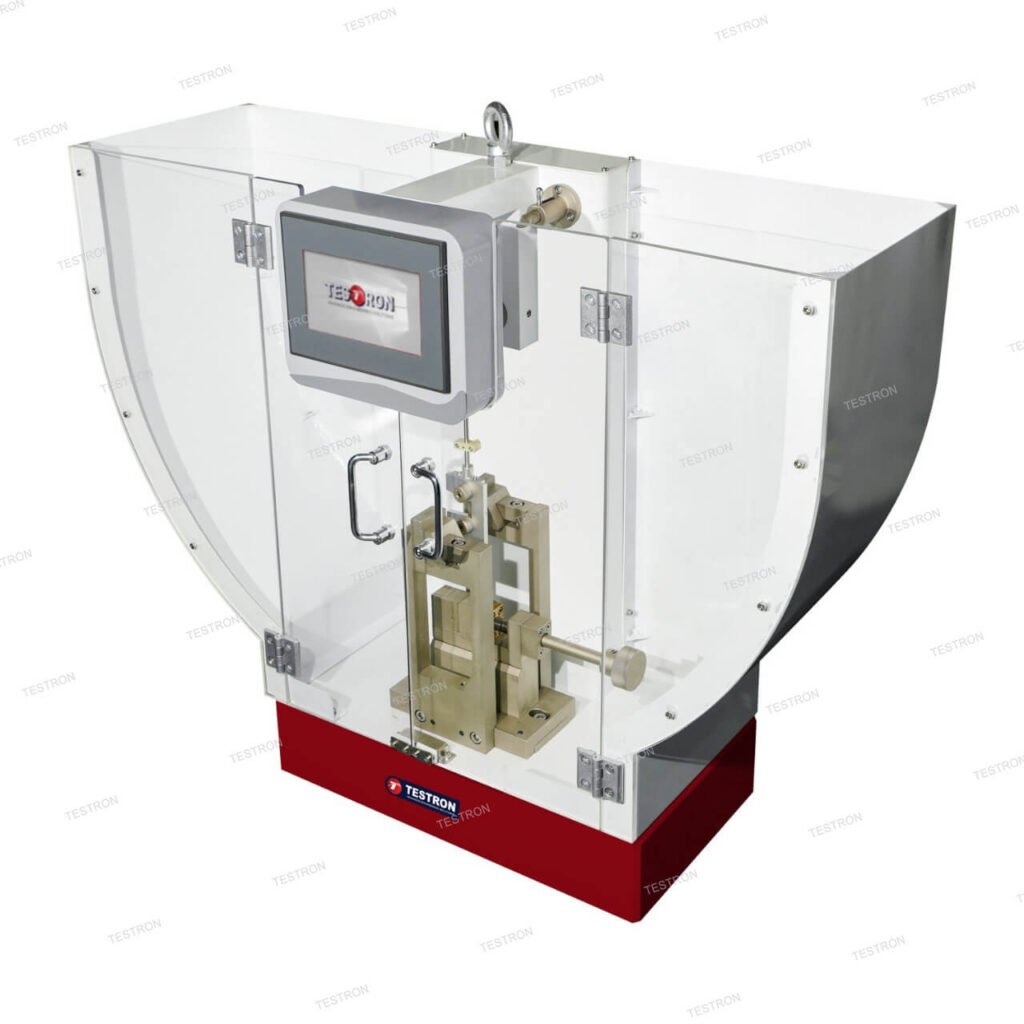

Our Charpy impact test equipment is designed with cutting edge features for maximum accuracy and ease of use:

- High precision pendulum system with minimal energy loss

- Multiple impact energy levels ( 1J to 50J ) for flexible testing

- Touchscreen control panel for quick parameter input

- Automatic correction for friction and air resistance losses

- Encoder based measurement system for accurate readings

- Strong safety enclosures for operator protection

These advanced features make Testron’s Charpy impact tester machines one of the best Charpy impact testers available today.

Our Charpy impact test machines are available in two major models ( CIT-5 and CIT-50 ), each tailored to different testing requirements.

- Energy Capacity: 1J, 2J, 4J, 5J ( CIT-5 ) / 15J, 25J, 50J ( CIT-50 )

- Impact Speed: 2.9 m/s ( CIT-5 ) / 3.8 m/s ( CIT-50 )

- Span of Charpy: 62 mm

- Resolution: 0.01 J

- Notch Types: A, B, C with standard radii

Investing in a high quality Charpy impact test apparatus offers multiple benefits:

- Accurate material characterization under stress conditions

- Enhanced safety compliance with ISO and ASTM standards

- Cost savings by preventing premature failures and recalls

- Reliable R&D data for innovation in material development and versatility for testing different materials and thicknesses

APPLICATIONS OF CHARPY IMPACT TESTING MACHINE

The Charpy impact tester is indispensable across industries where structural integrity is critical:

Plastic Industry

Evaluating polymer toughness for packaging, pipes, and automotive parts

Metals & Alloys

Testing brittle vs ductile behavior in steel and aluminum.

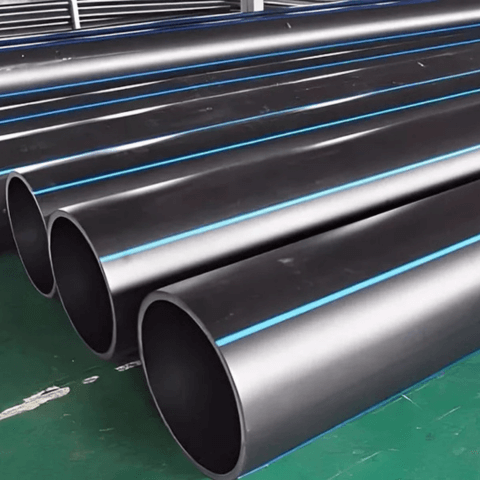

Pipes

Measuring resistance to sudden breakage under pressure

Tubes

Assessing resistance to sudden breakage when subjected to pressure.

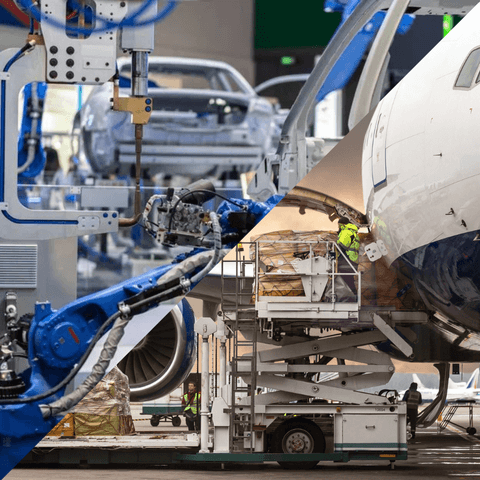

Automotive & Aerospace

Assessing crash resistance and safety compliance

Construction Materials

Ensuring concrete and composites can withstand impact stress

HOW DOES A CHARPY IMPACT TESTER MACHINE WORK?

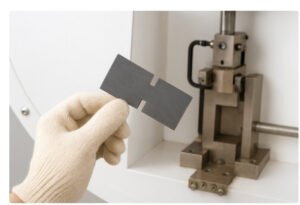

- Sample Preparation :- A notched specimen is cut to standard dimensions.

- Positioning :- The specimen is supported as a horizontal beam.

- Impact :- A pendulum striker hits the specimen at high speed.

- Energy Measurement :- The absorbed energy is calculated.

- Result Analysis :- Data reveals whether the material is brittle or ductile.

This simple yet effective procedure makes the Charpy impact test machine an essential instrument in every material testing laboratory.

CHOOSING THE BEST CHARPY IMPACT TEST EQUIPMENT

When evaluating Charpy impact tester price and models, consider the following factors:

- Testing standards required ( ISO, ASTM, EN )

- Maximum energy levels needed for your samples

- Material types ( plastic, metal, composites )

- Ease of operation and automation features and After sales service and calibration support

At Testron Group, we provide complete consultation and support to help you choose the best charpy impact tester for your application.

MAINTENANCE & CALIBRATION TIPS

To ensure long term accuracy of your Charpy impact test equipment, regular care is essential:

- Perform routine calibration to maintain accuracy

- Inspect pendulum alignment before each test

- Lubricate mechanical parts for smooth functioning

- Replace worn out notches or anvils

- Keep software/firmware updated in digital models

INDUSTRIES THAT RELY ON CHARPY IMPACT TESTING

- Plastics & Polymers

- Metals & Alloys

- Aerospace & Aviation

- Automotive Manufacturing

- onstruction & Infrastructure

- Pipe & Tube Production

- Research & Academic Institutions

COMPARATIVE TABLE: CIT-5 VS CIT-50

| Feature | CIT-5 Model | CIT-50 Model |

| Max Energy Capacity | 5J | 50J |

| Impact Speed | 2.9 m/s | 3.8 m/s |

| Application | Plastics, light materials | Metals, composites |

| Resolution | 0.01 J | 0.01 J |

| Industries | Packaging, pipes, R&D labs | Automotive, aerospace, construction |

CHARPY IMPACT TESTING MACHINE FREQUENTLY ASKED QUESTIONS

A Charpy impact tester is used to measure the toughness and impact resistance of materials under sudden loading conditions.

Charpy supports the specimen horizontally, while Izod holds it vertically. Both measure impact toughness, but in different configurations.

Testron provides ISO certified, high precision Charpy impact testers, backed by global support, making us one of the best Charpy impact tester manufacturers.

Yes, with the correct model ( CIT-5 for plastics and CIT-50 for metals ), it can test both material categories.

The Charpy impact test machine price varies depending on model capacity, automation, and brand. Testron offers competitive pricing with high accuracy.

Calibration is recommended every 6:-12 months or as per industry standards.