In materials testing, precision matters. Engineers and QC specialists across the USA rely heavily on Charpy impact test equipment to evaluate toughness, durability, and fracture resistance. As lab demands grow, only the most advanced Charpy impact tester, testing machines, and instruments can deliver reliable results and efficient operation.

This comprehensive 1,500‑word blog explores top tier Charpy impact testing equipment, outlines key purchasing factors, and showcases how these devices enhance materials testing across industries. For industrial specialists and lab managers considering a new Charpy impact test machine investment, here’s your definitive guide.

Why Charpy Testing Remains a Cornerstone in Materials Science

First standardized in the early 20th century, Charpy impact test apparatuses continue to give essential insights into how materials behave under sudden stress. Whether you work in aerospace, automotive, or advanced plastics, your ability to measure resilience fast is crucial.

Here’s what makes modern Charpy impact test devices indispensable:-

- Compliance with global standards, including ISO 179 and ASTM methods.

- Quick and repeatable results, helping labs run more samples in less time.

- Data driven precision, with digital measurement reducing human error.

Anatomy of a Leading Charpy Impact Tester:- What to Look For

Not all units labeled Charpy impact testing machines in the USA are created equal. Here’s what sets the best apart:-

- Pendulum Design & Energy Ratings

A robust pendulum ensures consistent performance across multiple energy ranges. The popular dual speed options—such as 2.9 m/s and 3.8 m/s—let you accurately test materials from 1 J to 50 J. - Striker & Notching Precision

Widely used models, like the CIT‑5 (1–5 J) and CIT‑50 (15–50 J), use high fidelity pendulums and sharp notch radii, upholding Charpy impact test equipment standards. - Digital Encoder + Touch Interface

Built in high resolution encoders and touch screen controls streamline operations while improving repeatability in each drop. - Auto‑Correction Functions

To ensure accuracy, the system adjusts for friction and air resistance—crucial in modern Charpy test instruments. - Data Logging & Reporting

QC labs demand traceable output. Leading Charpy impact test machines include USB or Ethernet connectivity for seamless LIMS integration.

Top Charpy Impact Tester in the USA — Full Features Spotlight

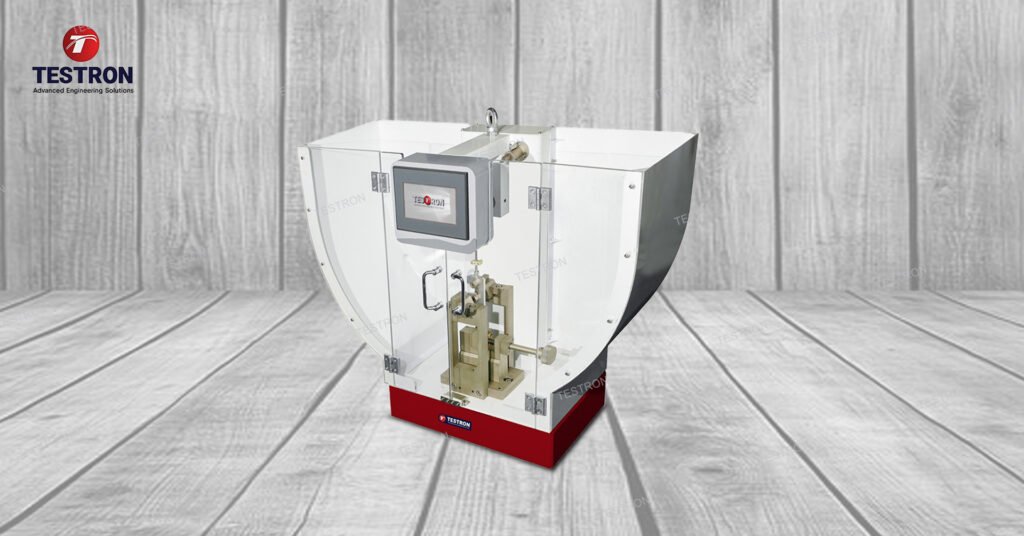

Introducing the latest precision Charpy pendulum impact tester, designed to tackle rugged materials and demanding workload:-

- Meets ISO 179 Part 1 for non instrumented impact testing

- Dual strike energy levels (2.9/3.8 m/s) supporting 1–50 J operations

- Heavy pendulum to minimize vibration and energy loss

- High resolution encoder, ±0.01 J accuracy

- Touch panel for setting specimen support span and monitoring

- Auto energy correction and built in micro printer

- Easy integration with existing lab workflows

Read more: Explore the Power of the Izod Impact Testing Machine for Quality Assurance

Investing in the Right Equipment:- What QC Directors Should Know

From Charpy impact test equipment price to lab compatibility, here are key decision points:-

- Pricing vs. Versatility

A robust Charpy impact test machine may exceed basic models’ cost, but combining multiple features offers better ROI. - Support & Maintenance

Reliable training, calibration, and spare parts access is essential—look for vendors with proven lab partnerships. - Compliance & Standardization

Ensure your device aligns with ISO 179, ASTM, and local industry specifications. - Scalability & Upgradability

Digital models can evolve through software—offering future resilience and workflow integration.

Streamlining Lab Operations with Charpy Testing Equipment in the USA

In high throughput labs, every second counts:-

- Modular specimen setup allows rapid notching and loading

- Automated calibration functions reduce downtime

- Digital recording and printing simplify quality assurance

- Safety mechanisms, such as enclosed pendulum chambers, safeguard technicians

Real World Applications

- Automotive Suppliers:- Testing polymer ductility under sudden impact.

- Construction & Infrastructure:- Verifying toughness of rigid plastics and composites.

- Aerospace Supply Chains:- Ensuring consistent performance across enviro stresses.

- Educational Institutions:- Teaching impact theory with high accuracy, safe equipment.

Comparing Leading USA Charpy Machines — Table Overview

Feature | Standard Bench Tester | Advanced Digital Model |

| Energy Range | Fixed (1–5 J) / (15–50 J) | Dual range (1–50 J) selectable |

| Notch & Pendulum Quality | Standard carbon steel | Machined high mass pendulum |

| Data Capture | Manual | Auto logging, printer, export |

| Standard Compliance | ISO 179, ASTM D256 | Includes ISO/JIS standards support |

| Integration & Upgrades | Minimal | Ethernet/USB support, remote updates |

Field Comparison:- Why the New Tester Wins

- Higher throughput:- Touch interface and auto calibration speed specimen cycles

- Cost efficiency:- Less retraining and fewer operation errors saves time

- Reliability:- Enhanced components reduce recalibration frequency

Integrating Into Existing Lab Infrastructure

Ensure smooth implementation with:-

- Lab Survey & Integration Plan – Map space, power, and data needs

- Staff Training – Cover operation, calibration, and sample prep

- Software Compatibility – Enable LIMS and SPC linkages

- Maintenance Schedules – Prevent drift through planned checks

- Calibration Protocols – Align with ISO/ASTM calibration standards

Setting New Industry Standards in 2025

As materials science moves toward composites and recycled polymers, Pipe testing equipment called Charpy impact test apparatuses have been upgraded with:-

- Enhanced digital integration

- Flexible energy range for new material formats

- Modular support for future proof expansion

This renders labs agile, cost effective, and ready for next gen materials.

Optimizing Test Workflows with Digital Charpy Equipment

In modern laboratories, efficiency is paramount. Industry leading Charpy impact testing machines offer clean, optimized testing workflows:-

- One button procedures enable reproducible workflows and reduce training time.

- Data consistency ensures reliability for ISO 9001 and client audits.

- Maintenance alerts—such as for pendulum calibration—are automated, reducing manual checks.

- Integration with SPC systems helps manufacturers maintain process control and root‑cause analysis after failures.

- Remote diagnostics allow service teams to assess and resolve issues on site with minimal disruption.

Adopting such digitally enabled Charpy impact test machines empowers labs to scale operations, enhance data quality, and maintain compliance effortlessly.

Final Takeaway

For labs serious about material toughness testing, the Charpy impact testing equipment featured here represents the best in performance, flexibility, and compliance. As engineering demands evolve and materials become more complex, your choice in testing gear can make or break QA programs and R&D insights.

In 2025, the next generation Charpy impact test machines—with digital precision, configurable energy ranges, and robust data pipelines—aren’t just equipment. They’re essential tools for innovation.

Related: Explore the Next Generation of Izod & Charpy Testing in One Machine

FAQs About Charpy Impact Test Equipment

Advanced units offer ±0.01 J accuracy and apply digital corrections to eliminate operator bias.

Entry level machines start around mid range pricing, while feature rich Charpy impact test machines typically fall into mid to upper tier budgets based on energy options and digital tradeoffs.

Automotive, aerospace, consumer goods, construction materials, and educational research labs use it for compliance with impact standards.

Focus on energy requirements (5J vs. 50J), data needs (printer/export), standard compliance, and vendor support reputation.