Structural advantages of TT-TGA1550 Thermogravimetric Analyzer

- Furnace body heating adopts precious metal alloy wire double row winding system, which reduces interference and is more resistant to high temperature.

- Tray sensors, made of precious metal alloy plate, have the advantages of high temperature resistance, oxidation resistance and corrosion resistance.

- The power supply and circulating cooling parts are separated from the main engine to reduce the influence of heat and vibration on the microbalance.

- It is easy to operate and has a tail gas output port, which is easy to expand and connect infrared equipment.

- The thermal insulation of the main unit and the case of the balance are affected by the thermal insulation.

- The furnace body adopts double heat preservation, with better linearity.

Advantages of controller and software of TT-TGA1550 Thermogravimetric Analyzer

- Using imported ARM processors, sampling speed, and processing speed is faster.

- Four channel sampling ads are used to collect TG signal and temperature T signal.

- Heating control, using PID algorithm, precise control. Can be multi-stage heating, constant temperature

- USB two-way communication is adopted between the software and the instrument to realize remote operation completely. The parameter setting and operation stop of the instrument can be realized by computer software.

- 7-inch full color 24bit touch screen, better man-machine interface.TG calibration can be achieved on the touch screen.

Application of TT-TGA1550 Thermogravimetric Analyzer

- Thermogravimetric analyzer is widely used in research and development, process optimization and quality monitoring in various fields such as plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composite materials.

Technical Specifications of TT-TGA1550 Thermogravimetric Analyzer

| Model | TT-TGA1550 |

| Temperature range | Room Temperature ~ 1550 ℃ |

| Temperature resolution | 0.01 ℃ |

| Temperature fluctuation | ± 0.1 ℃ |

| Heating rate | 0.1 ~ 100 ℃ / min |

| Temperature control mode | PID Control, heating, constant temperature and cooling |

| Program control | Program setting multi-stage temperature rise and constant temperature, five sections can be set at the same time |

| The measuring range of the balance | 0.01mg ~ 3g, which can be extended to 50g |

| Precision | 0.01mg |

| Constant temperature time | Arbitrary setting |

| Resolution | 0.1ug |

| Display mode | 7-inch Chinese character large screen LCD display Built in gas flow meter and gas flow control device |

| Software | intelligent software can automatically record TG curve for data processing, TG / DTG, mass, percentage coordinates can be arbitrarily switched; Software with automatic adjustment function, according to the map display, automatic extension, scaling |

| The gas path can be set with multi-stage automatic switching without manual adjustment | |

| Data interface | standard USB interface, special software (software upgrade for free from time to time) |

| Power Supply | AC220 V, 50 Hz |

| Curve scanning | heating scanning and cooling scanning |

| Five test maps can be opened at the same time for comparative analysis | |

| Cooling time | ≤ 15min, 1000 ℃ ~ room temperature; Air cooled cooling device is selected to reduce temperature quickly and improve test efficiency |

| Crucible type | ceramic crucible, aluminum crucible |

| Crucible size | 5 * 5mm, 7.5*7.5mm |

| Standard substance | one copy |

Standard Configuration of TT-TGA1550 Thermogravimetric Analyzer

| Serial | Accessories | Qty | Remarks |

| 1 | Main unit | 1 | |

| 2 | USB Drive | 1 | |

| 3 | Data Line | 2 | |

| 4 | Power cord | 1 | |

| 5 | Ceramic crucible | 200 | |

| 6 | Ceramic Cover | 2 | |

| 7 | Metal Cover | 1 | |

| 8 | Raw Tape | 1 volume | |

| 9 | Standard Tin | 1 bag | |

| 10 | 10A fuse | Five | |

| 11 | Sample Spoon / pressure bar / forceps | 1 for each | |

| 12 | Dust Cleaning ball | 1 | |

| 13 | Trachea | 2 | Φ8mm |

| 14 | Operation manual | 1 | |

| 15 | Warranty card | 1 | |

| 16 | Quality certificate | 1 |

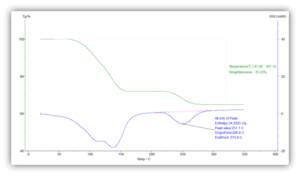

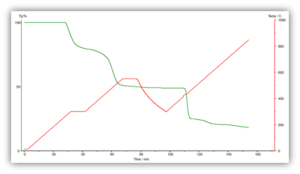

Part of the test spectrum of TT-TGA1550 Thermogravimetric Analyzer