- Trusted thermogravimetric analyzer machine designer and supplier, with global QA compliance history.

- Responsive U.S. based support and annual calibration services ensure reliability.

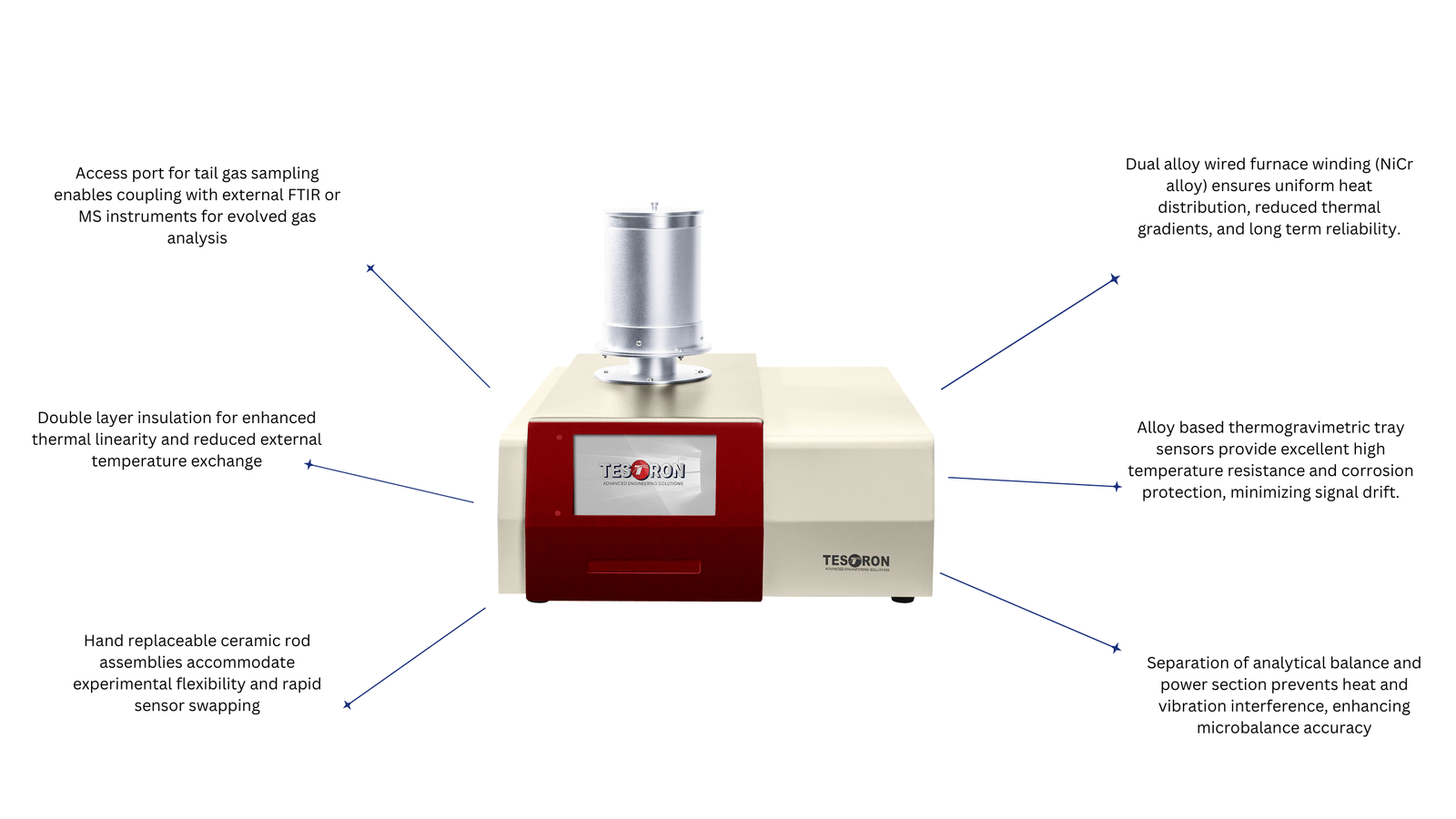

- Custom configurations such as infrared coupling and autosampler interfaces available.

- Transparent pricing , no hidden accessory costs , so the thermogravimetric analysis cost can be planned effectively.

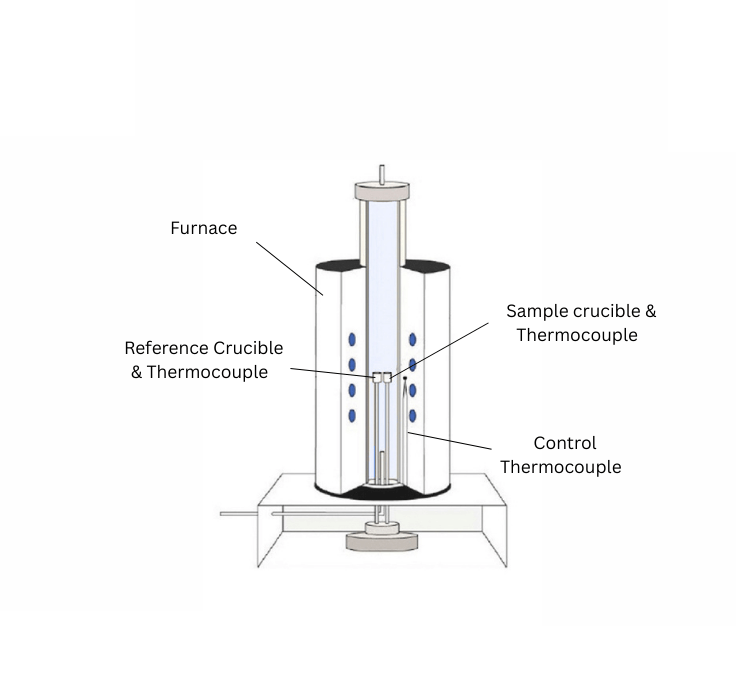

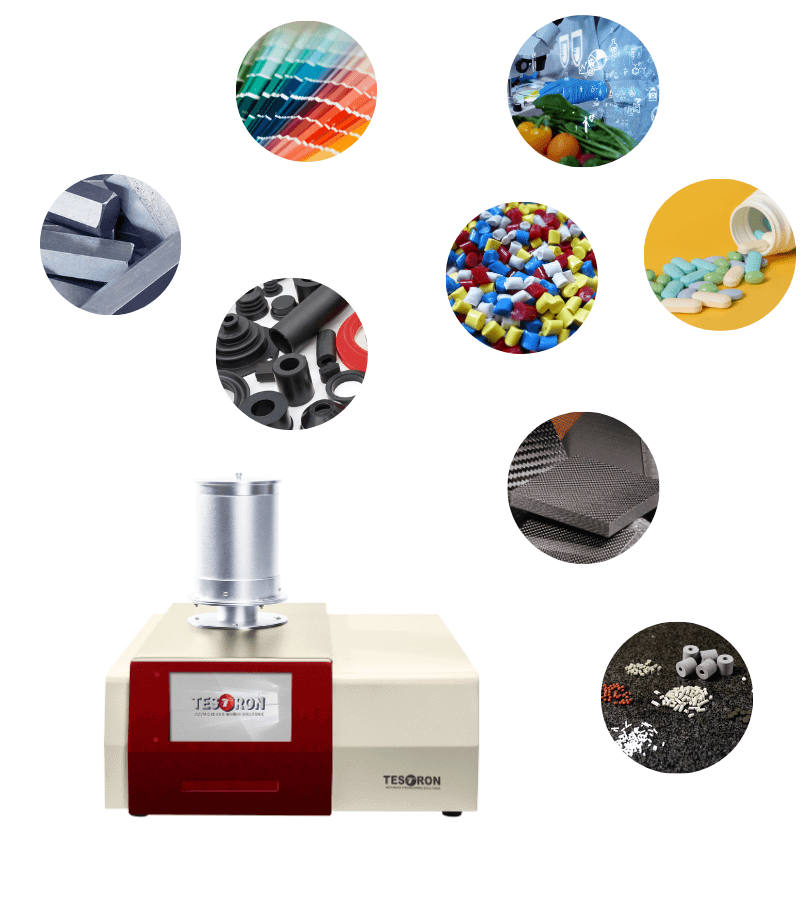

Thermogravimetric Analyzer