Introduction: Importance of Surface Roughness Tester Calibration in Indonesia

The rapid adaptation of metal testing technology has helped many industries and manufacturing units in Indonesia. In this race, the importance of a surface roughness tester in Indonesia is on the rise. However, industrial buyers of these tools should be aware of those technical details and conduct necessary calibration for smoother and longer operations without any interruption.

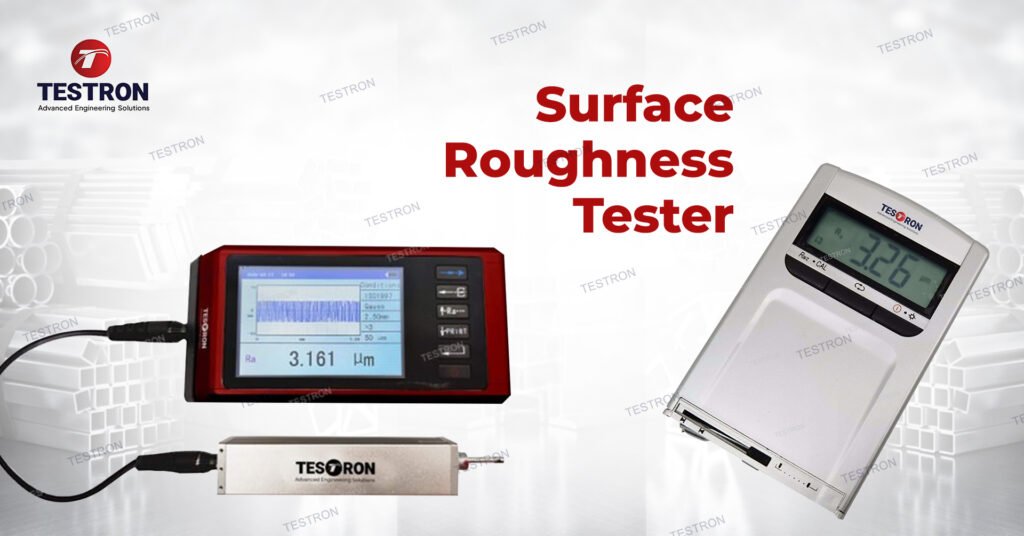

The device – surface roughness tester in Indonesia – is the best choice for metal testing. It yields various productive properties, helping the operators to measure the surface finish of the metals.

In metal testing, the name of Testron’s surface roughness tester in Indonesia is famous. When it comes to providing requisite calibration, the technicians always provide the right aid at the right time without interrupting any delay in the production, metal testing, and other lab-related workloads.

Emphasize the edge that proper calibration provides—secure your company’s reputation and compliance by enforcing routine calibration practices for all surface roughness tester machines.

Get A Small Brief on Surface Roughness Tester for Metals?

A Surface Roughness Tester machine carries a lot of impact in metal testing. When it is used properly, the device can provide the best results in terms of producing mass metal products with flawless designs.

There are advanced portable surface roughness testers designed by Testron, which are designed to find microscopic valleys and peaks on the metal surfaces without any delay.

These Surface Roughness Tester machines are available in analogue and digital types. They can

- Measurement range: such as Ra, Rz, Rt, etc, based on the device.

- Demand is high among industries like automotive and aerospace.

- Predict various attributes earlier, such as wear, friction, assembly fit, and adhesion of paint.

Also, there are many industrial uses of each surface roughness tester in Indonesia. However, it is important to conduct a frequent and valid surface roughness tester calibration.

When the operators fail to conduct the surface roughness tester calibration on time, they might face certain issues later. So, it is better to do the calibration on time with the premium tech support from Testron.

Availability of Testron Group’s Surface Roughness Testers in Indonesia

The technological upgrades have played a huge role in evolving different types of impact testers. Previously, operators were relying more on an analogue surface roughness tester. However, the time has changed a lot due to the arrival of the latest and feature-rich metal surface testing devices.

The engineers from the Testron group have designed each surface roughness tester in Indonesia to fulfill the requirements of the industries, labs, and manufacturing sites. Here is the list:

1. Digital Surface Roughness Testers

Available models from Testron:

Noticeable Features:

- Comes with a separate driver.

- Multi-parameter measuring range.

- USB interface with a big display.

2. Handled Surface Roughness Testers

- Testron’s Model: TT-3110 (TR110)

Noticeable Features:

- Pocket-sized unit.

- Measuring range: Ra and Rz.

- Economical surface roughness tester price.

- Confirms to ISO and DIN.

3. Analogue Surface Roughness Tester

- Available models from Testron: TT-A202 measuring platform

- Noticeable Features: Small, compact design, easy to carry, and appropriate for roughness testing on multiple surfaces.

These Portable Surface Roughness Testers are the game-changing devices in the metal testing sector. Based on the right type of surface roughness tester you choose will impact your operations, accuracy, and calibration frequency.

Get in touch with Testron Group’s experts—schedule demonstrations, consultation sessions, or maintenance packages tailored for Indonesian industry needs.

Impact of the Calibration of Surface Roughness Tester in Indonesia

The need to conduct the calibration for a surface roughness tester in Indonesia is important. When you ignore or fail to do the regular calibration, this may not cause damage earlier. However, the result will not provide the best deal for long-term negligence.

At the right time, the calibration of a surface roughness tester in Indonesia can fix:

- Avoid the risk of an expensive breakdown.

- Stop measurement drift due to daily operational stresses.

- Counter environmental challenges.

- Stay away from the wear and tear of the tool.

- Smooth supply chain interaction

When operators do the calibration frequently, there will be accurate results without any failure.

Steps to Follow for A Smooth Calibration of a Surface Roughness Tester in Indonesia

This is the basic guide that will help our buyers perform the necessary calibration of a surface roughness tester in Indonesia without any delay.

Follow the recommended Surface roughness tester calibration procedures:

- Clean the tester properly to avoid unnecessary contamination.

- Stylus and probe cleaning is recommended.

- Do keep a certified specimen (reference) whose roughness value should be known earlier.

- Follow the manufacturing guidelines and turn the reading of the instrument to zero.

- Run the device to do measurement of the reference sample.

- Now, you can compare the reading with the reference value.

- If the reading matches the reference, then it’s fine.

- If the value stays above or below the limit, repeat the calibration.

Professional Tip:

Technicians always recommend that you keep all the documents of the calibration processes. Details like date, operator’s name, sample metal data, and others matter the most. This can help you later to build the audit trail appropriate for internal quality controls and external regulatory compliance.

Read more: Explore Trusted Hardness Testers Designed for Accurate Metal Testing

Calibration Standards: What Does Your Tester Need?

Before buying the device, operators should understand whether the products are certified with the Surface roughness tester calibration standards. This aspect is non-negotiable as it gives you the ability to perform globally acceptable metal testing.

- Calibration Standards: ISO, ANSI, DIN, and JIS matter the most.

- Industries that are more into export-oriented manufacturing should focus on buying a reliable and certified Surface Roughness Tester in Indonesia.

- Never forget to check regularly and conduct necessary calibration of your purchase devices.

Learn from our engineers—see how the best leverage calibrated testers for a competitive edge in both local production and export markets.

Engaging with Testron Group: Your Partner for Calibration Solutions

When you buy from Testron, you shake hands with its premium after-sales benefits in Indonesia. At Testron, we provide:

Offer a wide range of roughness testers and calibration specimens.

- Local support and training sessions.

- Maintain transparency on the surface roughness tester price.

- Assist in the necessary calibration on time.

- Provide the latest calibration protocols.

- Advanced tech support.

Conclusion

The cornerstone of smooth metal testing lies with the calibration of a surface roughness tester in Indonesia. With this, an industry can summon growth, accuracy, a high flow of customers, and build strong relations with its industrial partners.

It is time to produce metal products with consistency and meet all the international expectations. Proper calibration ties together every step in the quality control cycle.

Think strategically about your needs—evaluate which tester best supports your workflow, calibration schedule, and productivity goals for superior measurement outcomes. Inquiry at info@testrongroup.com

Related: The Best Surface Roughness Testers for Aerospace, Automotive, and Metal Industries

FAQs About Surface Roughness Testers in Indonesia

– Understand your measurement requirements and technical demands

– Check for calibration support, and your industry’s when selecting a tester.

– Assess prices, support, and warranty terms

– Ensure both functionality and long-term serviceability.

In Indonesia, buying from Testron can aid every need of yours on time.

– Digital versus analog features,

– Measurement range,

– Automation level,

– Accessories, and

– Brand reputation.

Go with Testron’s premium testers as we provide better affordability, durability, and service coverage on our surface roughness testers in Indonesia.