Application of TT-WVTR1000 Water Vapor Permeability Analyzer

It is suitable for the water vapor transmission performance test of films, sheets, paper, packaging, and related materials in the fields of food, medicine, medical equipment, daily chemicals, photovoltaic electronics, etc. It provides high, medium, and low water vapor barrier materials Wide-range, high-efficiency water vapor transmission rate detection.

Test Standard of TT-WVTR1000 Water Vapor Permeability Analyzer

ASTM E96/E96M, ASTM D1653, TAPPI T464, ISO 2528, DIN 53122-1, JIS Z0208, YBB 00092003, GB/T 1037, GB/T 16928

Features of TT-WVTR1000 Water Vapor Permeability Analyzer

- High precision load cell

Equipped with a high-precision weighing sensor, with high weighing efficiency, stable performance, high precision, and a resolution of 0.0001 g/(m2·24h).

- Precise control of temperature and humidity

Electromagnetic program stepping technology accurately controls temperature, imported temperature and humidity sensor, automatic heating and cooling, temperature control accuracy of ± 0.1 ℃, humidity accurate to ± 2%RH.

- Meet the needs of high-throughput, wide range, and high-applicability testing

Equipped with a single chamber, which is small and flexible, and the test efficiency is high.

Measuring range of 0.1~10000 g/(m2·24h), wide range, to meet the test needs of high, medium, and low barrier materials, plus suitable accessories, can measure the water vapor transmission of bottles, bags, bowls, and other containers.

- Excellent shape, convenient control, real-time visualization of curves

With exquisite 3D printed shell, smooth lines, the instrument is fashionable and beautiful.

The instrument is fully automatic operation, one-button test, automatic judgment, automatic shutdown. Real-time display of transmission – time, temperature – time, humidity – time, flow – time four sets of curves, curves support preview hidden function.

- Intelligent operating system, global certification

Self-developed intelligent operating system, modular illustration, fashion color matching, humanized setting, intuitive and convenient operation. According to GMP appendix computer system design, test process parameters are flexibly set to meet different standard requirements.

With the function of audit trail (log trace, test trace) to meet the needs of data traceability. System operation permissions can be set at different levels. Intelligent statistical analysis, support multiple data standard deviation analysis. At the same time, the system can be expanded, such as access to the laboratory LIMS system. Personalized test reports are set on demand, support a variety of formats of data output, support electronic signature function, online submission of audit report function. Global strength certification can be set in Both Chinese and English languages as needed.

- Professional calibration service, accurate and reliable data

Our company has approved and issued by the “General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China”: water vapor transmission rate, “National Standard Material Classification Certificate” and “People’s Republic of China Manufacturing Measuring Instrument License”, the standard number (GBW (E)130543 / GBW(E)130544). The instrument is calibrated and verified by the national standard material independently developed to ensure the accuracy, versatility, and authority of the test data.

- Laboratory intelligent IoT platform

The instrument can be connected to the IoT platform to achieve digital network management.

Remotely log in to the IoT platform and authorize access to the instrument software interface, which can realize functions such as managing experimental data and remotely diagnosing and solving faults. Customers can download the required instrument materials, documents, and operation videos on the platform.

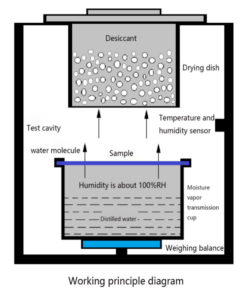

Test Principle of TT-WVTR1000 Water Vapor Permeability Analyzer

Add distilled water to the dry and clean moisture-permeable cup, seal the moisture-permeable cup with a pre-treated sample and place it in the test chamber. By controlling the temperature and humidity, the distilled water in the moisture-permeable cup is evaporated, and the evaporated water vapor passes through the film The drying device absorbs and measures the weight of distilled water in the moisture permeable cup with time to obtain parameters such as the moisture permeability of the sample.

Technical Specification of TT-WVTR1000 Water Vapor Permeability Analyzer

| Model | TT-WVTR1000 |

| Test range | 0.1~10000 g/(m2·24h) |

| Test precision | 0.0001 g/(m2·24h) |

| Temperature range | 15~55℃ |

| Temperature | ±0.1℃ |

| Humidity range | Relative humidity 90%RH |

| Humidity accuracy | ±2%RH |

| Test area | 50.24 cm2 |

| Sample size | Φ90 mm |

| Sample thickness | ≤3mm |

| Number of samples | 1piece |

| Power | 450 W |

| Power supply | AC 220 V,50 Hz |

| Size | 380mm*545mm*315mm |

Standard Configuration of TT-WVTR1000 Water Vapor Permeability Analyzer

| Items | Items |

| Power cord

| Allen wrench |

| Weighing pan | mouse |

| Syringe | 125μm standard film |

| Moisture permeable cup | wire and aviation socket welding components |

| Sampler | Phillips’s screwdriver |

| Sealing grease | standard weight |

| 4A molecular sieve | serial port cable |

| Warranty Card | Instructional Manual |

| Optional | |

| Computer | |