Test Standard of TT-WVTR200 Infrared Method Water Vapor Transmission Rate Tester

ASTM F1249, BS EN ISO 15106-2, JIS K7129, GB/T 26253, YBB 00092003

Features of TT-WVTR200 Infrared Method Water Vapor Transmission Rate Tester

- Patented core technology, efficient and accurate testing

High-precision original imported infrared sensor, high sensitivity, with ultra-high stability and ultra-low failure rate, resolution of 0.0001 g/(m2·24h).

New pneumatic control system, automatic fixture one-button lock sample, convenient and labor-saving, superior sealing performance.

- Precise control of temperature and humidity

Temperature control: the semiconductor stabilizer automatically controls the temperature, and the temperature control accuracy is 0.1 ℃.

Humidity control: dual airflow (dry and wet) humidity control, stable humidity, high precision, and humidity accurate to ±2%RH.

- Meet the needs of high-throughput, wide range and high-applicability test ing

Equipped with a single chamber, which is small and flexible, and the test efficiency is high.

Measuring range of 0.002~200 g/(m2·24h), wide range, to meet the test needs of high, medium and low barrier materials, plus suitable accessories, can measure the water vapor transmission of bottles, bags, bowls and other containers.

- Excellent shape, convenient control, real-time visualization of curves

The host is embedded with an 11.6-inch high-resolution color LCD screen, which has a clear view, sensitive control and easy to operate.

The instrument is fully automatic operation, one-button test, automatic judgment, automatic shutdown.

Real-time display of transmission – time, temperature – time, humidity – time, flow – time, voltage – time five sets of curves, curves support preview hidden function.

- Intelligent operating system, global certification

We develop intelligent operating system by ourselves, with modular graphics, flexible setting of test process parameters, intuitive and convenient operation.

Designed according to the GMP appendix “Computerized System”, it has the function of auditing and tracking, and multi-level permission settings for users can meet the requirements of the pharmaceutical industry for data traceability.

Personalized test reports are set on demand, support a variety of formats of data output, support electronic signature function, online submission of audit report function.

- Offline or in-line detection

The instrument comes with its own operating system, which can be tested independently from the computer, and the data is automatically processed. The instrument is equipped with a computer interface, and can also be connected to a computer for online testing.

- Professional calibration service, accurate and reliable data

Our company has approved and issued by the “General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China”: water vapor transmission rate, “National Standard Material Classification Certificate” and “People’s Republic of China Manufacturing Measuring Instrument License”, the standard number (GBW (E)130543 / GBW(E)130544). The instrument is calibrated and verified by the national standard material independently developed to ensure the accuracy, versatility and authority of the test data.

- Laboratory intelligent IoT platform

The instrument can be connected to the IoT platform to achieve digital network management.

Remote authorization to log in to the IoT platform can realize these functions such as managing experimental data, remote diagnosis and troubleshooting etc.

Customers can download the required instrument materials, documents, and operation videos on the platform.

Test Principle of TT-WVTR200 Infrared Method Water Vapor Transmission Rate Tester

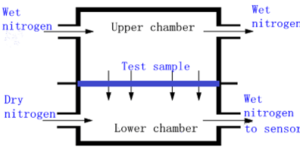

The TT-WVTR200 water vapor transmission rate tester uses the principle of infrared method. The pre-treated sample is fixed in the middle of the test chamber, and the test chamber is divided into high humidity side and low wet side. Compressed air flows on one side of the film and dry nitrogen (carrier gas) flows at a fixed flow rate on the other side. Due to the presence of a humidity gradient, water vapor penetrates from the high-humidity side to the low-humidity side, and the water vapor through the sample is carried to the infrared sensor by flowing dry nitrogen. Parameters such as the water vapor transmittance of the sample are obtained from the electrical signal output by the sensor.

Technical Specifications of TT-WVTR200 Infrared Method Water Vapor Transmission Rate Tester

| Model | TT-WVTR200 |

| Test range | 0.002~200 g/(m2·24h) |

| Test precision | 0.0001 g/(m2·24h) |

| Temperature | 15~45℃ |

| Temperature accuracy | ±0.1℃ |

| Humidity range | (5~90)%RH,100%RH |

| Humidity | ±2%RH |

| Test area | 50.24 cm2 |

| Sample size | Φ100 mm |

| Sample thickness | ≤3 mm |

| Number of samples | 1 Piece |

| Carrier gas | 99.999% N2(user provide) |

| Carrier pressure | ≥0.1 MPa |

| Carrier gas flow | 5~100 mL/min |

| Pneumatic pressure | ≥0.3 MPa |

| Power | 450 W |

| Power supply | AC 220 V, 50 Hz |

Applications of TT-WVTR200 Infrared Method Water Vapor Transmission Rate Tester

| Item | Description | Picture |

| Film | Water vapor transmittance test of various plastic films (PP/PET/PE/PVC/BOPP/CPP, etc.), plastic composite films, paper-plastic composite films, metal composite films, coextruded films, aluminized films, degradable packaging films (PLA/PBAT/PBS, etc.) and other film-like materials. |  |

| Sheet | Water vapor transmittance test of solid pharmaceutical hard sheets (PP/PVC/PTP, etc.), metal composite sheets, rubber sheets and other flakes. |

|

| Paper, cardboard and its composites | Water vapor transmittance test of coated paper, silicone paper, cigarette bag aluminized paper, paper aluminum-plastic composite sheet and other paper and cardboard. |

|

| Medicinal patches | Water vapor transmission performance test of medical plasters. |

|

| Package | Customizable fixtures can be extended to packages such as pharmaceutical polyethylene bottles, sealed bags, pharmaceutical ointment tubes, infusion hoses, plastic trays, etc. |

|

Standard Configurations of TT-WVTR200 Infrared Method Water Vapor Transmission Rate Tester

| Items | Description |

| Standard configuration | Power cord, communication line, sample cutter, sealing grease, ferrule connector, standard membrane, hexagon socket wrench, syringe, sealing ring, syringe sealing ring, fork wrench, cross screwdriver, mouse, metal trachea. |

| Optional | Computer, calibration certificate, air compressor |

| Remark | 1. Standard laboratory environment. 2. Power requirements: 220 V regulated power supply, one socket with three holes and three switches. 3. 3. Computer requirements: standard configuration (Windows 10, with a nine-pin serial port). 4. Other accessories: a bottle of 40 liters of nitrogen (purity 99.999% or more) for calibration, other gases are customized. 5. Drying dish (all samples need to be dehydrated and degassed for 24 hours); 6. Distilled water or purified water. 7. Air compressor. |