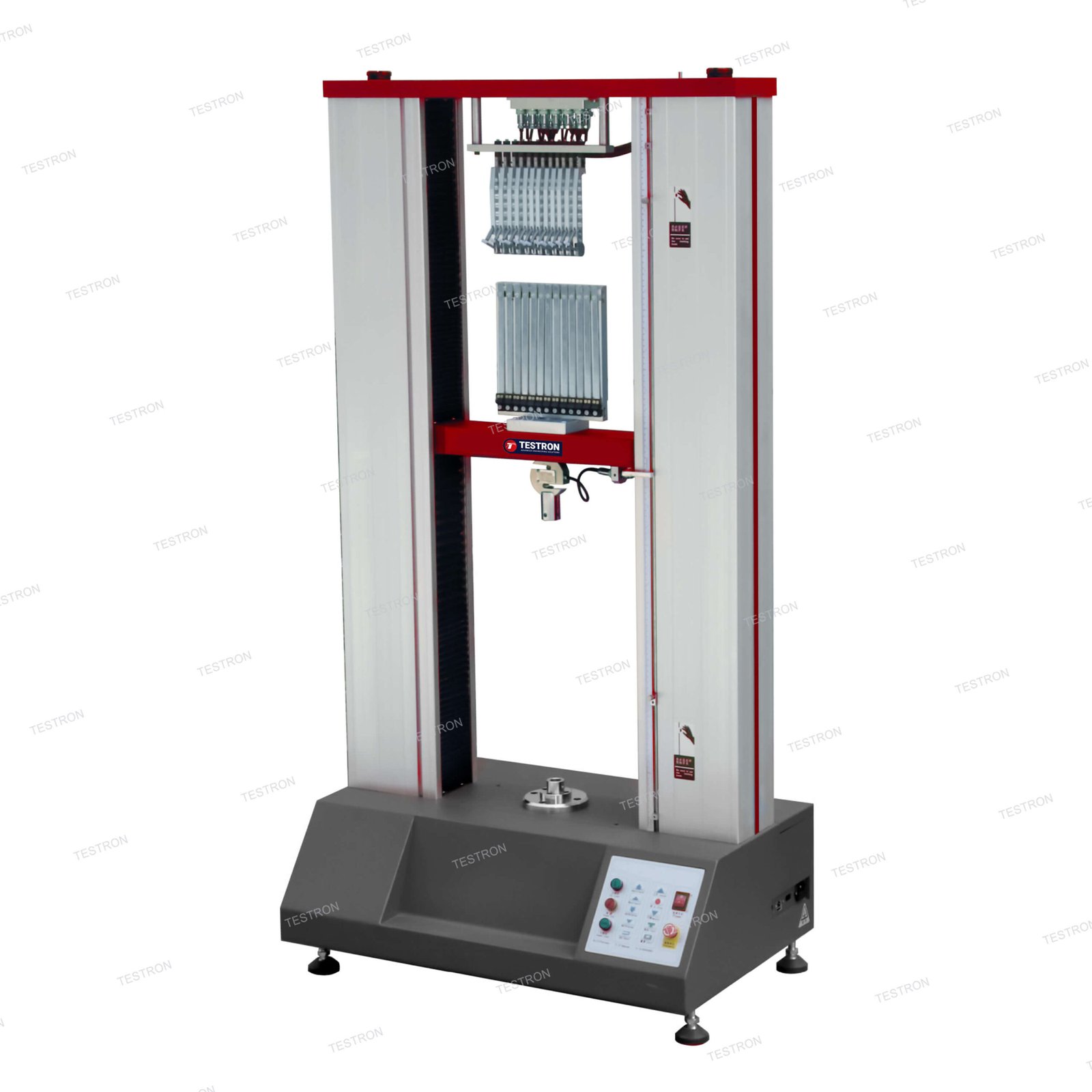

Application of TT-SP2000 2KN Multi-Channel Solar Cell Testing Machine

It is designed for solar photovoltaic industry research and development of a testing Machine.

Test Standards of TT-SP2000 2KN Multi-Channel Solar Cell Testing Machine

GB/T 16491-1996, JJG475-2008, etc.

Features of TT-SP2000 2KN Multi-Channel Solar Cell Testing Machine

- Control mode

Fixed speed, positioning shift, fixed load and other control modes are optional.

- Automatic zero clearing after the test starts

The measurement system automatically zero

- Automatic shift

Automatically switch to the appropriate range according to the load size to ensure the accuracy of the measurement data

- Automatic storage

Automatic storage of test data and test conditions, to eliminate data loss.

- Batch test

For the same parameters of the sample, a batch of tests can be completed in sequence after setting.

- Display mode

Data and curve dynamic display with the test process.

- Curve traversal

After test completion, the curve can be re-analyzed by using the mouse to find out the data corresponding to each point on the test curve.

- Curve selection

Stress-strain, force-displacement, force-time, displacement-time and other curves can be selected for display and printing.

- Unit switching

Force unit: (g, kg, N, lb), stress unit: (kg/mm2, N/mm2, Mpa, lbf/in2), displacement unit: (m, mm, in)

- Security protection

More than 2 ~ 10% of the maximum load, automatic security protection.

It can automatically detect and calculate the mechanical properties of the sample and can also manually intervene in the analysis process to correct the automatic analysis results according to the requirements of relevant standards to improve the accuracy of the data

Software Features of TT-SP2000 2KN Multi-Channel Solar Cell Testing Machine

- Software operation interface design is clear and concise. Formula editing and updating is more user friendly and can be operated by a single person.

- Test speed can be adjusted between 0.05-500mm/min.

- Twenty grid strips can be stretched at the same time. A single side of the battery can be tested in less than 2 minutes.

- The test software can automatically generate test data and can be converted to Word, Excel, PDF format.

- Can store more than 400 query historical data records according to conditions and a separate database can be connected to other computers.

- Multiple stress unit display, can be N, N/mm.

- The real-time negative value caused by the reverse tension of the welding belt during the stripping process will be automatically shielded by the system and will not be displayed.

- Test results can show the peak, median, maximum, minimum, average, defective percentage and welding point proportion.

- Increases the interval tension average calculation, the median method can be selected.

- Increases the optional tension effect judgment (OK/NG).

- Increases the value of tension interval. Each section takes a certain value as the starting point to take a large interval and extends to both sides with the center of the large interval as the center.

- The positioning is shifted to the value interval and the median or average value is taken.

- The software has a separate database, can save multiple groups of data, and view on different computers.

Technical Specifications of TT-SP2000 2KN Multi-Channel Solar Cell Testing Machine

| Model | TT-SP2000 |

| Maximum test force | 50N, 2kN |

| The accuracy level of the testing machine | 0.5 |

| Test force measurement range | 0.2% – 100%FS |

| The relative error of the test force indication value | within ±0.5% of the indication value |

| The resolution of the test force | 1/±500000 of the maximum test force (resolution is unchanged) |

| The relative error of the displacement indication value | within ±0.5% of the indication value |

| Displacement resolution | 0.003mm |

| Force control rate adjustment range | 0.1-5%FS/S |

| Relative error of force control rate | within ±1% of the set value |

| Beam speed adjustment range | 0.05-500mm /min |

| Beam speed relative error | set value within 1% |

| Constant force, constant deformation, constant displacement control range | 0.5%–100%FS |

| Constant force, constant deformation, constant displacement control accuracy | set value <10%FS, set value within ±1% |

| Maximum drawing stroke | 1100mm |

| Effective stretching space (net space) | 680mm |

| Effective test width | 420*420mm |

| Dimensions | 840*500*1650mm |

| Power supply | 220V 50Hz 400W |

| Weight | about 180kg |

Standard Configuration of TT-SP2000 2KN Multi-Channel Solar Cell Testing Machine

| Item | Description | Qty |

| Load sensor | American high-precision sensor 50N*20+2kN*1 | total of 21 |

| Test software | 20+1 channel dedicated test motherboard + 20+1 Chinese and English dedicated software | 1set |

| Control motor | Taiwan Delta B2 servo drive + motor | 1set |

| Deceleration system | Taizhou pepper star precision reducer | 1 pc |

| Transmission screw | Taiwan TBI precision ball screw | 2 pcs |

| Test computer | HP business computer (8G memory +21 inch display) | 1 set |

| Test fixture | Ø 20-channel battery strip test fixture Ø Three-point flexure test fixture | 1 set each |

| Documents | Operation manual, Quality Certificate, Warranty card | each 1 |