The main functions of TT-HBRV Series Electronic Universal Hardness Tester:

- Selection of Brinell, Rockwell and Vickers three test modes

- Conversion scales of different kinds of hardness

- Test results can be saved for checking or be printed out, automatic calculation of maximum, minimum and average value

- With RS232 interface for connecting to the computer

Application of TT-HBRV Series Electronic Universal Hardness Tester:

Suitable for hardened and surface hardened steel, hard alloy steel, casting parts, non-ferrous metals, various kinds of hardening and tempering steel and tempered steel, carburized steel sheet, soft metals, surface heat treating and chemical treating materials etc.

Test Standards of TT-HBRV Series Electronic Universal Hardness Tester:

ISO 6508, ASTM E-18, JIS Z2245, GB/T 230.2, ISO 6506, ASTM E10-12, JIS Z2243, GB/T 231.2, ISO 6507, ASTM E92, JIS Z2244, GB/T 4340.2

Product Details of TT-HBRV Series Electronic Universal Hardness Tester:

|  |  |  |

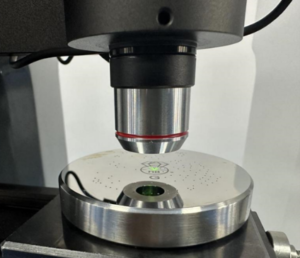

Digital eyepiece (for Vickers, Brinell hardness test) | Built-in cold light source (for Vickers hardness test) | External ring lamp (for Brinell hardness test) | Slipped test table, frictionless screw |

Technical Specifications of TT-HBRV Series Electronic Universal Hardness Tester:

| Model | TT-HBRV1839 | TT-HBRV2450 |

| Rockwell Test Force | 60kgf (558.4N), 100kgf (980.7N), 150kgf (1471N) | 60kgf (558.4N), 100kgf (980.7N), 150kgf (1471N) |

| Superficial Test Force | – | 15kgf(147.11N), 30kgf(294.2N), 45kgf(441.3kgf) |

| Brinell Test Force | 30kgf (294.2N), 31.25kgf (306.5N), 62.5kgf (612.9N), 100kgf (980.7N), 187.5kgf (1839N) | 5kgf(49N), 6.25kgf(61.25N), 10kgf(98N), 15.625kgf(153.125N), 30kgf(294N), 31.25kgf(306.25N), 62.5kgf(612.5N), 100kgf(980N), 125kgf(1225N), 187.5kgf(1837.5N), 250kgf(2450N) |

| Vickers Test Force | 10kgf(98.07N), 20kgf(196.14N), 30kgf(294.2N), 100kgf (980.7N) | 3kgf(29.4N), 5kgf(49N), 10kgf(98N), 20kgf(196N), 30kgf(294N), 50kgf(490N), 100kgf(980N), 200kgf(1960N), 250kgf(2450N) |

| Indenter | Diamond Rockwell Indenter, Diamond Vickers Indenter, ф1.588mm, ф2.5mm, ф5mmBall Indenter | Diamond Rockwell Indenter, Diamond Vickers Indenter ф1.588mm, ф2.5mm, ф5mm Ball Indenter |

| Loading Method | Automatic (Loading/Dwell/Unloading) | Automatic (Loading/Dwell/Unloading) |

| Hardness Reading | Touch Screen Display | Touch Screen Display |

| Test Scale | HRA, HRB, HRC, HRD, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW10/100, HV30, HV100 | HRA, HRB, HRC, HRD, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW10/100, HV30, HV100 |

| Conversion Scale | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBW | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBW |

| Lense magnification | – | Eyepiece: 15X Objective: 2.5X(Brinell),5X(vickers) optional 10X,20X |

| Magnification | Brinell: 37.5×, Vickers: 75× | Brinell: 37.5×, Vickers: 75× optional :150X, 300X |

| Resolution | Rockwell: 0.1HR, Brinell: 0.1HB, Vickers: 0.1HV | Rockwell: 0.1HR, Brinell: 0.1HB Vickers: 0.1HV |

| Dwell Time | 0~60s | 0~60s |

| Data Output | Built-in Printer | Printer |

| Max. Height of Specimen | Rockwell: 230mm, Brinell &Vickers: 160mm | Rockwell: 230mm, Brinell & Vickers: 160mm |

| Throat | 170mm | 170mm |

| Power supply | AC220V, 50Hz | AC110-220V, 50Hz |

| Unit Dimension | 475×200×700mm | 475×200×700mm |

| Packing Dimension | 620×420×890mm | 620×420×890mm |

| Net Weight: 60kg Gross Weight: 84kg | Net Weight: 64kg Gross Weight: 92kg |

Standard Configuration of TT-HBRV Series Electronic Universal Hardness Tester:

| Model | TT-HBRV-187.5 | Model | TT-HBRV-250 |

| Main Unit | 1set | Main Unit | 1set |

| Diamond Vickers Indenter | 1pc | Diamond Vickers Indenter | 1pc |

| Slipped Test Table | 1pc | Slipped Test Table | 1pc |

| Large Plane Test Table | 1pc | Large Plane Test Table | 1pc |

| 15x Digital Measuring Eyepiece | 1pc | 15x Digital Measuring Eyepiece | 1pc |

| Microscope System (includes the inside and outside light) | 1set | Microscope System (includes the inside and outside light) | 1set |

| Hardness Block 60~70 HRC | 1pc | Hardness Block 60~70 HRC | 1pc |

| Hardness Block 80~100 HRB | 1pc | Hardness Block 80~100 HRB | 1pc |

| Diamond Rockwell Indenter | 1pc | Diamond Rockwell Indenter | 1pc |

| ф1.588mm, ф2.5mm, ф5mmBall Indenter

| 1pc each | ф1.588mm, ф2.5mm, ф5mm, ф10mmBall Indenter

| 1pc each |

| Middle Plane Test Table | 1pc | Middle Plane Test Table | 1pc |

| V-shaped Test Table | 1pc | V-shaped Test Table | 1pc |

| 2.5x, 5x Objective | 1pc each | 2.5x, 5x, 10x Objective | 1pc each |

| Hardness Block 150~250 HBW 2.5/187.5 | 1pc | Hardness Block 150~250 HBW 2.5/187.5 | 1pc |

| Hardness Block 20~30 HRC | 1pc | Hardness Block 20~30 HRC | 1pc |

| Hardness Block 700~800 HV30 | 1pc | Hardness Block 700~800 HV30 | 1pc |

| Power Adapter | 1pc | Power Adapter | 1pc |

| Power Cable | 1pc | Power Cable | 1pc |

| Anti-dust Cover | 1pc | Anti-dust Cover | 1pc |

| Printer | – | Printer | 1pc |

| Operating Manual | 1copy | Operating Manual | 1copy |

| Quality and Calibration Report | 1copy | Quality and Calibration Report | 1copy |

| Warranty Card | 1copy | Warranty Card | 1copy |