Whether you’re working in material testing, quality control labs, or downstream processing, the TT‑PPM50 helps you save time, reduce manual error, and maintain compliance—making it one of the best pneumatic press machines available. With its compact footprint, advanced pneumatic design, and operator safety features, this small pneumatic punch press machine fits seamlessly into modern laboratories.

Why Choose TT‑PPM50 Pneumatic Punch Press Machine for Specimen Manufacturing?

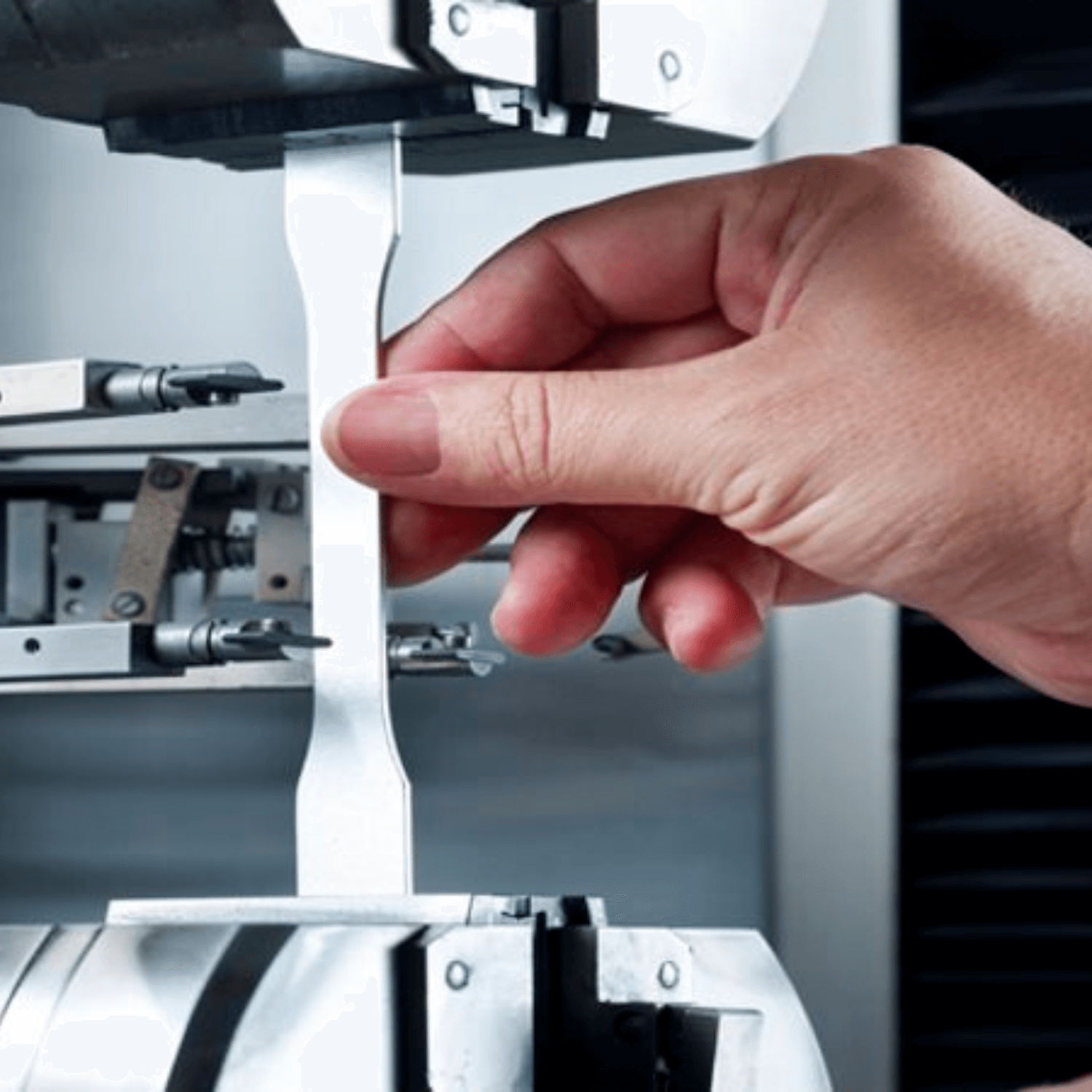

➤Advanced Pneumatic Design for Uniform Punching

Powered by a standard pneumatic cylinder and pressure‑multiplying structure, the pneumatic punching machine achieves a cutting force of 50 kN. With a 20 mm stroke and specimen thickness up to 10 mm, it handles typical test sample dimensions effortlessly.

➤Safety Oriented Operation

Equipped with protective guards and a key start button to prevent accidental engagement, this automatic pneumatic punching machine ensures operator safety while maintaining high speed specimen throughput.

➤Fast and Versatile Specimen Preparation

Interchangeable cutting blades allow rapid changeover between specimen types. From ASTM D638 tensile bars to ISO 527, ISO 6259, and ISO 179/180 test shapes, this unit supports a broad range of standards.

➤Compact Design & Ease of Use

This small pneumatic punch press machine features a footprint of 500 mm × 400 mm × 600 mm and a weight of 120 kg. With minimal air supply requirements (0.6 MPa), it’s easy to integrate into existing lab setups.

Supported Test Standards of Pneumatic Press Machine

The TT‑PPM50 supports widely used material testing shapes according to:-

- ASTM D638 – Tensile testing

- ISO 527 – Plastics tensile tests

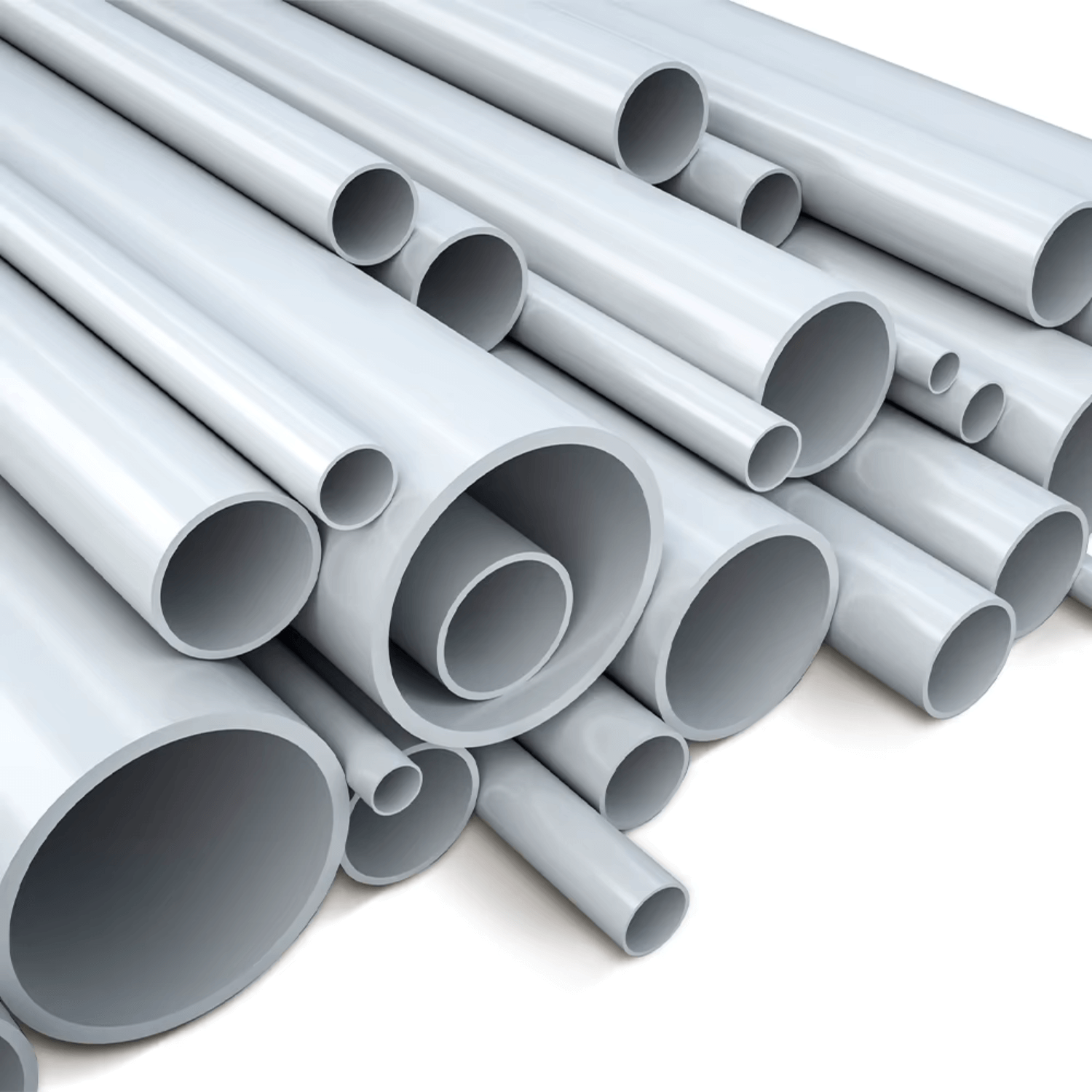

- ISO 6259 – Polymeric pipe tensile testing

- ISO 179 / ISO 180 – Impact specimen preparation

With compatibility across multiple standards, this pneumatic punch press machine meets the demands for standardized specimen preparation.

Ideal Use Cases

Material Testing Laboratories preparing specimens for tensile, tear, and impact testing.

Pipe Manufacturers requiring precise test bar preparation for ISO 6259 compliance.

R&D Facilities validating new materials and formulations.

Technical Specifications of the Pneumatic Punching Machine

| Feature | Specification |

| Max Punching Force | 50 kN |

| Punching Stroke | 20 mm |

| Max Specimen Thickness | 10 mm |

| Dimensions (L×W×H) | 500 mm × 400 mm × 600 mm |

| Weight | 120 kg |

| Air Supply | 0.6 MPa |

| Operation | Manual load, pneumatic punch |

| Cutting Blades | Interchangeable for different shapes |

| Safety Features | Key start, guard interlock |

Testron ensures all equipment meets global standards. The TT‑PPM50 features safety interlocks, energy saving pneumatic systems, and robust metal design for long term durability. Its pneumatic punching press machine manufacturer certification includes quality control certifications to support audits and ISO aligned processes.

To buy pneumatic milling machines or punch presses, contact our sales team. We provide a full quotation—covering machine, blades, shipping, and optional operator training. We also support volume discounts for labs and corporate clients looking for multiple units.

Compared to hydraulic or manual punching alternatives, the TT‑PPM50 offers superior speed, safety, and specimen consistency. Its price is justified by long operational life, low maintenance, and repeatable output—a strong yield of value over cost. For labs evaluating pneumatic punching press machine price, the returns on time savings and reduced error rates make it an excellent investment.

Performance & Operational Advantages of Pneumatic Pressing Machine

High Throughput Testing

Being a pneumatic punching press machine manufacturer and supplier, Testron ensures the TT‑PPM50 is built for high cycle workloads. The machine is ideal for small to large labs that need fast specimen preparation without repeated tool changes.

Precise Positioning & Consistency

A precision travel limit ensures repeatable spec placement. The pneumatic actuation and pressure structure deliver burr free cuts and tight control over sample geometry—critical for repeat testing and calibration labs.

Universal Material Compatibility

From natural rubber to polyethylene film, leather, paper, and thin polymer substrates, this pneumatic press machine handles a wide material range with no change in performance.

Low Maintenance & Operational Cost

With fewer moving parts, easy blade changes, and maintenance-free pneumatic cylinders, the TT‑PPM50 minimizes downtime and offers long-term ROI compared to manual or hydraulic options.

Why Testron Stands Apart as a Pneumatic Punching Press Machine Manufacturer

As a recognized pneumatic press machine manufacturer, Testron provides:-

🢣Local calibration, installation, and training support.

🢣OEM compatibility with cutting knife upgrades and bespoke fixture designs.

🢣Transparent pneumatic punch press machine price and accessory options.

🢣Reliable service, replacement parts, and quick delivery directly from our facility.

Why TT‑PPM50 is the Best Pneumatic Punch Press Machine for Labs

The TT‑PPM50 punching machine combines safety, precision, automation, and flexibility—qualities essential for modern specimen manufacturing. With high throughput, broad shape compatibility, and ISO standard specimen support, this automatic pneumatic punching machine is a reliable partner in material testing workflows. Its compact size belies powerful capability—a smart, cost effective choice for labs requiring efficiency and accuracy in testing.

Call to Action

Prepare test specimens quickly and accurately.

Inquire Now to request the latest pneumatic punch press machine price, cutting blade kits, and calibration support tailored to your application.

Frequently Asked Questions (FAQ)

Pneumatic punch press machine price varies based on blade kits and accessories. Contact us for a quote tailored to your shape and production volume requirements.

Though compact in size, the TT‑PPM50 meets the standards of an industrial abrasion testing machine but in specimen prep context. It’s a robust pneumatic press machine that suits both lab and light industry operations.

Yes. Blades for dumbbell, tear, rectangular, and circular shapes are readily swapped. Custom dies can be produced if required.

A stable supply of 0.6 MPa compressed air is required to drive the pneumatic cylinder effectively and safely.

Minimal training is needed. The automatic pneumatic punching machine is intuitive, with safe startup mechanisms. We offer operator guidance and support.

Routine lubrication, blade sharpening or replacement, and air filter checks are typically required. Testron provides maintenance schedules and spare parts kits if needed.