Why Abrasion Resistance Testing Matters

Abrasion testing is essential in evaluating how a material behaves under mechanical wear. It determines the durability and lifespan of the polymer in real life applications—especially in pipe systems subjected to high flow velocities, mining slurries, and industrial conveying systems. Using a high end abrasion resistance testing machine like TT-AT800 ensures product quality, minimizes field failures, and supports regulatory compliance.

Application Areas of TT-AT800 Abrasion Testing Machine

Resin Manufacturer

Pipe and Plastic Component Testing

Downstream Processing Industries

Quality Assurance Departments

Material Comparison Studies

Research and Development Labs

The TT-AT800 is particularly suitable for conducting comparative testing among various PE-UHMW and PE-HD grades, offering invaluable insights into product formulation, supplier selection, and raw material consistency.

Test Standards of Abrasion Resistance Testing Machine

The abrasion tester complies with major global and regional abrasion testing standards, ensuring accurate and recognized results. These include:-

- ISO 15527

- SH/T 1818-2017

- TCSTM 00173-2019

- DB51/T 2450-2018

By adhering to these standards, the TT-AT800 provides repeatable data for audits, product certifications, and international export quality compliance.

Features of the Abrasion Test Machine

1. Six Synchronized Testing Stations

The instrument features six test stations operating simultaneously. Each station is driven by a synchronous belt and a high precision spindle motor, ensuring uniform rotational speed. This design greatly enhances result comparability and test throughput.

2. High Efficiency Automatic Lifting System

The single capacitor motor lifts and lowers the sample system using a reliable chain mechanism. The machine can stop at any position, allowing easy installation and monitoring. Dual limit switches ensure operator safety and prevent overtravel damage.

3. Immersed Abrasion Test Cup with Anti Spill Design

Each test cup is sealed with a spring loaded lid that prevents slurry leakage during high speed rotation. This robust construction supports long testing hours without mess or maintenance interruptions.

4. Uniform Cooling System for Stable Temperature Control

The six test cups are immersed in a shared water cooled tank, ensuring uniform slurry temperature. The temperature is regulated through a separate refrigeration system with copper tubes, maintaining a variance of less than 1°C between stations.

5. Stainless Steel Construction with Stirring System

The test cups, shafts, and components are fabricated with corrosion resistant stainless steel. The machine is fitted with an external stirring mechanism that maintains consistent slurry concentration and distribution across all stations.

6. Smart Control Panel with Real Time Monitoring

The abrasion tester machine is equipped with a digital panel to display rotational speed, temperature, and test countdown. Users can pre set test durations and monitor real time parameters with ease, improving test accuracy and convenience.

Technical Specifications

| Parameter | Value |

| Model | TT-AT800 |

| Number of Test Stations | 6 |

| Rotation Speed | 800 – 1400 rpm |

| Speed Control Precision | 1% (≥1000 rpm); 10 rpm (<1000) |

| Rotation Display Resolution | 1 rpm |

| Timing Accuracy | 1 second |

| Temperature Display Resolution | 0.1°C |

| Temperature Control Accuracy | ± 0.5°C |

| Test Cup Volume | 35 liters |

| Mortar Ratio | 450g silica sand + 300g water |

| Refrigeration Power | 5.1 kW |

| Power Supply | 220 VAC / 2 kVA |

| Dimensions (L x W x H) | 1.2 x 0.5 x 1.2 m |

| Weight | 220 kg |

- Best abrasion tester for polyethylene durability testing

- Industrial abrasion testing machine designed for long term reliability

- High capacity simultaneous testing to optimize lab efficiency

- Intuitive operation with reduced operator intervention

- Competitive abrasion testing machine price considering its capacity, accuracy, and build quality

- Easily serviceable and low maintenance equipment

Unlike generic or cheap abrasion testing machines, the TT-AT800 is purpose built for demanding industrial use. It combines:-

- Precision of high end abrasion tester machines

- Durability of an industrial grade design

- Flexibility to test under varying temperatures

- Compliance with multiple abrasion testing standards

This makes it ideal for organizations looking to buy abrasion testing equipment that offers long term value and consistent data.

Target Industries of Abrasion Tester Machine

Quality Control Departments in Petrochemical Sector

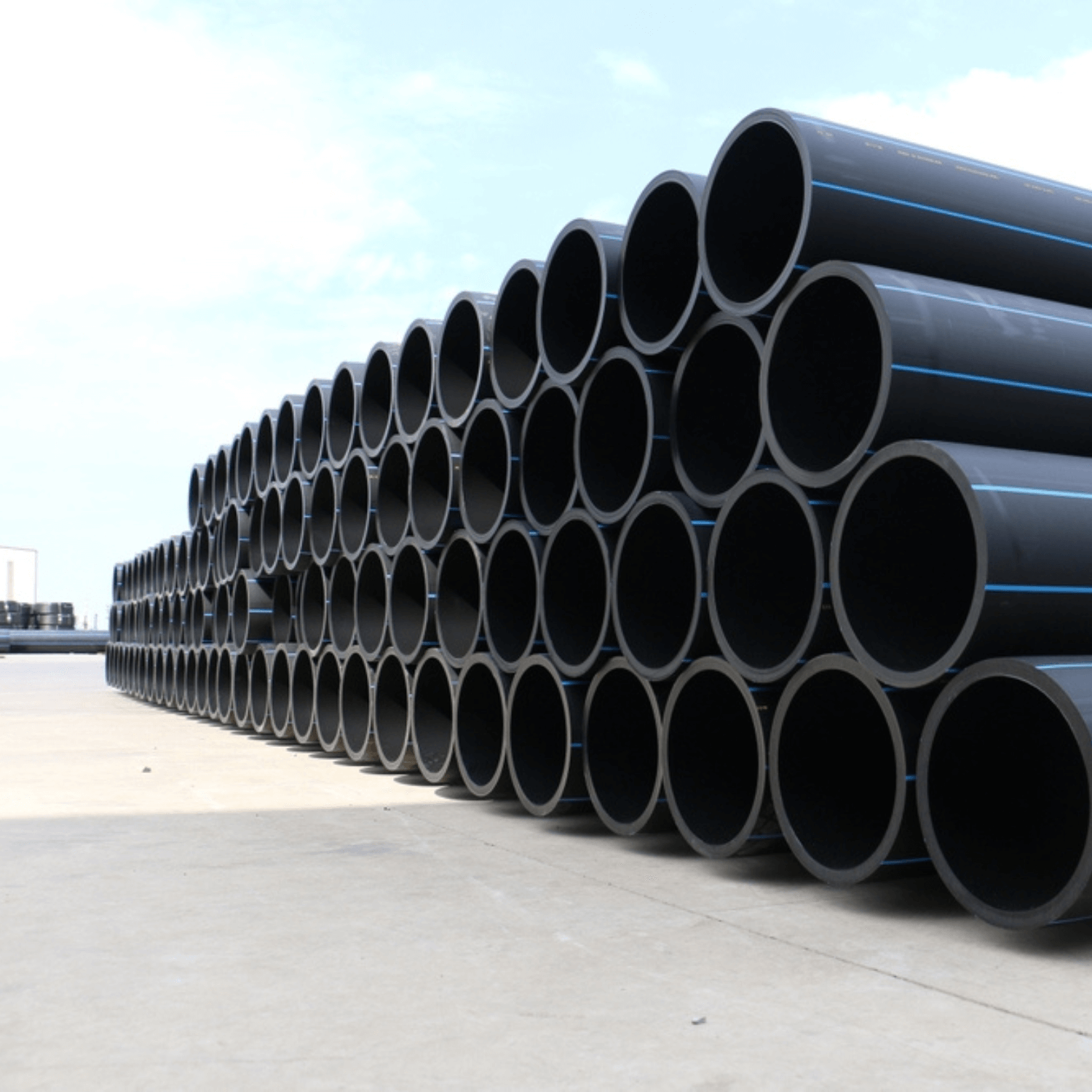

HDPE/PE Pipe Manufacturing

Government Testing Labs

Universities and Research Institutions

Plastic and Polymer Manufacturing

Resin Processing Facilities

Whether you’re looking for the best abrasion testing machine or planning to upgrade from a cheap abrasion test machine, the TT AT800 is engineered to elevate your testing standards.

Why Choose Testron as Your Abrasion Testing Machine Manufacturer?

As one of the leading abrasion testing machine manufacturers, Testron offers end to end testing solutions backed by industry expertise. Our machines are known for:-

- Superior build quality

- Fast service support

- Global test standard compliance

- Availability of spare parts and customization options

We are also trusted abrasion testing machine suppliers to major R&D centers, manufacturing giants, and government institutions across India and abroad.

Cost Efficiency & ROI

While the abrasion testing machine cost is an important consideration, the TT-AT800 offers unmatched value. Its ability to test six samples at once drastically reduces turnaround time, labor, and energy costs. Furthermore, its robust build reduces downtime and servicing expenses—making it an affordable abrasion testing machine in the long run.

Frequently Asked Questions About Abrasion Testing Machine

The machine is designed for polyethylene types like PE-UHMW and PE-HD but can also be customized for other polymers with high abrasion resistance properties.

The TT-AT800 is suitable for both industrial applications and laboratory settings due to its robust build and precision performance.

Standard test durations are typically set to 3 hours, but users can customize the time based on the application or testing standard requirements.

By synchronizing all 6 stations with a single motor and using real time monitoring of speed and temperature, the TT-AT800 ensures uniform test conditions, enhancing result accuracy.

Yes, the panel allows operators to set, monitor, and repeat test parameters to maintain consistency across test cycles.

You can reach out through our website inquiry form or contact our pipe testing equipment sales team. We provide expert consultation to help you choose the right model based on your testing needs.

Final Words

For any organization seeking to enhance quality assurance with abrasion resistance evaluations, the TT-AT800 Abrasion Testing Machine stands out as a reliable, efficient, and standards compliant solution. Its design reflects the best of modern testing principles—combining durability with intelligent automation.

If you’re searching for dependable abrasion test equipment that delivers consistent results while optimizing lab resources, look no further than Testron’s TT AT800. Choose a trusted brand. Choose Testron.