INTRODUCTION: WHY THERMAL SHOCK TESTING IS CRUCIAL FOR MODERN INDUSTRIES

In industries where components and materials must perform under extreme conditions, reliability is not just a requirement—it’s a necessity. Aerospace electronics, automotive sensors, semiconductor devices, and defense-grade materials all experience sudden and drastic shifts in temperature during real-world use. To ensure these products can endure without performance degradation, companies rely on a thermal shock chamber.

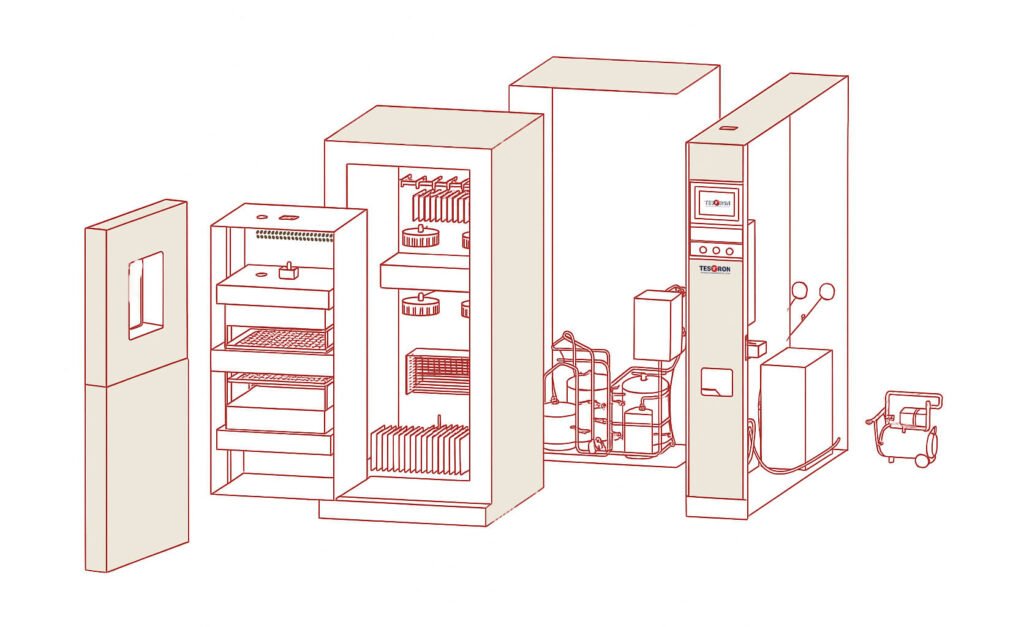

The 2-Zone Thermal Shock Chamber from Testron Group has been designed to deliver precise, repeatable, and accelerated testing by transferring specimens between hot and cold zones automatically. This thermal shock testing chamber uses advanced refrigeration, high-performance heaters, and intelligent controls to replicate sudden temperature fluctuations. By exposing products to repeated cycles of -65°C to +200°C, it helps manufacturers detect hidden defects, structural weaknesses, and performance inconsistencies.

WHY CHOOSE A THERMAL SHOCK TESTING CHAMBER?

A thermal shock test chamber is a critical investment for quality assurance and R&D. Unlike conventional climatic chambers, these chambers expose specimens to rapid and extreme transitions, ensuring products meet the harshest operational requirements.

Benefits of investing in a Testron thermal shock temperature chamber:

- Realistic Stress Simulation:- The thermal shock temperature chamber replicates sudden environmental shifts products face in real-world usage.

- Early Fault Detection:- Identifies defects that are not visible under steady-state conditions.

- Regulatory Compliance:- Aligns with global thermal shock test standards across industries.

- Reduced Product Failure:- Minimizes warranty claims and recalls by ensuring durability.

- Versatility:- Suitable for electronics, aerospace, automotive, and advanced materials testing

- Scalability:- Available in multiple chamber sizes to meet small-scale lab or large-scale industrial testing needs.

TECHNICAL SPECIFICATIONS OF 2-ZONE THERMAL SHOCK TEST CHAMBER

- Temperature Range:- -65°C to +200°C

- Recovery Time:- ≤15 minutes

- Controller:- LCD touch screen with Ethernet and USB connectivity

- Models Available:-

- TT-TS70H – Load capacity 20kg

- TT-TS100H – Load capacity 30kg

- TT-TS150H – Load capacity 50kg

- TT-TS300H – Load capacity 60kg

- TT-TS500H – Load capacity 70kg

- Construction:- Stainless steel interior, insulated chamber walls, large viewing window

- Safety Protection:- Overheat, overload, short circuit, refrigerant monitoring, door interlock system

KEY FEATURES OF THE 2-ZONE THERMAL SHOCK TEMPERATURE CHAMBER

The Testron 2-Zone Thermal Shock Machine is designed to ensure high-accuracy testing while being easy to operate and maintain.

- Smooth Transfer Mechanism:- Vertical sliding basket transfer system ensures specimens move seamlessly between hot and cold chambers.

- Fast Recovery Time:- Temperature recovery in less than 15 minutes enhances testing efficiency.

- Programmable Touch Screen Control:- Intuitive color LCD controller with Ethernet connectivity for remote operation.

- Advanced Refrigeration System:- Mechanical compression refrigeration system with high-efficiency refrigerants.

- Built-in Safety Features:- Overheat, overload, and short-circuit protections with alarms for added operator safety.

- Viewing Window & Internal Lamp:- Large glass window with chamber lighting for easy monitoring.

- Flexible Sample Arrangement:- Adjustable and removable stainless-steel shelves for various specimen sizes.

- CE Certified & ISO17025 Calibrated:- Meets international quality and testing standards.

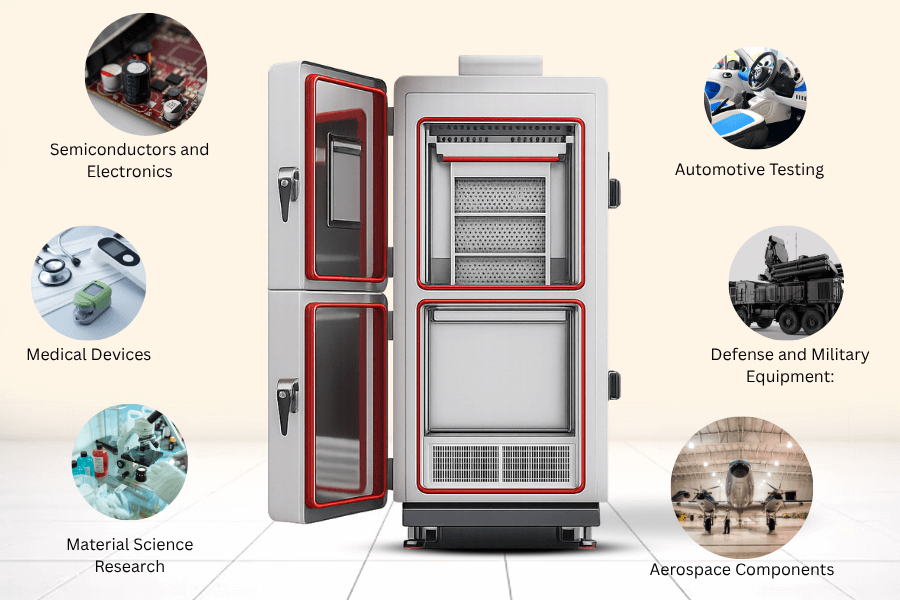

APPLICATIONS OF 2-ZONE THERMAL SHOCK ENVIRONMENTAL CHAMBERS

The versatility of Testron’s thermal shock environment chamber makes it ideal across industries

- Semiconductors and Electronics

Ensures ICs, microchips, and circuit boards can handle sudden temperature variations.

- Medical Devices

Guarantees reliability of life-saving electronic instruments.

- Automotive Testing

Ensures stability of onboard electronics, fuel systems, and sensors under variable climates

- Defense and Military Equipment

Validates mission-critical devices exposed to harsh operational conditions.

- Aerospace Components

Verifies reliability of sensors, connectors, and composite materials used in aircraft.

- Material Science Research

Supports testing of polymers, composites, and advanced coatings.

COMPARATIVE ADVANTAGE – WHY TESTRON LEADS THERMAL SHOCK CHAMBER MANUFACTURERS

| Feature | Testron 2-Zone Thermal Shock Chamber | Standard Chambers | Advantage |

| Temperature Range | -65°C to +200°C | -55°C to +180°C | Wider range |

| Recovery Time | ≤15 minutes | 20–25 minutes | Faster cycles |

| Controller | Touchscreen + Ethernet | Basic digital/analog | Smart & remote |

| Safety System | Multi-layer protection | Basic alarms | Maximum safety |

| Global Reach | Available via thermal shock chamber distributors worldwide | Limited regional supply | Easy accessibility |

To ensure maximum functionality, Testron offers a range of optional accessories with the thermal shock machine:-

- Refrigerants:- High-performance DuPont R404A and R23 refrigerants.

- Heaters:- Nichrome heaters available in multiple wattage options.

- Refrigerant Kits:- PU kits with reusable pressure gauges and hoses.

- Temperature Sensors:- Vaisala HMA6070 sensors with high accuracy (0.01°C).

- Silicone Cable Plugs:- Durable plugs for test cables and connections.

Air Compressor Systems:- Industrial-grade compressors with 80L storage tanks.

When evaluating thermal shock chamber price and features, keep these considerations in mind:-

- Testing Standards Compliance – Ensure the chamber aligns with IEC, JEDEC, or MIL standards.

- Load Capacity – Choose based on your sample size and testing volume.

- Cooling and Heating Speed – Faster recovery improves efficiency.

- Safety Protections – Essential for operator and product safety.

- Automation Features – Ethernet/USB, programmable cycles, and curve logging are must-haves.

- Supplier Reliability – Buy only from reputed thermal shock test chamber manufacturers with global support.

FREQUENTLY ASKED QUESTIONS

A thermal shock test chamber subjects specimens to rapid temperature changes to evaluate reliability and durability under harsh conditions.

The price varies depending on model, load capacity, and features. Testron offers competitive pricing with premium quality.

Electronics, automotive, aerospace, defense, and material testing industries are primary users of thermal shock testing chambers.

Testron provides wider temperature ranges, faster recovery, global distributor networks, and reliable after-sales support.

Yes, Testron offers customization in chamber size, accessories, and controller features.

Testron has a global presence with authorized distributors, ensuring timely delivery and support worldwide.

CONCLUSION: TESTRON – YOUR TRUSTED PARTNER IN THERMAL SHOCK TESTING

The 2-Zone Thermal Shock Test Chamber by Testron Group is the perfect balance of innovation, reliability, and cost-effectiveness. With compliance to international testing standards, competitive cost, and the backing of a trusted manufacturer, Testron ensures your products meet the highest benchmarks of quality.

For R&D teams, quality control managers, and industry leaders seeking the best thermal shock temperature chamber, Testron offers the most advanced solution to validate product durability and reliability.