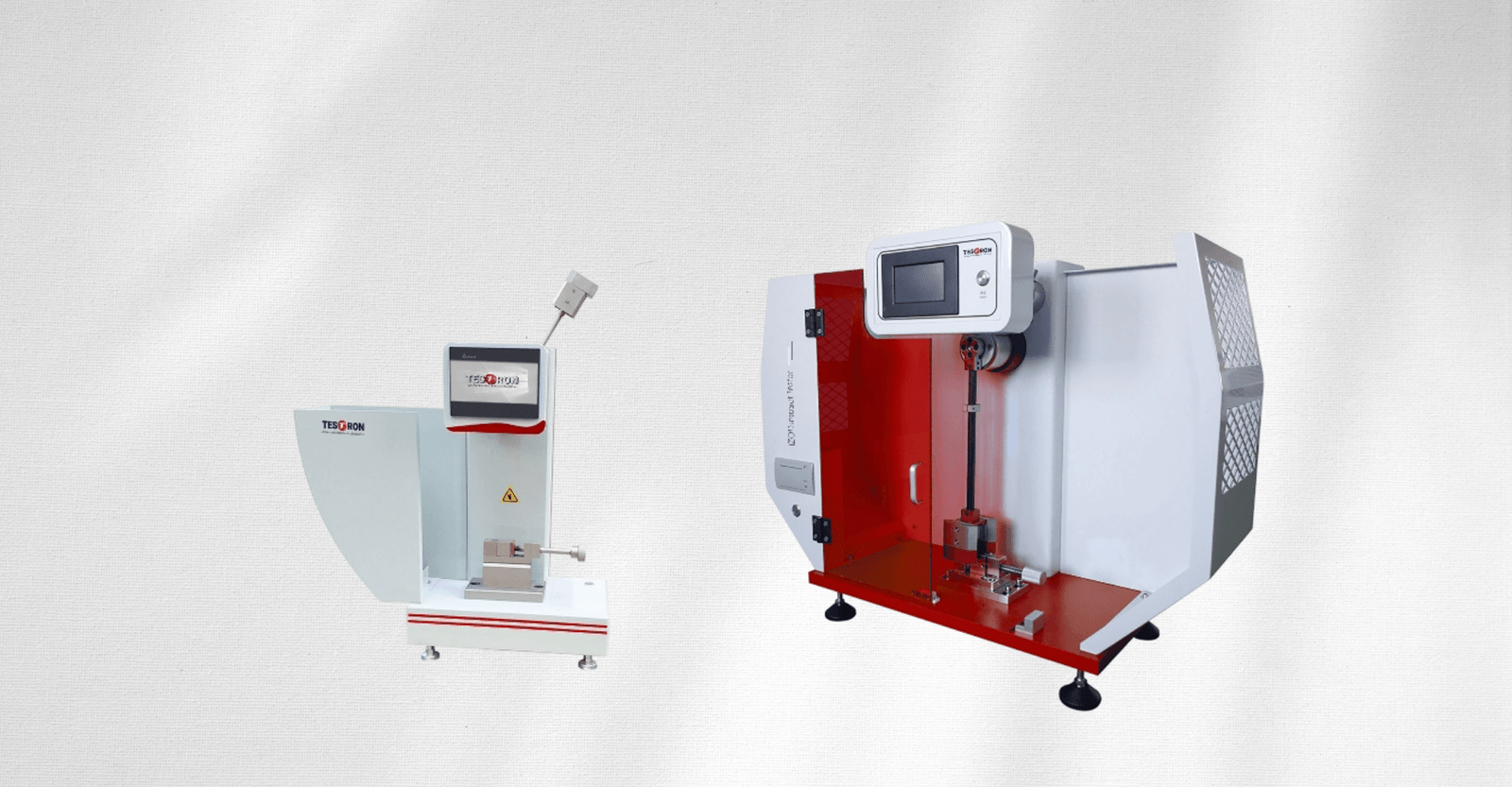

When evaluating an Izod impact testing machine price, consider:-

- Test Standards Compliance – Essential for market approvals.

- Energy Range – Should match the expected toughness of your samples.

- Automation – Digital controls and automatic calculations save time.

- Data Management – Easy export and storage options for traceability.

- Durability – Robust frame and quality components for longevity.

Testron’s pipe testing equipment like Izod pendulum impact tester ticks all these boxes, ensuring your investment delivers lasting value.