Overview: Watercom T Limited’s installation of Testron’s TT-IVS200 intrinsic viscosity tester revolutionizes PET testing in Tanzania by delivering fast, accurate, and automated viscosity measurement. This breakthrough ensures consistent polymer quality, adherence to ISO 1628 and ASTM D4603 standards, and improved lab productivity, positioning Watercom as a regional leader in PET packaging innovation and quality control in Africa.

Introduction

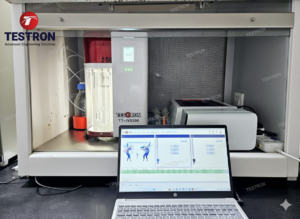

The installation of the Testron TT-IVS200 Intrinsic Viscosity (IV) Tester is the best decision for Watercom T Limited in Tanzania. The reasons to choose Testron’s TT-IVS200 are simple. With our supporting quality control tools, they achieve various goals in terms of hydration and refreshment of their drinking products.

To meet the regulatory standards, various drinks and water content need to pass various testing protocols. Testron’s TT-IVS200 Intrinsic Viscosity (IV) Tester holds the exact capabilities for fast and safe intrinsic viscosity (IV) measurement. The device can directly measure the Intrinsic Viscosity values to improve the level of plastic and rubber testing.

Transform your PET quality control today — Experience accuracy, safety, and innovation with the TT-IVS200 intrinsic viscosity testing equipment!

Watch the TT-IVS200 in action and learn how to measure intrinsic viscosity:

About Watercom T Limited

Watercom T Limited is a leading manufacturer in Tanzania, known for its specialized manufacturing in bottled drinking water and PET packaging solutions.

Impressed by the revolutionary features of Testron’s TT-IVS200 intrinsic viscosity of PET, they decided to join with us and took advantage of the advanced quality control tools.

Through this case study collaboration, Watercom sought to leverage the TT-IVS200 to ensure exact intrinsic viscosity values for PET resins and preforms—essential for maintaining bottle strength, clarity, and recyclability across production batches.

Watercom T’s Challenges Before Installation

Before they had their intrinsic viscosity analyzer in Tanzania, they were facing several critical challenges associated with testing. These issues affected both the production output and quality assurance, such as:

- Manual IV Testing: Traditional methods caused more issues and took more time during the sample preparation and testing sessions.

- Human Error: Manual cleaning of the viscometer might lead to contamination risks.

- Time Constraints: Lengthy testing using the manual methods required more time.

- Inconsistent Data: Collecting testing info was more difficult without automation, and readings were varying.

- Safety Concerns: Operational risks might increase due to direct exposure to certain chemical reagents.

Testron’s Solution: TT-IVS200 Intrinsic Viscosity Tester

The revolution of the PET bottle testing equipment, TT-IVS200 urged the officials of Watercom T to adopt the product as their all-rounder solution. With its amazing features, it completes all the requisite requirements, such as:

- Improved online automatic cleaning.

- Ensure the safety of testing personnel by avoiding the touching of the chemical reagents.

- Directly calculates the following factors, such as:

- Kinematic Viscosity

- Dynamic Viscosity

- Viscosity Ratio, DP (degree of polymerization)

- Relative Viscosity

- Viscosity-average

- Intrinsic Viscosity

- Molecular weight, etc.

- Get all the viscosity design formulas for user convenience.

- Easy to complete serial trend-extrapolation.

- Applicable for the following materials: Applicable material: PET Intrinsic Viscosity (IV) measurement, PET, PLA, PBT, PLA, PA, PGA, PBAT, PC, PVC, CA, Chitin, SB, PAN, TP, etc.

This state-of-the-art intrinsic viscosity measurement instrument ensures every Watercom PET batch meets superior quality standards for transparency, durability, and molecular consistency.

Positive Feedback for Watercom T Limited & Others

The officials and quality control department of Watercom T Limited praised the efficacy and performance of TT-IVS200. The Intrinsic viscosity measuring device comes with precision, ease of use, improved safety, and reliability.

With this tool, the lab has achieved a new level of consistency and safety. Automation minimizes human impact. Now, they can compare PET batches with confidence. TT-IVS200 is an indispensable tool for our daily testing routines.

Also, our previous clients find the intrinsic viscosity tester as the finest tool for quality control measures. Let’s go with their valuable insights:

- Middle East Testing Services L.L.C, UAE: Praises the impact of TT-IVS200V2.

- 3P Gulf Group, Saudi Arabia: Satisfied and thrilled to install the TT-IVS200.

- KANE-EM Industries, Ghana: Improved performance with TT-IVS200 from Testron.

Hear it from global innovators — Request a free demo and adopt TT-IVS200 and take your PET quality assurance to the next level!

Conclusion

The TT-IVS200 Intrinsic Viscosity Tester installation at Watercom T Limited reinforces Testron Group’s role as a leader in polymer testing innovation. Through its precision-driven design, full automation, and robust compliance with ISO 1628 and ASTM D4603 standards which is suggested by Coca Cola and it helps industries ensure consistent, safe, and efficient viscosity measurement processes.

Let Testron guide your quality — embrace smarter, safer, and faster intrinsic viscosity testing with us today!

Related: Discover the Impact of PET Bottle Testing Machines on Reducing Product Failures

FAQs About Intrinsic Viscosity Tester TT-IVS200

• Online cleaning

• Temperature control

• Built-in viscosity equations

These features eliminate human error and ensure consistent, accurate results.