In the dynamic world of manufacturing, ensuring product quality and safety is paramount. This is where Universal Testing Machines (UTMs) come in, a versatile tool used across various industries for testing and mechanical properties of materials. They measure the strength, elasticity, and other properties of various materials. Whether you’re in manufacturing, research, or quality control, choosing the right one can be challenging. Here, we will take you through the process of choosing the best Universal Testing Machine considering factors like testing needs, compliance with American Society for Testing and Materials (ASTM) standards, and budget.

American Society for Testing and Materials (ASTM) Standards

In the field of material testing and quality control, the ASTM (American Society for Testing and Materials) has established a comprehensive set of standards governing the performance and operation of tensile tests on universal testing machines. These standards address various aspects of UTMs, including:

- Specifications: Standards outlining the technical requirements for UTMs, such as load capacity, speed range, and data acquisition capabilities. (e.g., ASTM D3574 for testing flexible cellular urethane foams)

- Calibration: Practices for calibrating the force measuring instruments and extensometer systems used in UTMs to guarantee the accuracy of the test results. (e.g., ASTM E74 for calibrating force measuring instruments)

- Test Procedures: Standards that detail specific testing procedures for different materials using UTMs. These standards specify factors like specimen size, test speed, and data collection methods. (e.g., ASTM D434 for testing tensile properties of plastics)

Here are some relevant ASTM standards for Universal Testing Machines:

- ASTM E74: Practice for Calibration of Force Measuring Instruments and Verifying the Force Indication of Testing Machines

- ASTM E83: Practice for Verification and Classification on Extensometer Systems

- ASTM E1012: Practice for Verification of Test Frame and Specimen Alignment Under Tensile and Compressive Axial Force Application

- ASTM E1856: Standard Guide for Evaluating Computerized Data Acquisition Systems Used in computerized Universal Testing Machines

Significance of ASTM Standards for Universal Testing Machines:

- Consistency and Reliability: ASTM standards provide a common framework for consistent and reliable test results.

- Interlaboratory Comparability: Adherence to ASTM standards allows for meaningful comparisons of test results across different laboratories and locations.

- Quality Assurance: Manufacturers and suppliers can ensure the performance and quality of their products through standardized testing procedures.

- Research and Development: Consistent testing methodologies enable researchers and engineers to develop new materials and improve existing ones.

- Global Acceptance: ASTM standards are widely recognized and adopted globally, enhancing international collaboration and trade in material testing.

Consideration for Choosing a Suitable Universal Testing Machine

Understanding Your Testing Needs

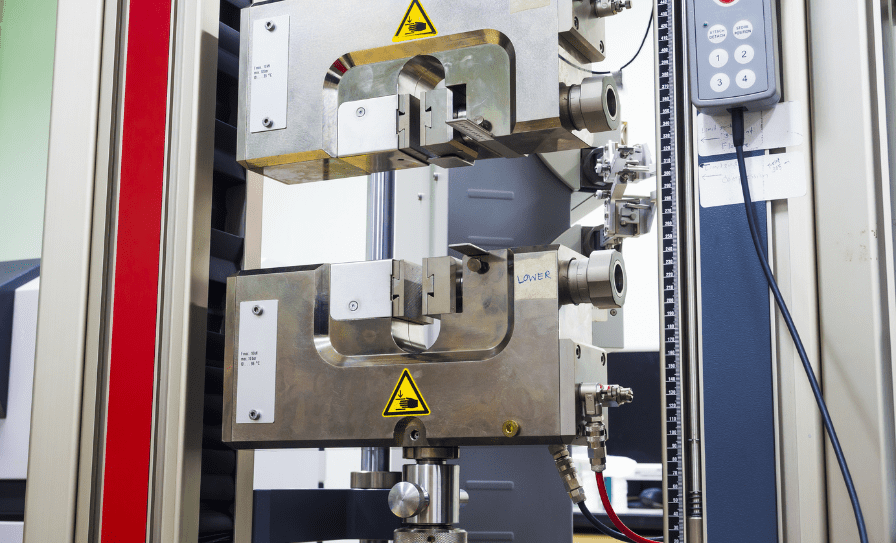

Before diving into the market, identify the types of materials you’ll be testing and the specific requirements and specifications for your application. Different materials require different testing configurations. UTMs can perform various tests, including tensile, compression, flexural, cyclic, and fatigue testing.

Budgeting Wisely

Set a realistic budget for the universal testing machine price range depending on their capabilities and capacity. While getting the most advanced model is tempting, explore cost-effective options that meet your requirements without compromising on quality.

Load Capacity

The UTM’s load capacity determines the maximum force it can apply during a test. Choose a machine with the required load capacity for your tests. This provides a safety margin and prevents overloading the machine, ensuring accurate and reliable results.

Testing Speed and Precision

Consider the required testing speed for your applications. UTMs can perform tests at various speeds. There’s a balance to achieve between speed and precision. High precision might require slower testing speeds for accurate data collection.

Flexibility and Versatility

A UTM should be adaptable to different test methods and accommodate potential changes in your testing needs. Look for a UTM that offers various testing configurations and grips to accommodate different specimen shapes and sizes.

Data Acquisition and Analysis

UTMs collect data during testing. Ensure the UTM has user-friendly data acquisition software for ease of data interpretation. The software should be compatible with your existing data analysis tools.

Machine Calibration and Maintenance

Regular calibration is essential for maintaining the accuracy of your UTM. Understand the calibration process and frequency required by the specific UTM model. Consider the maintenance requirements to keep the UTM functioning correctly.

Types of Universal Testing Machine & Key Features

Based on Load Application

- Hydraulic Universal Testing Machine: Uses pressurized oil for force application. Ideal for high force testing (e.g., metals, concrete). Key features: Powerful, robust.

- Electromechanical UTM: Uses electric motors for force application. Ideal for precise testing across various materials (e.g., metals, plastics, textiles). Key features: Precise, versatile, user-friendly.

- Servo-hydraulic UTM: Combines hydraulics with electronic controls for precise force application. Key features: Highly precise, good for dynamic testing.

- Linear Drive UTM: Uses linear motors for direct force application. Key features: Very fast, low noise, ideal for fatigue testing.

- Resonance Drive Universal Testing Machine: Uses resonant vibration for testing at specific frequencies. Key features: Ideal for dynamic testing of materials with low damping.

Based on Frame Design

- Single Column UTM: Suitable for low force testing (e.g., textiles, films). Key features: Compact, economical.

- Double Column UTM (H-Frame): Offers high stability for medium to high force testing (e.g., metals, plastics). Key features: Rigid, versatile for various tests.

Get in Touch

Looking to buy a suitable Universal Testing Machines, Testron Group is your go-to choice. With our certification seal from SCK Certifications Pvt. Ltd., accreditation from IAS Accredited MSCB 244, International Accreditation Forum (IAF) and ISO 9001:2015, you can trust in our products. Whether you’re seeking a universal testing machine for sale in the USA or anywhere globally, including Europe, Saudi Arabia, India, South Africa, UAE, and China, our expertise is unmatched.

If you need more information, please contact our team info@testrongroup.com