Overview: Testron’s premier fatigue test machine in the UK is engineered for high-capacity anchorage and metal testing. Let’s understand how precision plays an important role that drives many benefits for labs and manufacturing sites. Also, discover working principles and models associated with the fatigue test machines in the UK.

Introduction: The Power of Precision in Testron’s Fatigue Testing Machine

The UK is the hub of many manufacturers who are keen on quality assurance in production, packaging, material testing, and other divisions. Finding the right and durable material testing tools is not a difficult task in the world of the internet and communication.

To bring a competitive advantage to your lab and manufacturing site, users and operators are interested in introducing the finest range of quality control tools. Among the list of the finest manufacturers, Testron’s fatigue test machine in the UK holds a stronger position among users.

This device from Testron ensures that your materials, from aerospace alloys to construction anchors, can withstand the relentless cycle of real-world stress. When you invest in one of the finest servo hydraulic fatigue testing machines, it always gives you maximum ROI.

It’s time to secure the future of your brand’s reputation through unmatched durability and data accuracy that stands the test of time.

Precision that Drives Towards Benefits: Testron’s Fatigue Test Machine in the UK

In the UK, industries prefer more elegant and advanced tools that make their work easier and more efficient all the time. That’s why they choose the right manufacturer and supplier.

In the case of top-rated material testing, Testron Group is a genuine and most-trusted fatigue test machine supplier and manufacturer that deals with the best and elegant products.

Talking about the precision of the fatigue test machine in the UK, Testron has designed the device with advanced sensors that measure the force being applied hundreds of times per second and send that data back to the controller, which instantly adjusts the hydraulic pressure.

Let’s highlight the key features and benefits of using the fatigue test machine in the UK:

- High Dynamic Response: The use of high-performance servo valves allows the machine to switch between tension and compression rapidly.

- Energy Efficiency: Modern servo-hydraulic power units (HPUs) now feature variable-speed drives, which only provide the flow needed for the specific test and significantly reduce energy consumption.

- Frictionless Actuators: High-quality machines utilize hydrostatic bearings in the actuators.

- Improved Thermal Stability: Stable and high-performing oil cooling systems ensure that the hydraulic fluid stays at a constant viscosity, preventing test drift.

- Superior Load Capacity: Capable of handling massive specimens, such as large-scale anchorage systems for UK infrastructure projects.

- Digital Control Integration: Integration with advanced software allows for the automated execution of complex test sequences, reducing human-generated or manual monitoring errors.

Eliminate testing variability and secure repeatable results with Testron! Experience precision like never before with our advanced servo systems and learn why we are the best among fatigue test machine manufacturers.

Models of Testron’s Fatigue Test Machine in the UK

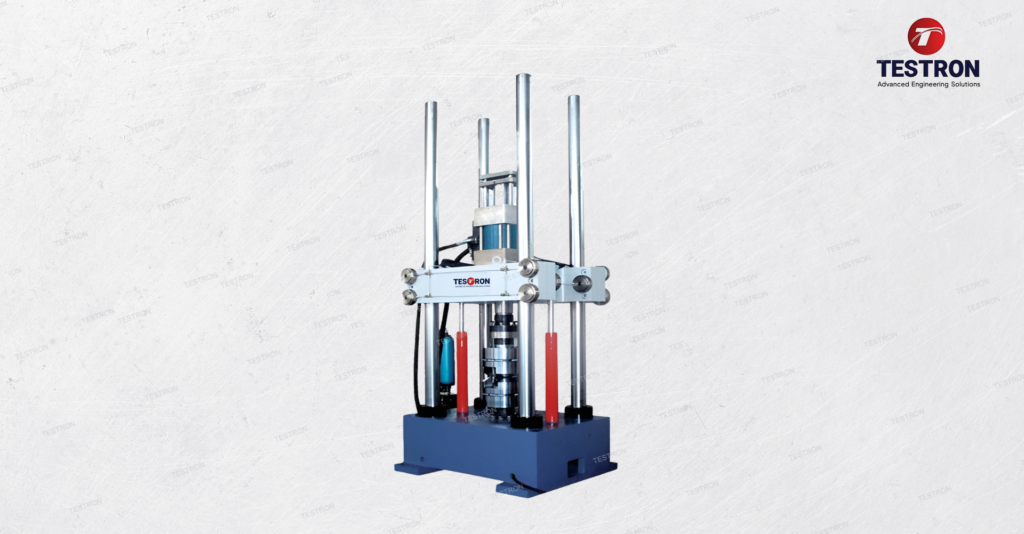

A servo–hydraulic fatigue testing machine from Testron uses fluid power managed by sophisticated electronic valves. This allows for an incredible range of force application, from subtle vibrations to massive structural loads of up to 1000kN, as seen in the TT-WS1000 model.

Based on their capacities, our engineers have categorized the names of the models for the metal fatigue testing machine:

- TT-WS10

- TT-WS25

- TT-WS50

- TT-WS100

- TT-WS200

- TT-WS250

- TT-WS500

- TT-WS1000

Explaining the Fatigue Test Machine Working Principle

After high-quality demand and investments, users always seek to get the best out of the machines efficiently. Firstly, the operators must understand the importance and the metal testing equipment, the fatigue test machine working principle so that they can get the full-phase ROI.

The working principle of a fatigue testing machine involves three primary components:

- The hydraulic power unit (HPU)

- The load frame

- The digital control system

Let’s understand simply about the working of the fatigue test machine in the UK:

- The process begins in the HPU, where high-pressure oil is generated.

- This oil is directed to the actuator located on the load frame.

- A servo valve regulates the flow of oil to the top or bottom of the actuator piston.

- By rapidly switching this flow, the machine can pull (tension) and push (compression) on a specimen.

- The machine evaluates how well a fastening system holds up under cyclic loading, which is a common requirement in UK construction standards.

- The system records peak and valley values for every single cycle.

Unlock the secrets of material durability with high-fidelity waveform simulation. For more product technical details or a quote on fatigue test machine price in the UK, connect with us effortlessly!

Conclusion

Choosing the right fatigue test machine in the UK is a strategic decision that impacts the safety, reliability, and profitability of your engineering projects. The TT-WS1000 Servo Hydraulic Anchorage Fatigue Testing Machine represents the pinnacle of this technology, offering the high-load capacity and dynamic precision required for the most demanding long-term tests.

By prioritizing high-quality fatigue testing machine construction and partnering with reliable fatigue test machine manufacturers, you ensure that your materials are ready for the real world. For advanced recommendations and doubts, chat with us at info@testrongroup.com!

Related: How to Choose the Right Metal Testing Equipment for Your Industry