When purchasing a new environmental chamber, many of the laboratories tend to focus only on the purchasing factors like functionality, performance, and cost-effectiveness. But very few of them take environmental testing chambers installation requirements into account, thus failing to ensure a smooth and successful installation process. Installing a test chamber is no easy task as there are many obstacles that you may have to face during the setup process. To help you minimize setup time and avoid potentially expensive damages, we’ve compiled this comprehensive guide for setting up your new environmental test chamber.

Installation in Compliance to NEMA Standards

The National Electrical Manufacturers Association (NEMA) is a trade association founded in 1926 and is the largest in the United States for electrical equipment manufacturers. It advocates for the industry, publishes standards for electrical products, and specifies the form of US household electrical outlets and plugs.

NEMA established a forum for the standardization of electrical equipment, enabling consumers to select safe, effective, and compatible electrical products. NEMA has approximately 450 manufacturers specializing in the generation, transmission and distribution, control, and end-use of electricity.

NEMA sets standards for various electrical components and aspects that are relevant during environmental test chamber installation. However, NEMA standards can still be relevant during installation in a couple of ways:

- General Electrical Safety: NEMA publishes standards related to general electrical safety, like wiring practices, grounding requirements, and circuit breaker selection (e.g., NEMA Standards Publication WD 6). These can be indirectly applied during installation to ensure safe electrical connections for the chamber.

- Component-Specific Standards: Certain components used within environmental test chambers might have specific NEMA standards. For example, control panels might need to comply with NEMA Type enclosures (e.g., NEMA Standards Publication MG 1) based on their location and potential exposure to environmental conditions.

Preparation for Test Chamber Arrival and Installation

Ensuring a smooth arrival and efficient installation of your environmental testing chambers crucial for minimizing downtime and maximizing testing efficiency. This section focuses on ensuring your environmental test chamber installation adheres to relevant NEMA standards. Here’s a breakdown of key preparation steps to streamline the process:

- Site Selection and Preparation

- Location: Choose a designated area with adequate floor space and weight capacity to accommodate the chamber. Consider accessibility for offloading and future maintenance.

- Clearance: Ensure sufficient clearance around the chamber for proper ventilation, service access, and future modifications. Refer to the manufacturer’s specifications for minimum clearance requirements.

- Utilities: Verify the availability and compatibility of required utilities like power (voltage, amperage), water (pressure, flow rate), compressed air (pressure), and drainage (if applicable) at the designated location.

- Pre-Delivery Coordination

- Review Documentation: Thoroughly examine the manufacturer’s environmental test chambers installation manual and any accompanying drawings. Familiarize yourself with the chamber’s dimensions, weight, offloading procedures, and required tools.

- Schedule Delivery: Coordinate the delivery date and time with the shipping carrier and the installation team well in advance. Ensure someone is available to receive and inspect the shipment upon arrival.

- Offloading Equipment: If necessary, arrange for appropriate lifting equipment (forklift, crane) to safely offload the chamber at the designated location.

- Installation Day Preparation

- Clear the Path: Ensure the path from the offloading point to the final chamber location is clear of obstructions and debris to facilitate smooth movement.

- Assemble Personnel: Have the necessary personnel available on-site, including facility staff, the installation team, and yourself to address any concerns during the environmental test chambers installation process.

- Prepare Tools and Materials: Gather any tools or materials (e.g., leveling shims, electrical connections) specified by the manufacturer for installation.

By following these preparation steps, you can ensure a smooth and efficient arrival and installation of your test chamber, paving the way for successful and timely testing.

Testron Group: Environmental Chamber & Testing Manufacturer

We are TESTRON GROUP, a leading Environmental Chamber & Testing Manufacturer headquartered in the USA, with a strong global presence, regional sales & service offices in Massachusetts, and other key locations worldwide. Our expertise spans across Europe, Saudi Arabia, India, South Africa, UAE, and China, offering innovative, sustainable solutions for industrial and QC material testing equipment.

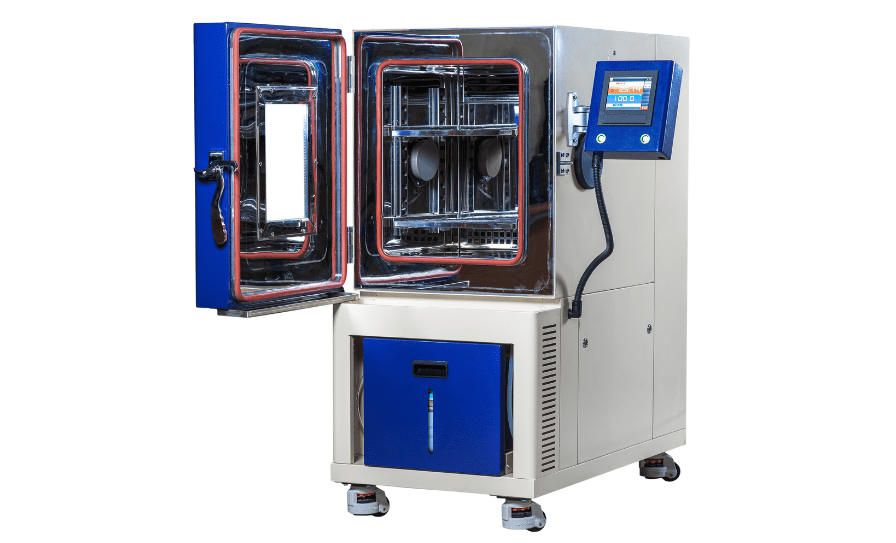

We are your one-stop shop for the best environmental test chamber price and reliable industrial machinery to maximize your output. We offer a wide range of chambers to meet your specific testing needs. Here’s a look at what Testron Group has to offer in environmental testing chambers:

Temperature & Humidity Test Chambers

Simulate extreme hot, cold, and humid conditions to assess a product’s performance and durability. Ideal for electronics, pharmaceuticals, and automotive components.

Thermal Shock Test Chambers

Rapidly cycle temperatures between hot and cold to identify weaknesses in materials caused by thermal stress. Perfect for testing materials used in aerospace, construction, and packaging.

Salt Spray Corrosion Test Chambers

Recreate harsh saltwater environments to evaluate a product’s resistance to rust and corrosion. Essential for marine equipment, fasteners, and appliances.

Accelerated Weathering Test Chambers

Simulate the effects of sunlight, rain, and temperature extremes to predict a product’s lifespan outdoors. Valuable for testing building materials, furniture, and coatings.

Dust and Rain Test Chambers

Replicate dusty and wet environments to assess a product’s functionality and weather resistance. Crucial for electronics used in construction, agriculture, and outdoor settings.

Ozone Test Chamber

Evaluate how a product reacts to ozone exposure, which can degrade certain materials over time. Important for testing rubber products, tires, and electronics.

SO2 H2S CO2 Corrosion Chamber

Simulate industrial atmospheres containing these corrosive gasses to assess a product’s resistance. Valuable for testing pipelines, oil and gas equipment, and chemical processing components.

Walk-in Test Chambers

Provide a large capacity for testing entire products or assemblies under controlled environmental conditions. Perfect for testing automotive interiors, furniture systems, and large electronic devices.

Industry Drying Ovens

Offer precise temperature control for drying, curing, and baking a variety of industrial materials. Essential for electronics manufacturing, composite production, and food processing.

Inquire Now

Our expertise in environmental testing chambers is unmatched across USA (United States of America). We are one of the leading manufacturers and suppliers with a global presence spanning, Europe, Saudi Arabia, India, South Africa, UAE, and China., offering top-quality environmental test chambers for sale. Inquire now and experience the excellence of Testron Group.

If you need more information, please contact our team info@testrongroup.com