Executive Summary

A differential scanning calorimetry instrument in the USA is one of the most critical analytical tools used by industry professionals in the USA to understand how materials respond to temperature changes. From polymers and pharmaceuticals to composites and advanced chemicals, DSC technology provides precise insights into melting behavior, crystallization, glass transition temperature (Tg), oxidation induction time (OIT), and thermal stability.

For manufacturers, R&D engineers, and quality managers in cities such as Houston, Chicago, New York, Los Angeles, and San Jose, a reliable differential scanning calorimetry instrument in the USA is not optional—it is essential for compliance, product optimization, and competitive advantage.

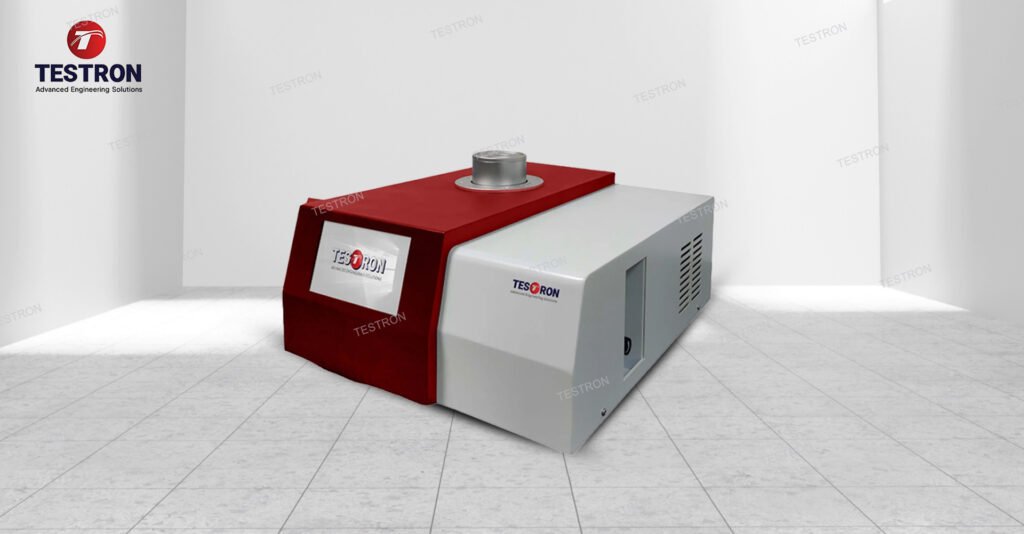

At Testron Group, we design and supply best-in-class differential scanning calorimetry equipment, including the compact intelligent DSC and the next-generation TT-DSC300, engineered for high accuracy, repeatability, and seamless laboratory integration.

This practical guide explains how DSC instruments work, where they are used, how to select the right system, and why Testron is a trusted differential scanning calorimetry instrument manufacturer and supplier in the USA.

Introduction:- Why DSC Instruments Matter in Modern Industry

In today’s data-driven manufacturing environment, understanding thermal behavior is a decisive factor in product performance, safety, and compliance. Whether you are developing a new polymer compound, validating pharmaceutical stability, or ensuring consistency in production batches, Differential Scanning Calorimetry instrumentation delivers measurable, actionable insights.

A differential scanning calorimetry machine allows laboratories to evaluate material transitions under controlled heating or cooling conditions—faster and more accurately than traditional thermal analysis methods.

As a leading differential scanning calorimetry instrument in the USA supplier, Testron Group supports industries across the USA with DSC solutions designed for research, quality control, and industrial scalability.

Download the DSC Selection Guide

What Is a differential scanning calorimetry instrument used in the USA?

A Differential Scanning Calorimetry (DSC) instrument is a thermal analysis device that measures the difference in heat flow between a test sample and a reference material as temperature changes over time.

What Does DSC Measure?

- Melting temperature

- Crystallization temperature

- Glass transition temperature (Tg)

- Oxidation induction time (OIT)

- Heat capacity

- Thermal stability

These parameters are essential for material selection, process optimization, and compliance with ASTM and ISO standards.

Differential Scanning Calorimetry Instrument Principle

Understanding the differential scanning calorimetry instrument principle is key for effective application.

How DSC Works

- A sample and reference are placed in identical pans

- Both are subjected to a controlled temperature program

- Heat flow differences are continuously measured

- Thermal events appear as peaks or shifts in the DSC curve

Why This Matters

- Endothermic events (melting, evaporation)

- Exothermic events (crystallization, curing)

- Precise thermal fingerprints for material characterization

This principle makes differential scanning calorimetry DSC equipment indispensable for accurate thermal analysis.

Key Components of a DSC Instrument

Component | Function |

Furnace | Controlled heating and cooling |

Sensors | Measure heat flow differences |

Sample pans | Hold material samples |

Cooling system | Enables sub-ambient testing |

Software | Data acquisition and analysis |

Testron’s DSC systems are designed for high thermal sensitivity and minimal baseline drift, ensuring consistent results.

Differential Scanning Calorimetry Instrument in the USA Applications

1. Polymer & Plastics Industry

- Determining Tg and melting points

- Evaluating crystallinity

- Comparing material grades

2. Pharmaceutical Industry

- Drug-excipient compatibility

- Polymorphism analysis

- Stability studies

3. Chemical Manufacturing

- Reaction kinetics

- Cure behavior

- Oxidation resistance

4. Packaging & Films

- Seal integrity

- Thermal durability

- Shelf-life prediction

5. Automotive & Aerospace

- Composite material analysis

- Heat resistance validation

- Performance under thermal stress

Across New York, Detroit, Houston, and Los Angeles, DSC instruments play a critical role in advanced manufacturing.

Request a DSC Application Consultation

Types of Differential Scanning Calorimetry Equipment

| Type | Typical Use |

| Heat Flux DSC | Routine QC and R&D |

| Power Compensation DSC | High-precision research |

| Modulated DSC | Complex polymer analysis |

Testron offers advanced differential scanning calorimetry instrumentation in the USA optimized for industrial reliability.

Testron’s Best-in-Class DSC Instruments

Compact Intelligent DSC

- Space-efficient design

- Ideal for routine QC

- Fast thermal response

TT-DSC300 Differential Scanning Calorimeter

- Next-generation accuracy

- Wide temperature range

- Advanced software analytics

Both models deliver repeatable, high-resolution thermal data, making them trusted choices among DSC professionals.

DSC Instrument Specifications That Matter

When evaluating differential scanning calorimetry instrument specifications, focus on:-

- Temperature range

- Heating/cooling rate

- Sensitivity

- Baseline stability

- Software capability

Typical DSC Specifications Table

| Parameter | Industrial Standard |

| Temperature Range | Sub-ambient to high temperature |

| Heating Rate | Variable, programmable |

| Sensitivity | Micro-watt level |

| Atmosphere Control | Inert or oxidative |

Differential Scanning Calorimetry Instrument Price Considerations

While the differential scanning calorimetry instrument price is an important factor, professionals should evaluate total value, not just upfront cost.

Factors Influencing DSC Instrument Cost

- Performance accuracy

- Automation level

- Software features

- Service & support availability

- Manufacturer credibility

Testron provides competitive DSC pricing with long-term reliability and USA-focused technical support.

Get a Customized DSC Quote on info@testrongroup.com

Why Choose Testron as Your DSC Instrument Manufacturer

As one of the trusted differential scanning calorimetry instrument manufacturers, Testron Group delivers:-

- Precision-engineered systems

- Proven industrial performance

- Intuitive user interfaces

- Strong after-sales support

- Global compliance readiness

Our DSC instruments are used by laboratories across San Jose, Boston, Chicago, and Houston.

Integration Into Industrial Workflows

Testron’s differential scanning calorimetry machine integrates seamlessly into:-

- R&D laboratories

- Quality control departments

- Pilot plants

- Production validation environments

This ensures consistent data flow from research to manufacturing.

Download DSC Technical Brochure

Schedule a Live Product Demo

Speak With a Thermal Analysis Expert

Request Pricing & Specifications

Compliance & Standards Supported

Testron DSC equipment supports testing aligned with:-

- ASTM thermal analysis standards

- ISO material testing protocols

- Industry-specific QA guidelines

This ensures acceptance across regulated industries.

Conclusion:- Why DSC Instruments Are Essential for Industry Professionals

For industry professionals in the USA, a differential scanning calorimetry instrument is not just a laboratory tool—it is a strategic asset. It ensures material reliability, regulatory compliance, and performance consistency across the product lifecycle.

With best-in-class DSC instruments, competitive pricing, and expert support, Testron Group empowers laboratories and manufacturers to make confident, data-driven decisions.

Request a Demo of Testron DSC Equipment

Partner With a Trusted DSC Instrument Manufacturer