TESTRON delivers quality industrial chillers for the plastic processing industry, Include, injection molding, blow molding, thermoforming, extrusion, etc.

Blow molding (the technique of blowing hollow bodies) is an important method of polymer processing that is used to make hollow items.

In this method, a molten or parison tube is inserted into a mold and forced to expand by exerting internal pressure until it reaches the mold’s walls, where the plastic material solidifies. Although blow molding is most commonly used to make bottles and vials, the number of items made with this simple and very inexpensive technology is growing all the time, including vehicle spoilers and fuel tanks. High pressures (up to 5.5 bar) and low working temperatures (usually between 7°C and 10°C) are required for the process.

Below are our cooling system for Blow Molding Machine:

GCEVO- Air Cooled Chillers

The GCevo series, the natural evolution of the GC range, comprises air-cooled process water chillers with a cooling capacity ranging from 4 to 122 kW. The range can be applied in the most diverse production areas and in this latest evolution it presents many functional advantages.

AXEVO – AXEVO-FC- Air Cooled Chillers

The AXevo line integrates into a single solution the latest technologies introduced by EC, providing high levels of efficiency and reliability without compromising the specific applications which contributed to the success of the previous AX line, and provides the basis of this new evolutionary series of process water chillers.

ADXEVO – ADXEVO-FC- Air Cooled Chillers

The ADXevo line integrates into a single solution the latest technologies introduced by EC, providing high levels of efficiency and reliability without compromising the specific applications which contributed to the success of the previous AX line, and provides the basis of this new evolutionary series of process water chillers.

ICETEMP- Water Cooled Chillers

Precision thermo-chiller

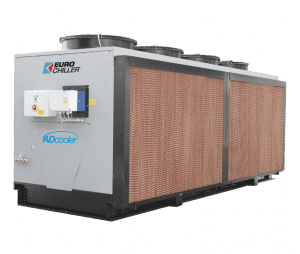

ADCOOLER- Dry Cooler

ADcooler is an adiabatic dry-cooler using the ambient air to cool the process water. If we take advantage of the evaporation of water resulting from the use of the adiabatic pads, we get an inlet air temperature to the exchange batteries (dry-cooler) which is much lower than the ambient one. So it happens that the ADcooler system cools the water at a temperature that is always lower than the ambient one, with no contamination or consumption of process water.

DCOOLER- Dry Cooler

The Dcooler Series is a dry-cooler designed by EC to provide the market with a high level of innovation at a low cost.

Explore Our Complete Range chillers for Blow Molding machines Here

Contact our team to learn more about our machines and services info@testrongroup.com