High-temperature drying ovens are an integral part of quite a variety of manufacturing processes, which range from testing materials to finishing a product. These industrial and laboratory drying ovens are precious tools for industries, with contents as divergent as electronics, automotive, pharmaceuticals, and food processing. High-temperature ovens can ensure quality and reliability in finished goods by removing moisture, curing materials, or testing product durability. High-temperature industrial ovens provided by Testron have dependable performance for arduous manufacturing and lab applications – one is the TT-6300 Drying Oven, and the other is the TT-9023A Laboratory Drying Oven.

This article discusses the advantages of high-temperature drying ovens in manufacturing, the available kinds, and how Testron’s state-of-the-art drying ovens can improve your quality control methodologies.

Why High-Temperature Drying Ovens are Essential in Manufacturing

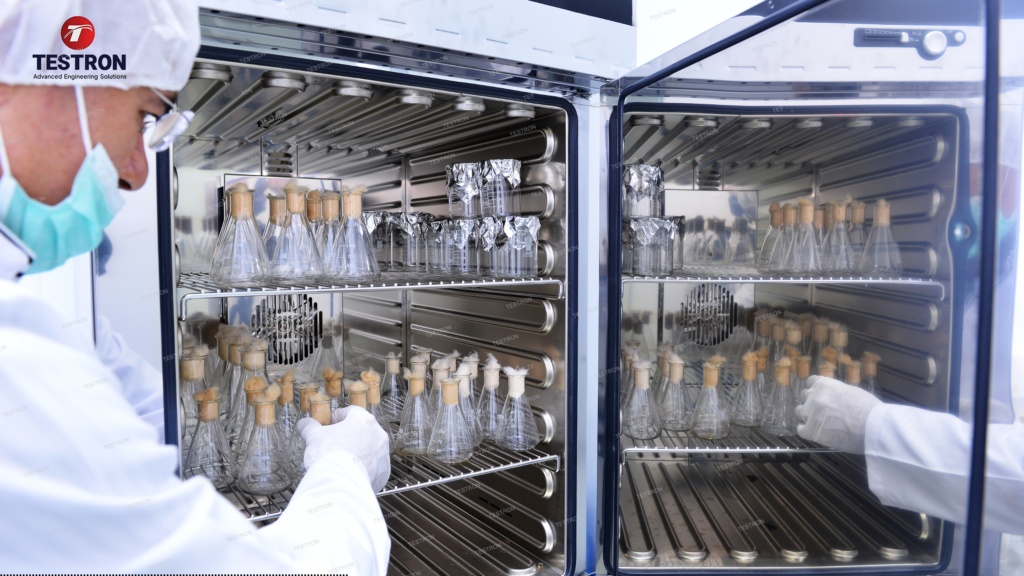

High-temperature ovens provide a controlled heating environment to reach the temperatures necessary for moisture evaporation, curing of coatings, and materials testing. Such industrial ovens-high temperatures have become integral to many manufacturing processes because they offer consistency in controlling temperatures, durability, and adaptability. Manufacturers speed up production, enhance quality, and accommodate industry requirements- a necessary course of action to maintain competitive advantage.

Key Benefits of Using Industrial Drying Ovens

1. Accelerated Drying and Curing Processes

Industrial drying ovens are highly efficient in speeding up drying and curing cycles, which is ideal for coating adhesives and composite industries. Shorter drying and curing cycles also translate to shorter production cycles, allowing manufacturers to better cope with strict production schedules and productivity standards. One great example of such an oven is Testron’s TT-6300 Drying Oven, which consistently provides high-temperature conditions to allow fast and uniform curing, ideal for demanding production conditions.

2. Enhanced Product Quality

The laboratory ovens have a high temperature that allows precise temperature control, which would be essential for holding quality. For example, in pharmaceutical and food manufacturing industries where conditions of exact temperature are required, laboratory ovens ensure that constant quality prevails in every production batch coming from their machine. In using highly advanced devices such as Testron’s TT-9023A Laboratory Drying Oven, problems caused by uneven drying or curing of products can be avoided from arising.

3. Versatility Across Applications

High-temperature ovens have other applications besides mere drying. They are applied for heat treatment, sterilisation, aging, and durability testing. Such multiple possibilities of use in industry make manufacturers perform several applications within a single piece of equipment, thus making industrial dry ovens a worthwhile investment in the long run. Whether it is a laboratory for material testing or to cure large batches within a factory, high-temperature ovens offer versatile solutions for different phases of the production chain.

4. Improved Energy Efficiency

Most modern industrial oven manufacturers focus on energy efficiency to reduce running costs. The contemporary high-temperature oven is designed with proper insulation and optimised airflow to achieve quick heating to high temperatures and maintain these temperatures using less energy. Testron’s High-Temperature Industry Drying Ovens focus on energy efficiency and performance to enable businesses to reduce their carbon footprint and enhance productivity.

5. Safety in High-Temperature Applications

Managing high-temperature equipment is always a safety-related issue, especially in a manufacturing environment where ovens run continuously. The more advanced oven commonly found in such applications carries numerous safety features: automation control of temperature, overheat protection, alarms, etc. They protect the product and operator so that even extended exposure to high heat can be safely managed.

Types of High-Temperature Drying Ovens

Choosing the right high-temperature oven depends on the specific needs of the application. Here are a few categories of drying ovens commonly used in manufacturing and laboratory applications.

Bench-Top Drying Ovens :

compact for small lab or confined spaces, bench-top drying ovens provide point-of-use temperature control for drying small samples and components; commonly utilised in material testing labs.

Walk-In Drying Ovens:

Large-volume operations can be held by high-capacity walk-in drying ovens, allowing manufacturers to hold large quantities. Auto and aerospace are some of the industries that require big or bulky articles to be dried, as high-capacity ovens are meant for such types of requirements.

Vacuum Drying Ovens:

Vacuum drying ovens operate based on the theoretical concept of lesser air pressure for faster drying and prevention of oxidation. These vacuum drying ovens are relatively frequently used in electronics and chemical industries since one often needs to dry sensitive materials without exposing them to the air at relatively low temperatures.

Conveyor Drying Ovens:

Conveyor drying ovens are primarily used in batch drying operations and often form part of automatic production lines. These ovens allow for high-output operations and work well in rapid-turning industries like food processing.

Applications of High-Temperature Drying Ovens in Various Industries

Several different industries are using high-temperature drying ovens based on their quality control and production requirements, which are industry-specific:

Automotive:

Parts of cars are hot-treated, with cured coating and endurance tests of automobile auto parts to ensure they are kept for extreme scenarios.

Electronics:

Drying ovens help remove moisture from components before assembly in the electronics manufacturing industry to prevent damage and prolong electronic parts’ life.

Pharmaceuticals:

Laboratory ovens at a high temperature are used in sterilising equipment, drying chemical samples, and compound stability; therefore, they are widely employed in the safe production of pharmaceuticals.

Textiles:

Textile manufacturers use them to set dyes, cure coatings, and test the quality of fabrics on finished products for durability and colourfastness.

Food Processing:

Industrial oven drying of food products eliminates the moisture content, dries out packaging materials, and tests shelf stability.

How to Choose the Right High-Temperature Oven for Your Needs

First, many factors go into selecting a high-temperature oven: temperature needs, volume capacity, and specific application. Consider these factors when choosing a high-temperature drying oven:

Temperature Range:

The oven shall attain the temperature requirements of your process, whether curing, sterilising, or heat-treating.

Capacity and Size:

Consider the capacity an oven has to fit the scale of operation. For more extensive heavy processes, industrially sized ovens may have to be used, while bench-top models can suffice for smaller lab operations.

Energy Efficiency:

The appliances must save energy if the equipment is continuously running.

Safety Features:

Determine if the oven has built-in overheat protection features, alarm signals, and automated shut-offs to safeguard the operator and products.

Reliability and durability:

Testron’s investments in high-quality equipment from reputable industrial drying oven manufacturers ensure durability and almost minimal maintenance on the investment.

Why Testron’s High-Temperature Drying Ovens are a Top Choice

Testron industrial and laboratory drying ovens have performed well in the demands of modern manufacturing. The products include the TT-6300 Drying Oven, designed for longitudinal reversion testing, and the TT-9023A Laboratory Drying Oven, which provides consistent temperature control, energy efficiency, and safety. This company has focused on the product’s usability and reliability in multiple applications ranging from small-scale lab testing to full-scale industrial processing.

Enhance Your Manufacturing Process with Testron’s High-Temperature Ovens

Do you require improved manufacturing performance through precision drying solutions? Testron’s high-temperature industrial and laboratory drying ovens come with the quality, reliability, and safety required by your production line. Contact Testron today for more information on our range of drying ovens and learn how we can help support your quality control needs.

Contact the experts at Testron today to receive the perfect drying oven for your operation!

FAQ

High-temperature dryers are used for drying, curing, sterilizing, and heat treatment in various industries, such as automobiles and pharmaceuticals

A laboratory dryer is more petite and used explicitly to test with precision, but an industrial dryer is more significant and used for large-scale processing.

Energy efficiency reduces operating costs, which is beneficial to businesses running an oven continuously, hence reducing the environmental impact.

For safe operation, it should have overheat protection, alarms, automated shut-off, and uniform temperature control.

Some variables include temperature range, capacity, energy efficiency, and unique applications. It depends on your particular needs and which Testron’s team is there to assist you in choosing the best oven.