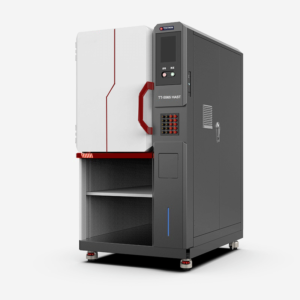

Technical Specifications TT-5565HAST High Pressure Accelerated Aging Test Chamber:

| Items | Not more than 80Kg per cubic meter of studio volume. | ||

| Total Volume load | Not more than 1/5 of the volume of the working room. | ||

| Total Load Area | Not be greater than 1/3 of the cross-sectional area of the working chamber there | ||

| Volume | About 150L | ||

| Inner size | Ø(diameter)550 mm x D(Depth)650mm (Drum type pressure inner tank) | ||

| Exterior size | W900 mm x H1552mm x D1500 mm (Excluding the protrusion of the machine) | ||

| Test Conditions | Natural cooling or air purging | ||

| Temperature range | +105℃ ~ +135℃ (at 100% relative humidity) | ||

| Temperature fluctuation | ±0.5℃ | ||

| Temperature range | +105℃ ~ +135℃ (at 100% relative humidity) | ||

| Temperature uniformity | ≤±3.0℃ | ||

| Temperature deviation | ≤±3.0℃ | ||

| Humidity range | HUM unsaturated test mode: 65~100%RH STD saturation test mode: 100%RH | ||

| Humidity fluctuation | ±3.0%RH | ||

| Humidity deviation | ±5.0%RH | ||

| Temperature change rate | Heating rate: +25℃ ~ +135℃, average 3℃/min (no load) | ||

| Load | N/A Note: Measured at room temperature +25℃ with no load, temperature and humidity performance test is measured according to the relevant regulations of GB/T 2424.5 or IEC60068 -3-5; The sensor is placed at the air outlet of the air handling unit. | ||

| Pressure range | +0.2 ~ 200Kpa *Absolute pressure: 100 ~ 300Kpa | ||

| Pressure deviation | ≤±2 kPa | ||

| Boost time | Atmospheric pressure to 200 Kpa within 20min | ||

| Ability range | |||

| Noise | ≤65 decibels (dB) | ||

| Testing standard | IEC-60068-2-66 | ||

Chamber Structure of HAST High Pressure Accelerated Aging Test Chamber

| Structural features | Integral drum pressure vessel structure complies with national safety container standards. The inner box design of the drum prevents condensation on the top and dripping water. | ||

| Insulation maintenance structure | Outer layer of high-quality cold-rolled steel plate Middle insulation layer is made of temperature-resistant foam insulation material Inner chamber SUS316 | ||

| Exterior Material | High-quality cold-rolled steel plate, surface electrostatic powder baking paint | ||

| Interior Material | SUS316 stainless steel plate; the whole inner tank is fully welded and welded | ||

| Thermal insulation layer | Superfine glass wool insulation layer, flame retardant grade A1 | ||

| Door | Single open the door, open to the left. Flush-mounted rotary handle | ||

| Unit parts | Water storage tank, cooling air outlet, automatic water replenishment pump, water replenishment solenoid valve, water level box, drain hole | ||

| Manual pressure relief valve | Manual pressure relief valve for emergency pressure relief | ||

| Standard configuration | Sample rack: 2 layers of stainless-steel sample rack Mobile casters (with foot cup) 4 pcs | ||

| Air conditioning system | |||

| Features | Regulation and control: forced convection and humidity regulation of the fan blades | ||

| Air circulation | High-power fan driven by external motor with stainless steel shaft, external fan motor; The air is driven by a motor and fully flows through the heater. After being fully heated to the required temperature value, the air circulates inside the box, and the test piece is exchanged through convection. | ||

| Fan motor | Low voltage asynchronous high temperature resistant long axis motor | ||

| Centrifugal wind wheel | Multi-blade centrifugal circulating fan, aluminum alloy blades | ||

| Heating humidifier | Armored cross tube heater, PID+SSR control, equipped with independent over-temperature protection temperature switch After the heater is energized, the surface temperature will increase. The temperature of the convective air increases after passing through the heating wire, which expands the heat to the air in the box and the test piece, and plays the role of heating and heating. The heating power is precisely controlled by the PID algorithm, and the output power is adjusted through the solid-state relay | ||

| Control System | |||

| Specification | Regulation and control: forced convection to adjust temperature and humidity | ||

| Controller | In-house 7-inch color touch screen intelligent fuzzy controller *Operating system: In-house KM-5160 pressure, temperature and humidity version | ||

| Screen display | The temperature and humidity setting (SV) actual (PV) value is directly displayed; It can display the execution program number, segment number, remaining time and cycle times, and display the running time; Program editing and graphic curve display; Fixed-point or program action status display; 7-inch LED backlit display screen | ||

| Resolution | Temperature: + 0.01℃. Humidity: + 0.1%. Time: 0.01min | ||

| Set up range | Temperature can be set range: -100 ~ 200 ℃ (note that it is not the equipment performance range); Adjust according to the temperature working range of the equipment (upper limit +5℃, lower limit -5℃) Humidity conditions: 0 ~ 100%RH | ||

| Program capacity | Usable program capacity: maximum 10 groups. Usable memory capacity: 50 steps per group. Commands can be executed repeatedly: each command can be cycled up to 99 times | ||

| Communication Interface |

| ||

| Safety protection system | Independently adjustable electronic over-temperature protection device for test chamber | ||

| Circulation fan | Overheat protection relay, overload protection. | ||

| Heater | Air conditioning channel limit over-temperature protection: mechanical bimetallic principal over-temperature protector | ||

| Humidification system | Humidification heating tube over-temperature protection (dry burning), abnormal water supply, and abnormal drainage protection | ||

| Pressure protection system | Automatic exhaust and pressure relief when the pressure in the box exceeds the maximum working value 1) Double protection of independent mechanical pressure gauge and upper limit pressure setting in controller 2) Safety relief valve (automatic pressure relief valve, can be manually controlled) | ||

| Door lock protection | The position sensor judges whether the box door is closed in place and locked, otherwise the equipment cannot run | ||

| Main switch | Equipment leakage protection, overload and short circuit protection | ||

| Control circuit | Overload and short circuit protection | ||

| Alarm | When the above protection occurs, the equipment stops running, and sends out an audible and visual alarm. At the same time, the fault location and its cause and solution are displayed on the instrument | ||

Site Condition

Operating Environment

- Environment temperature: 5℃-35℃;

- Relative humidity: no more than 85%R.H

- Atmospheric pressure: 80kPa~106kPa

- Flat and vibration-free ground;

- Choose well-ventilated, no direct sunlight or direct radiation from other heat sources;

- There is no strong air flow around: when the surrounding air needs to flow forcibly, the air flow should not be directly blown to the box;

- There is no strong electromagnetic field around;

- No high-concentration dust and corrosive substances around

Power source specification

- Single-phase power supply 220V AC (±10%)

Single-phase wire + protective ground wire, grounding resistance ≤ 4Ω.

- Power frequency: 50±0.5Hz

Ground protection

- Grounding resistance ≤ 4Ω.

Power supply wiring

- This chamber has 3 meters standard power cord.

- Customers need to prepare a dedicated fusion-free switch for the equipment.

Humidification water supply

Customers need to provide pure water with conductivity below 20us / cm (manually add water

Technical Specifications of HAST High-Pressure Accelerated Aging Test Chamber:

| Items | Brand | ||

| Touch Screen | In-House | ||

| Circuit Breaker | Schneider | ||

| AC contactor | Schneider | ||

| Thermal relay | Schneider | ||

| Phase sequence relay | Swiss Carlo | ||

| Intermediate relay | Omron or Swiss Carlo | ||

| Solid state relay | Swiss Carlo | ||