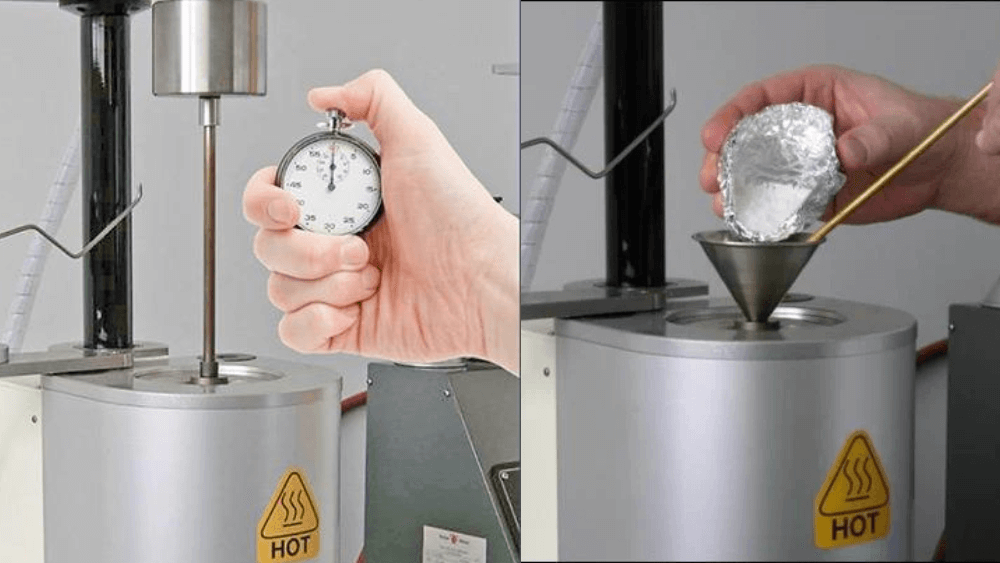

In today’s competitive manufacturing landscape, global standards compliance is non negotiable. Melt Flow Index ( MFI ) testing plays a pivotal role in aligning plastic materials with regulatory and performance benchmarks such as ISO 1133, ASTM D1238, and GB/T 3682. For manufacturers operating in sectors like automotive, aerospace, packaging, and consumer electronics, ensuring that their raw materials meet the required melt flow rate ( MFR ) and melt volume rate ( MVR ) thresholds is critical.

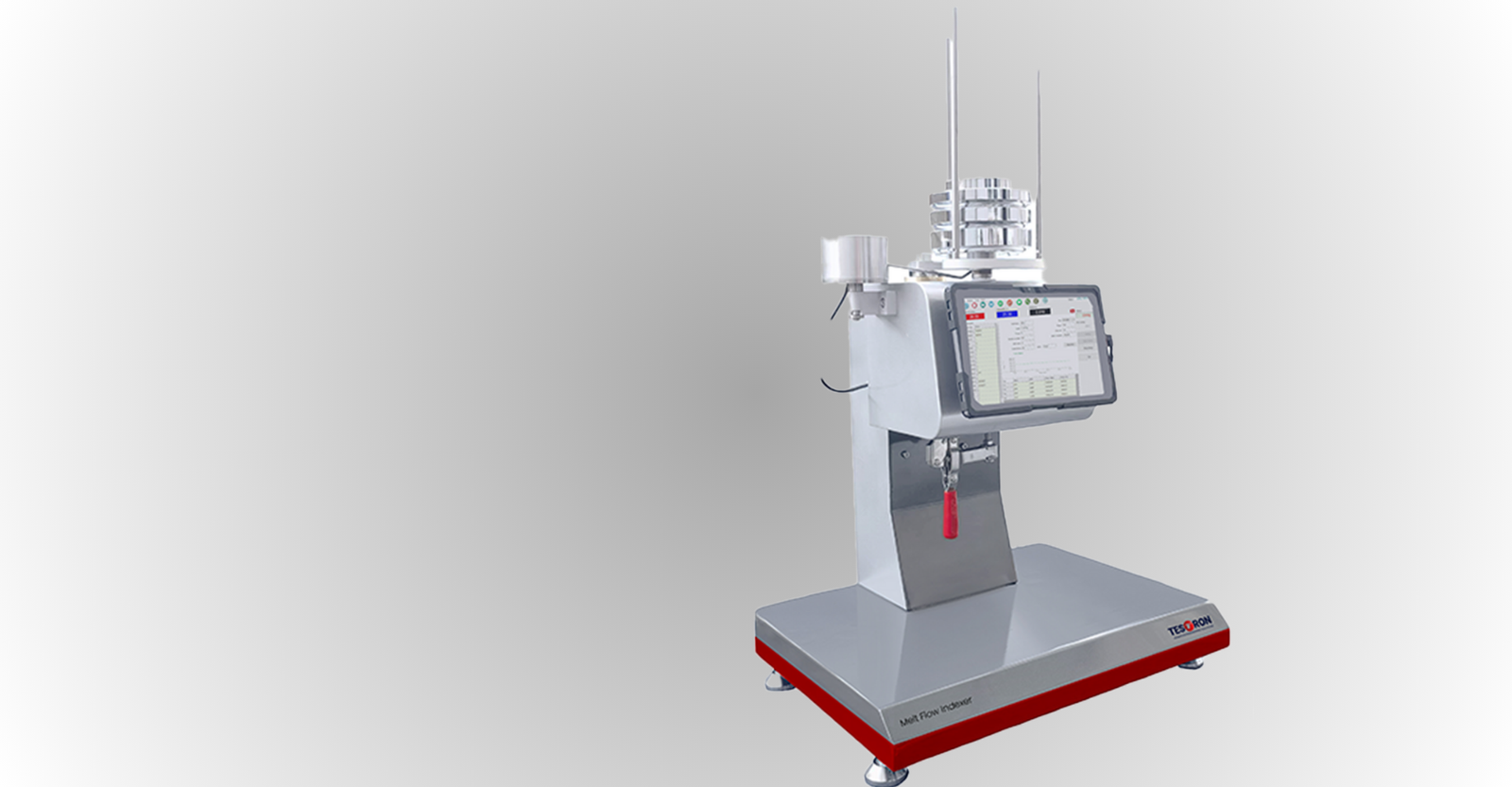

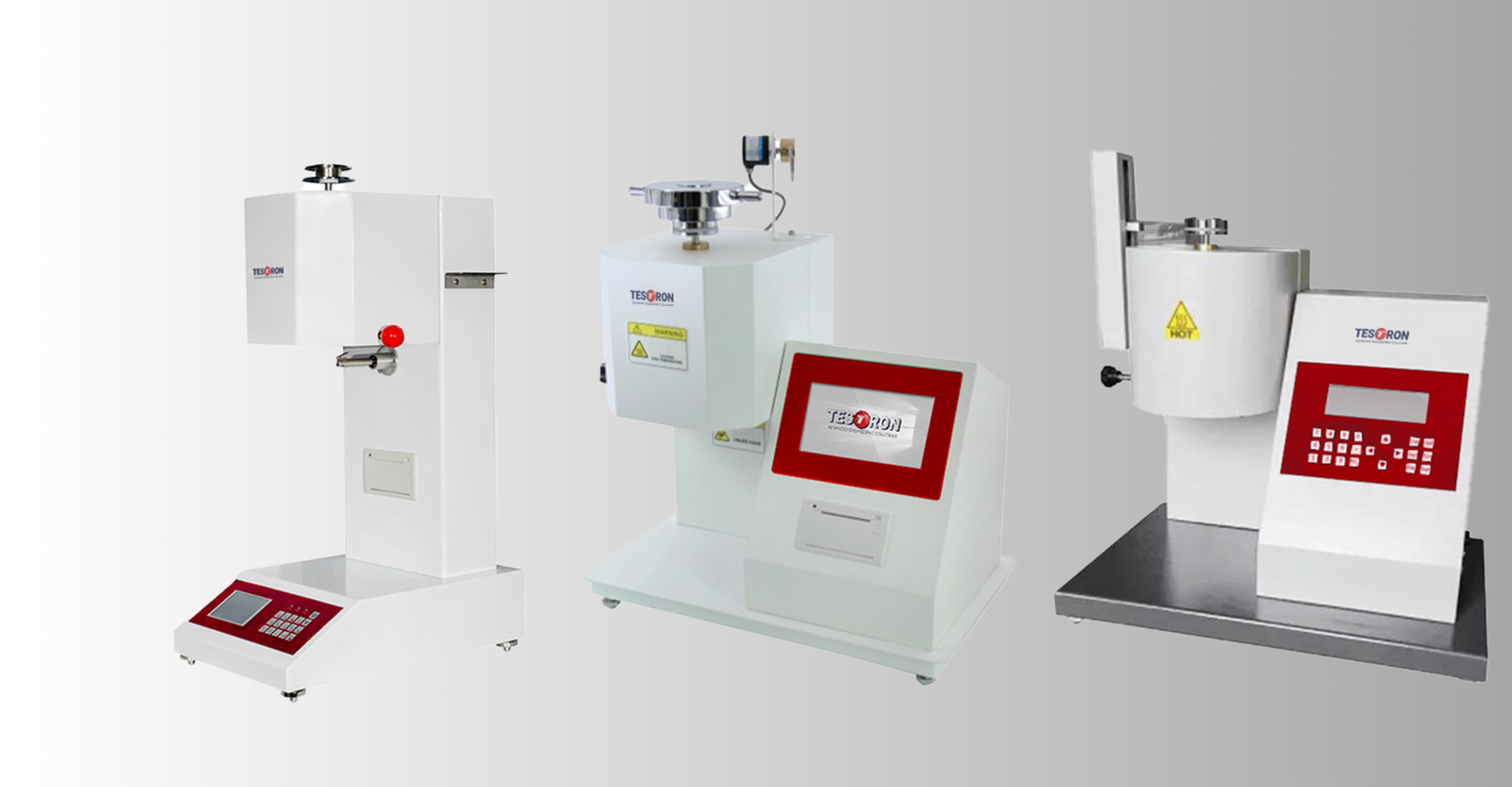

Testron’s melt flow index machine streamline this process by offering automated testing, precise digital controls, and compliance ready documentation. Whether you’re an OEM verifying resin specifications or a third party laboratory offering certification testing, our machines empower your quality control process. They facilitate the generation of consistent, reproducible results, critical for passing audits, maintaining certification, and ensuring downstream production efficiency.

Moreover, with increasing global focus on sustainability, recycled polymers are entering the mainstream. MFI testing becomes even more critical in assessing whether these recycled resins meet quality standards comparable to virgin materials. Testron’s equipment ensures that every polymer, new or recycled, is properly characterized for its melt behavior , thereby supporting environmentally responsible manufacturing without compromising quality.