Application of TT-BDL2 Falling Dart Impact Tester

It is suitable for free falling dart method impact resistance testing of plastic films and sheets. Such as PE/PP composite film, aluminized film, aluminum-plastic composite film, nylon film and plastic sheet for food and drug packaging bags, etc.

Test Standards of TT-BDL2 Falling Dart Impact Tester

ISO7765-1, ASTM D1709, JIS K7124, GB/T 9639, GB/T 15267

Features of TT-BDL2 Falling Dart Impact Tester

- With color-touch screen

- Equipment has a mechanical shape and user-friendly design making it simple and convenient to operate

- One machine with three purposes: Test method A, method B and single-chip test mode design

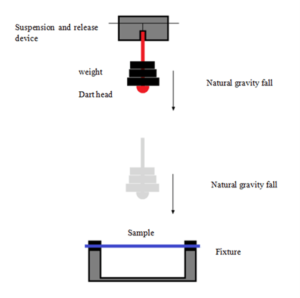

- Adopts the principle of electromagnetic suction and hanging that can be automatically release to avoid system errors due to human factors

- Test process is intelligent, improves work efficiency

- The specimen is pneumatically clamped and released, reducing errors and test time

- Easy display of data parameters on the LCD system

- Automatically identifies test data system and calculates without manual intervention

- Built-in printer to print test reports

- The instrument can perform data query and query the results of each set of data; can support 30 sets of data queries.

Technical Specifications of TT-BDL2 Falling Dart Impact Tester

| Model | TT-BDL2 |

| Measurement methods | Method A, Method B, single chip test |

| Test Range | Method A: 50~2000 g; Method B: 300~2000 g |

| Single chip test range | 20 g, 25 g, 40 g, 60 g, 80 g |

| Resolution | 0.1 g |

| Dart head size | Method A: Φ38 mm±1 mm, Method B: Φ50 mm±1 mm |

| Weight size | Method A: Φ30 mm, Method B: Φ45 mm |

| A method weight

| Method A weight: 5g, 8 pieces each for 15g, 30g, 80g 16 pieces for 120g (Method A) |

| B method weight

| Method B weight: 8 pieces each for 15g, 45g, 90g 9 pieces for 180g (Method B) |

| Impact height | 1500 mm/660 mm |

| Fixture | Pneumatic clamp, outer diameter 150 mm, inner diameter 125 mm |

| Gas source | Compressed air, 0.6~0.8 MPa |

| Air supply interface | Φ6 mm gas tube |

| Dimensions | 510 mm×440 mm×1300 mm |

| Weight | 50 kg |

| Power supply | AC 220 V,50 Hz / 75w |

| Power | 75W |

Test Principle of TT-BDL2 Falling Dart Impact Tester

Select the test method (Method A or B) and estimate an initial mass and Δm value, then start the test. If the first sample is damaged, use weight △m to reduce the mass of the falling body; if the first sample is not broken, use weight △m to increase the mass of the falling body. Continue with the samples in sequence. In short, using weights to reduce or increase the mass of the falling body depends on whether the previous sample is damaged. After testing 20 specimens, calculate the total number of damages N. If N is equal to 10, the test is completed; if N is less than 10, continue testing after adding specimens until N equals 10; if N is greater than 10, continue testing after adding specimens until no damage occurs. until the total number equals 10, and finally the system automatically calculates the impact result.

Note: The initial value m is the mass of the dart head when it falls for the first time, and △m is the mass added or subtracted after each test).

Standard Configuration of TT-BDL2 Falling Dart Impact Tester

- Main unit

- Gas pipe

- Diameter reducing straight connector (grey)

- Sample holder

- Impact head,

- Cross screwdriver

- Hexagonal wrench

User provide: Gas source